Electric shock prevention socket

A technology for preventing electric shock and sockets, which is applied in the direction of devices, circuits, and contact parts that prevent contact with live contacts. It can solve the problems of the plug being inserted in place and the protective sheet cannot be pushed away, so as to achieve easy and convenient plugging and unplugging, and avoid electric shock accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

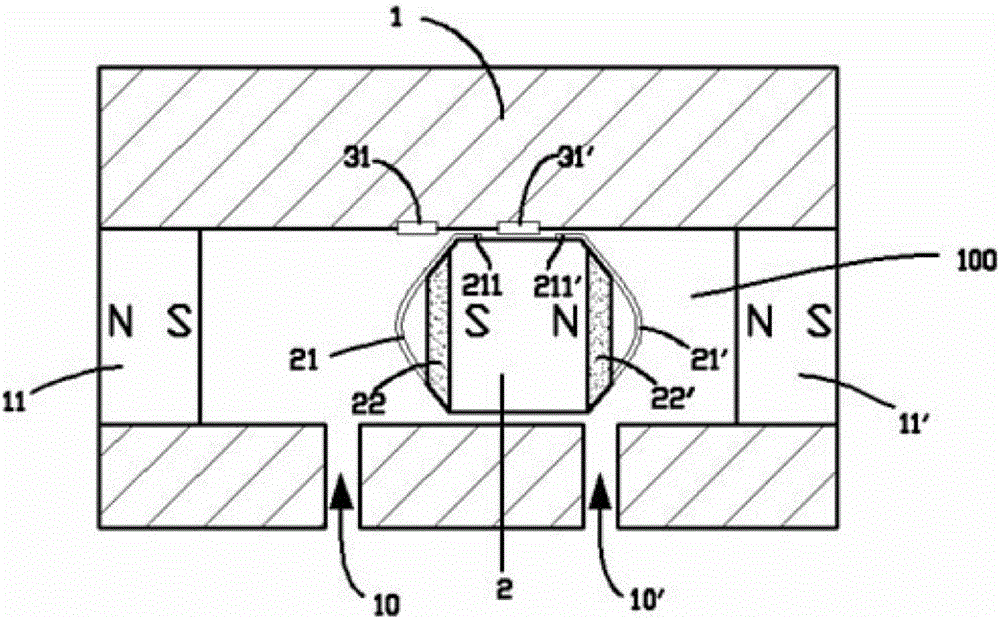

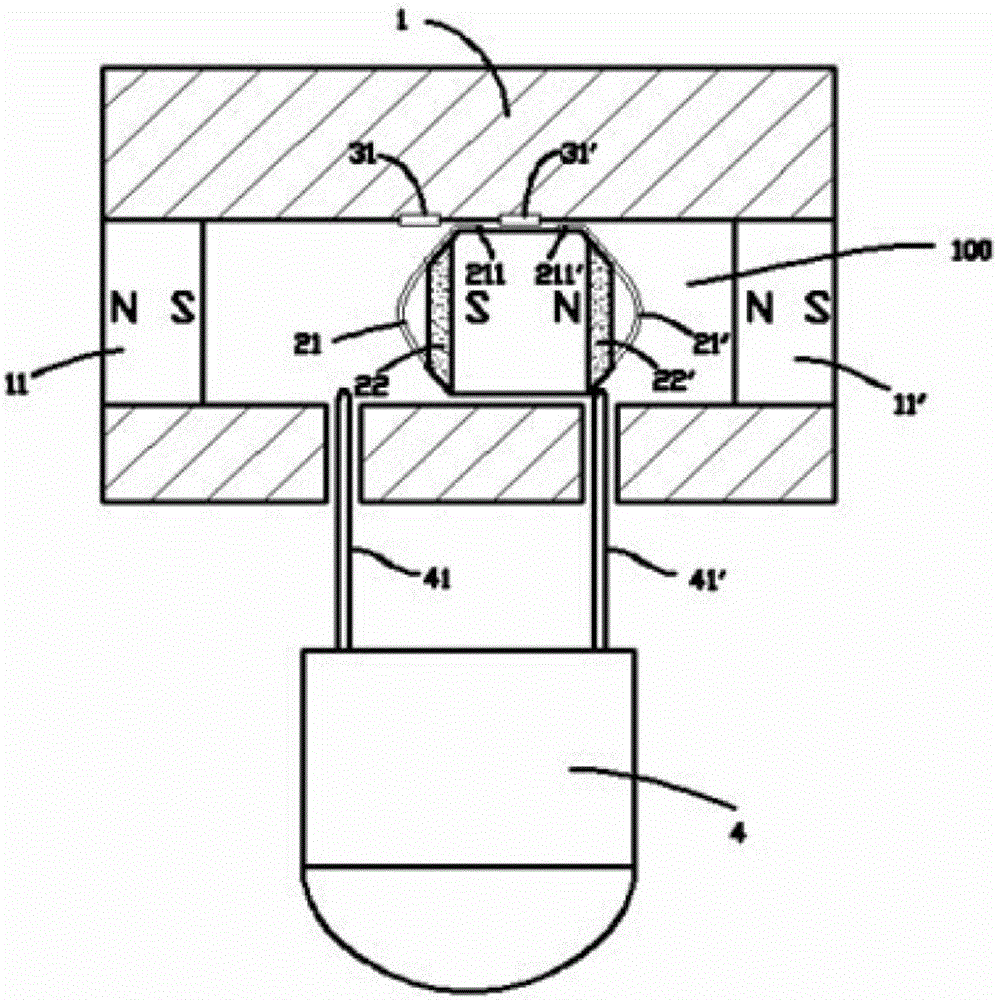

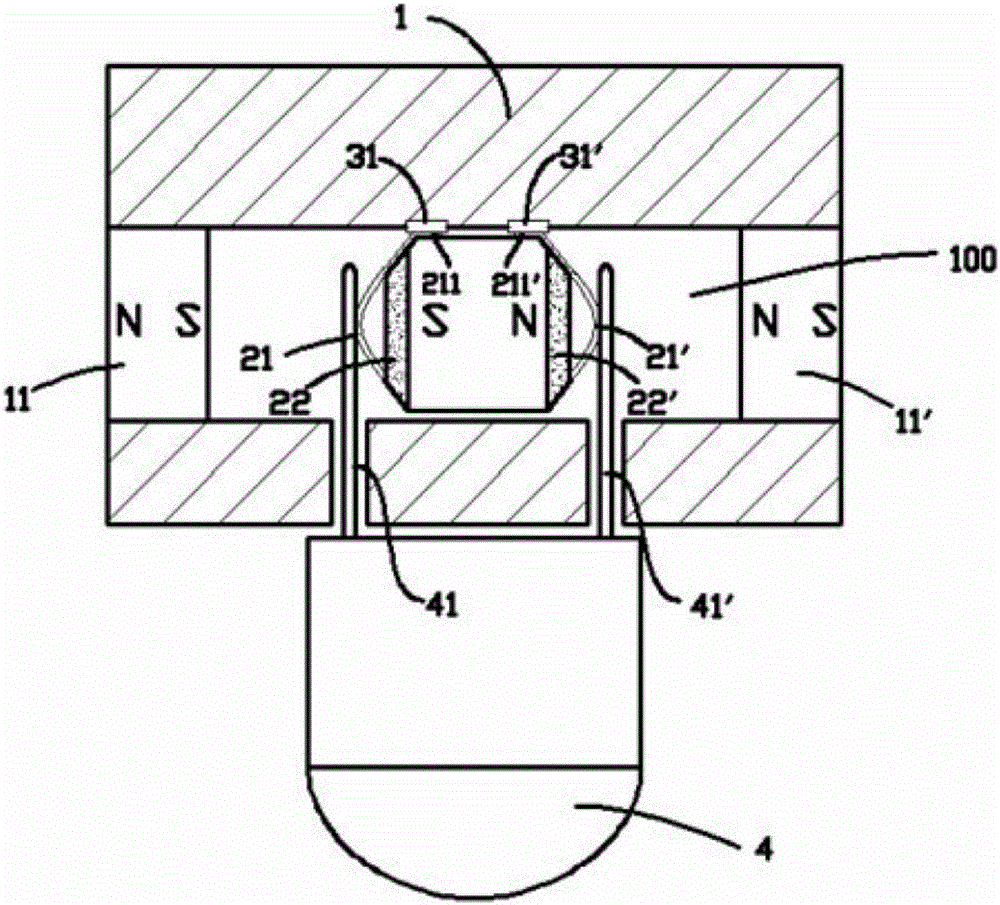

[0014] exist figure 1 In the shown embodiment, the electric shock-proof socket includes a base 1, and two jacks 10, 10' are arranged in front of the base 1; the insertion direction of the jacks 10, 10' is perpendicular to the inside of the base 1 A slideway 100; the slideway 100 is provided with a slider 2; the two ends of the slider 2 are symmetrically composed of metal reeds 21, 21', and the metal reeds 21, 21' are inserted in the face The side of the hole and the insulating parts 22, 22' on the slider body jointly form a slope; wherein, the insulating parts 22, 22' form the root of the slope.

[0015] In this embodiment, the slider 2 is provided with a slider permanent magnet, which forms S poles and N poles at both ends of the slider 2; the two sides of the slideway 100 are provided with opposite poles of the left permanent magnet 11 and the right permanent m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com