A riveting mechanism using leverage to increase force

A lever and riveting technology, applied in relays, electrical components, circuits, etc., can solve the problems of labor, reduction, and unfavorable energy consumption, and achieve the effects of small working space, avoiding rebound, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

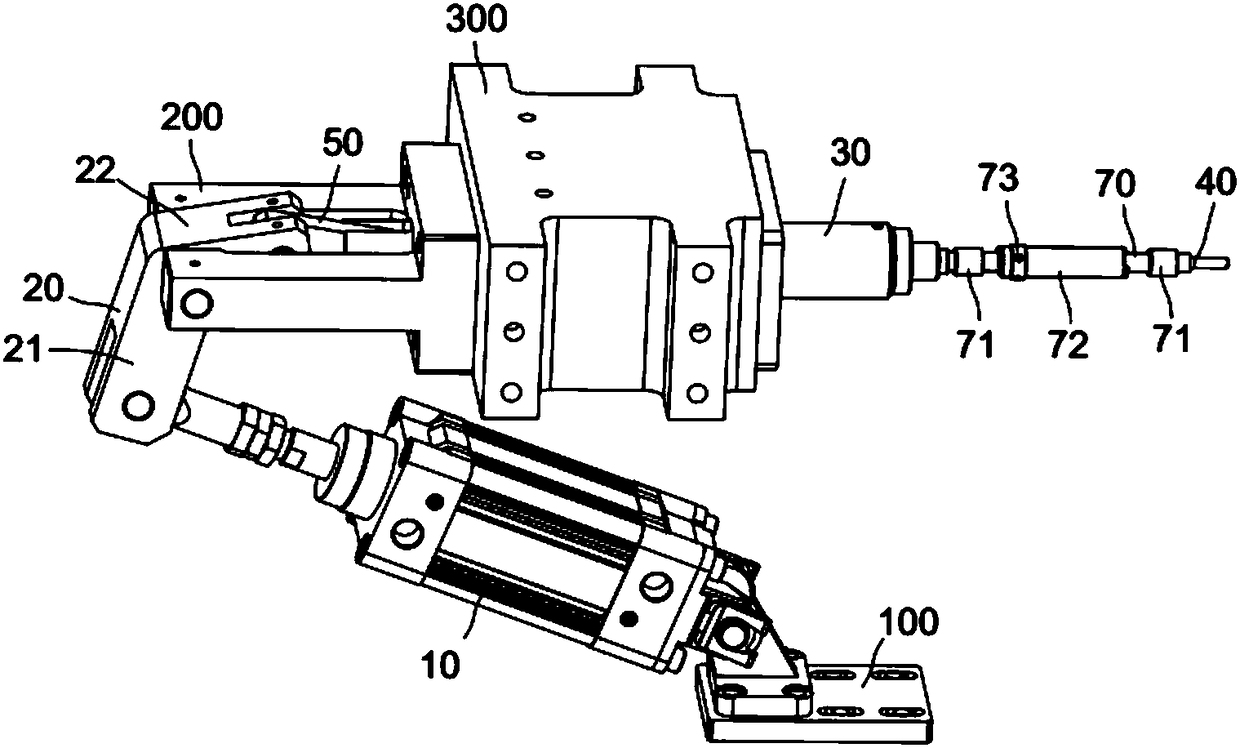

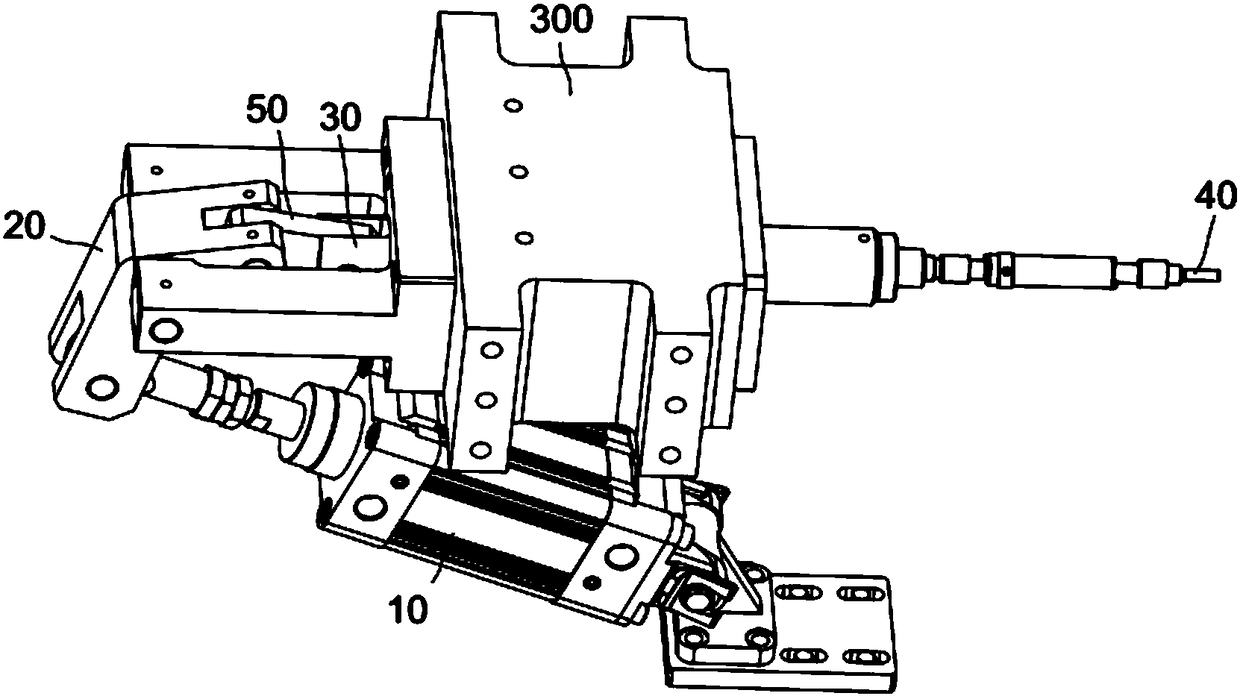

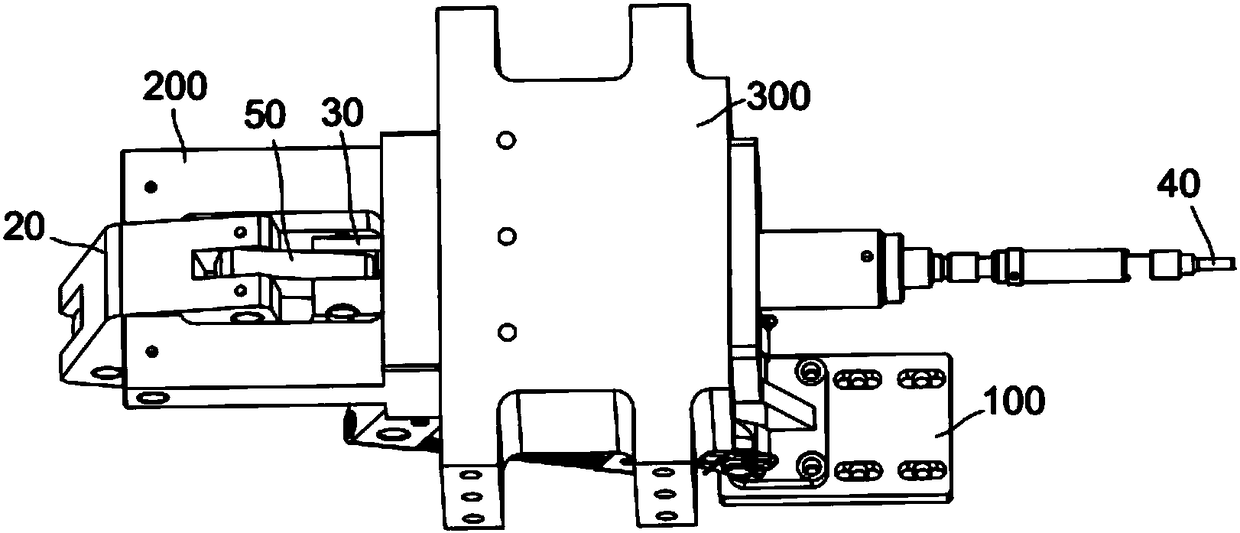

[0023] combine Figure 1 to Figure 3 , a riveting mechanism that uses leverage to increase force, including a push cylinder 10, a lever 20 hinged on a lever seat 200 and one end hinged to the piston rod of the push cylinder, a push rod 30 linked with the lever, and guiding the push rod The push rod guide seat 300 and the riveting head 40 fixedly arranged on the push rod; .

[0024] The cylinder body of the pushing cylinder 10 is hinged on the bottom plate 100 of the pushing cylinder, and the bottom plate of the pushing cylinder is fixedly arranged. The direction the rod is going.

[0025] The lever 20 is V-shaped. The V-shaped lever includes a first straight portion 21 and a second straight portion 22. The hinge of the lever and the lever seat 200 is located at the intersection of the first straight portion and the second straight portion. The piston rod of the cylinder 10 is hinged to the first straight portion, and the connecting rod 50 is hinged to the second straight po...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap