vertebral body fusion

A fusion device and vertebral body technology, applied in the field of vertebral body fusion device, can solve the problems of affecting the treatment effect and being unable to adjust the vertebral body fusion device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

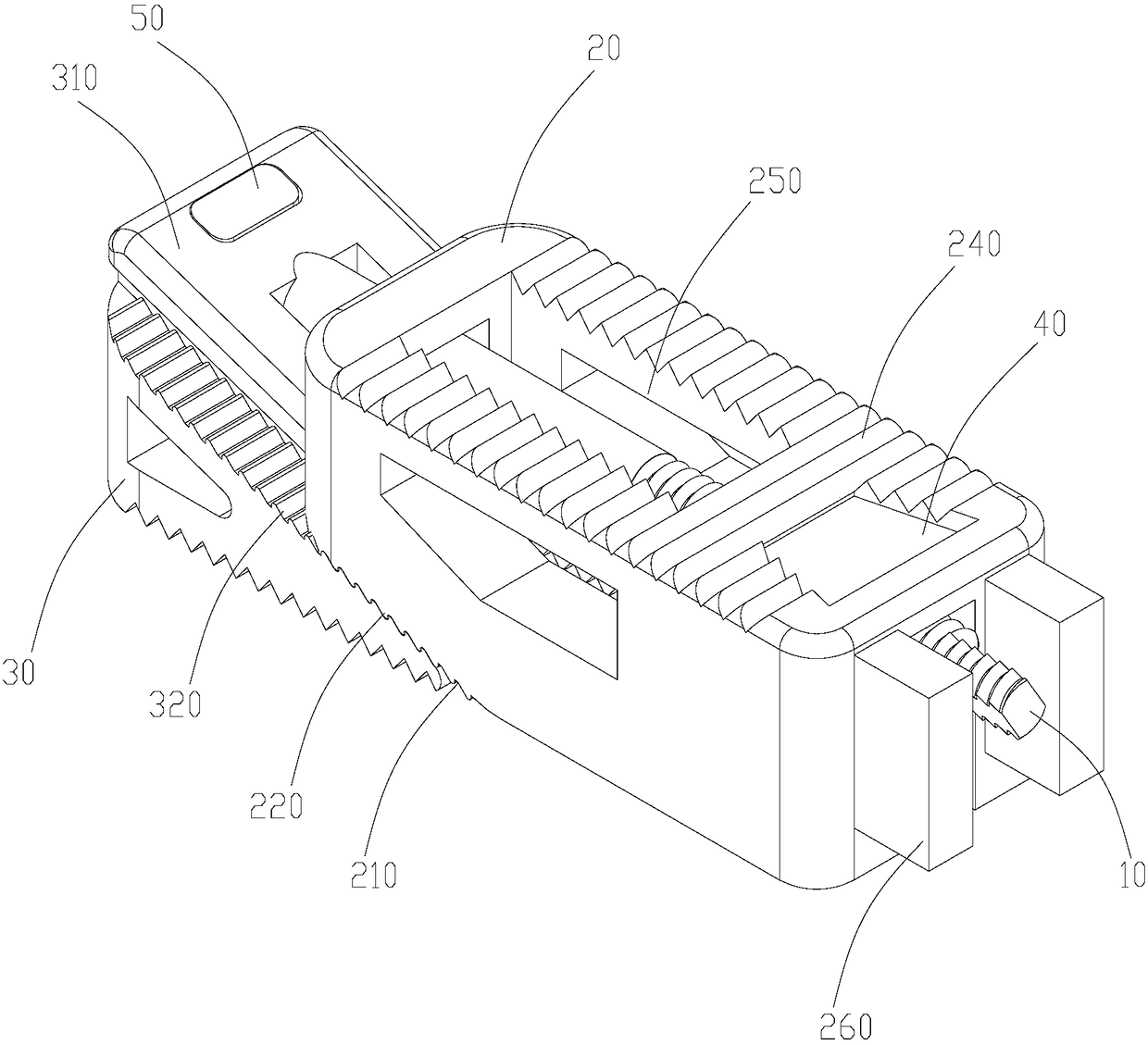

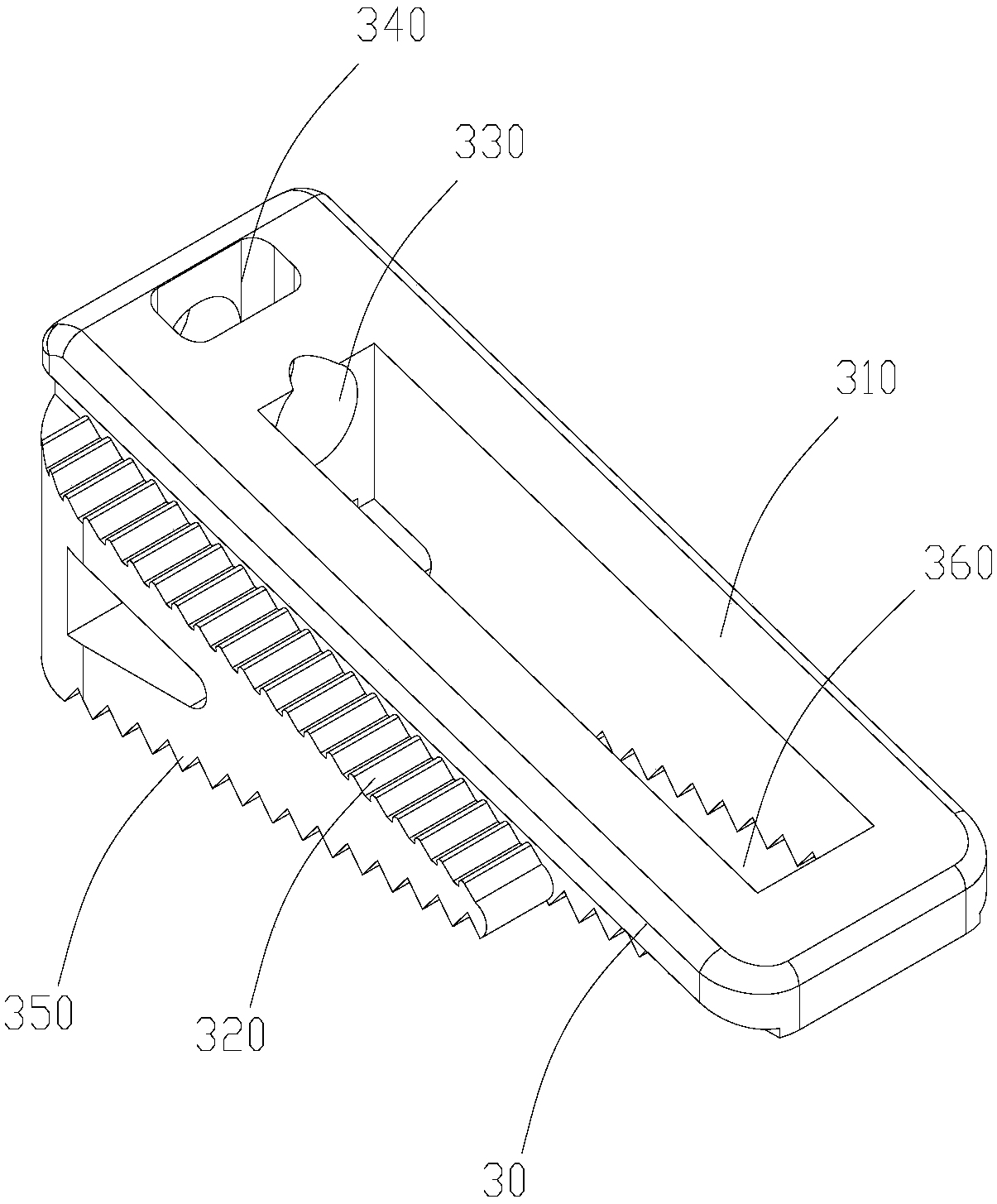

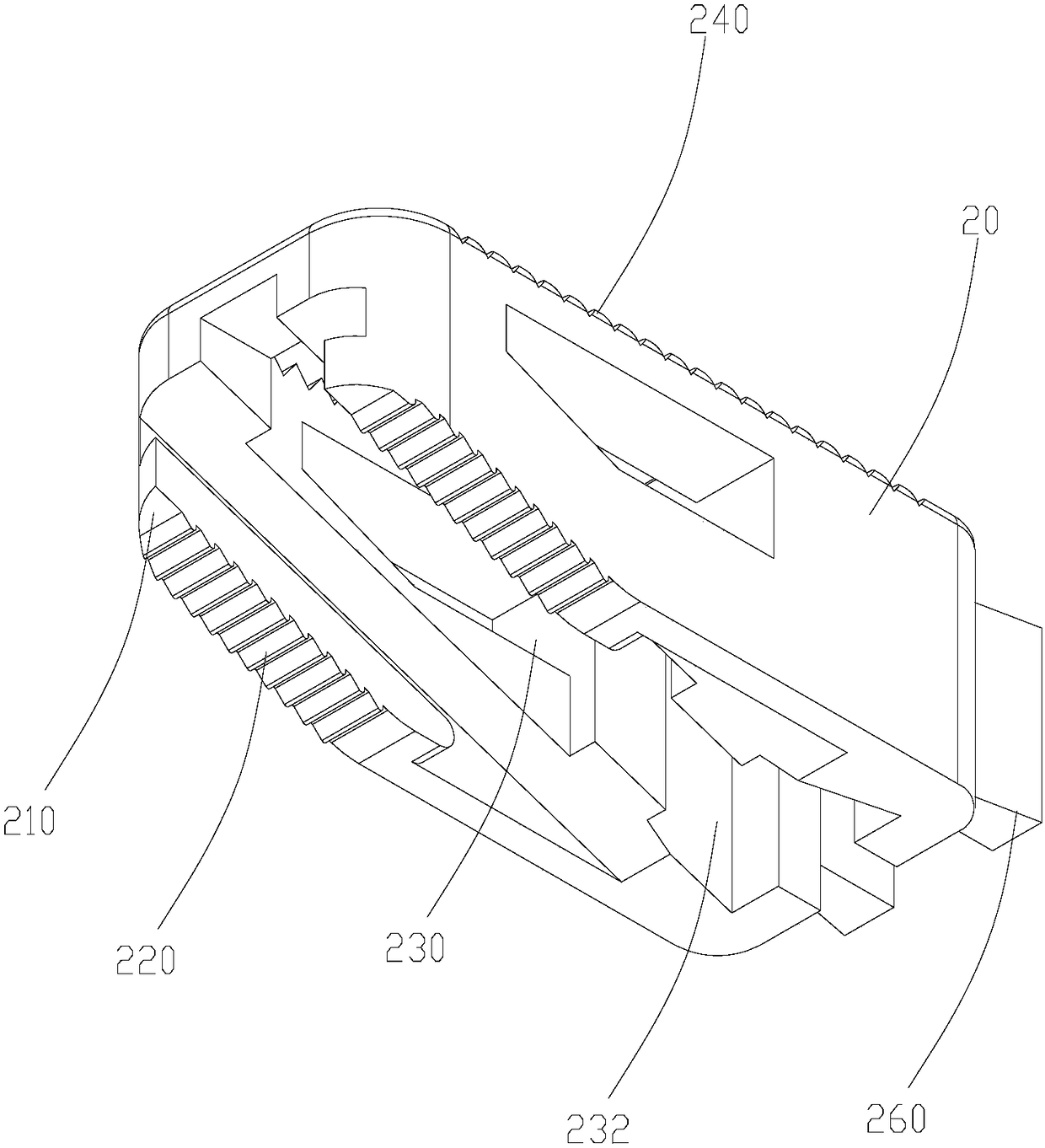

[0030] Such as Figures 1 to 6 As shown, a vertebral body fusion device includes a screw rod 10, an upper plate 20 and a lower plate 30, the upper end surface of the lower plate 30 is a first inclined surface 310, and the lower end surface of the upper plate 20 is provided with a A slope 310 matches the second slope 210, the first slope 310 and the second slope 210 are provided with first anti-slip teeth 220 (320) that can engage with each other, and the lower plate 30 is provided with nuts connected thereto 40 , the nut 40 is sleeved on the screw rod 10 and threadedly connected with the screw rod 10 , the end of the screw rod 10 close to the second slope 210 is limited in the lower plate 30 and is rotatably connected with the lower plate 30 .

[0031] Because the end of the screw rod 10 close to the second slope 210 is limited in the lower plate 30 and is rotatably connected with the lower board 30, by rotating the screw rod 10, the nut 40 threaded with it is driven to move t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap