Steam turbine and method for retrofitting multi-stage partial arc steam turbine

A technology for steam turbines and arc segments, which is applied to the support elements of blades, stators, engine elements, etc., and can solve the problems of complex and expensive refurbishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Exemplary embodiments of the present disclosure will now be described with reference to the drawings, in which like reference numerals are used to refer to like elements throughout. In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of the present disclosure. However, the present disclosure may be practiced without these specific details and is not limited to the exemplary embodiments disclosed herein.

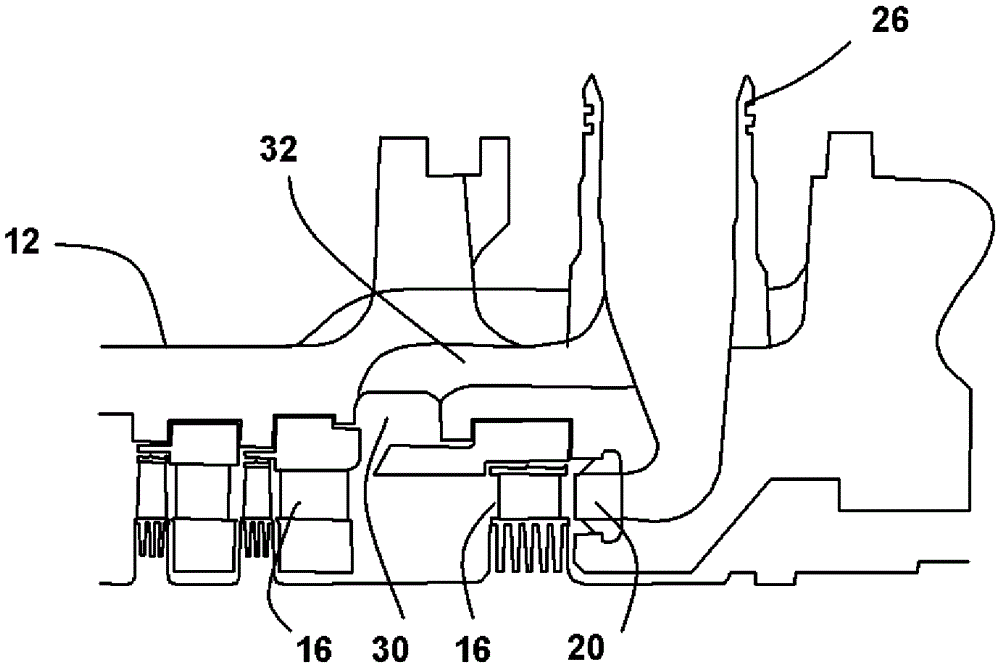

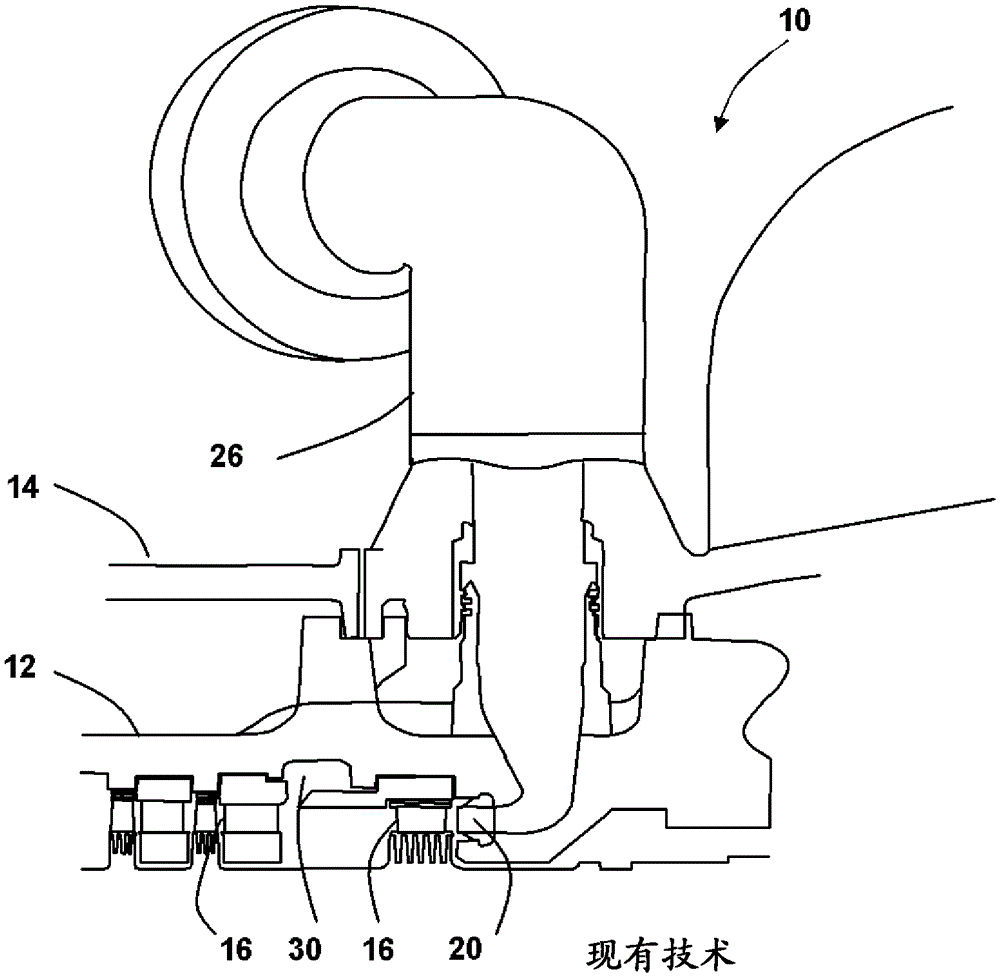

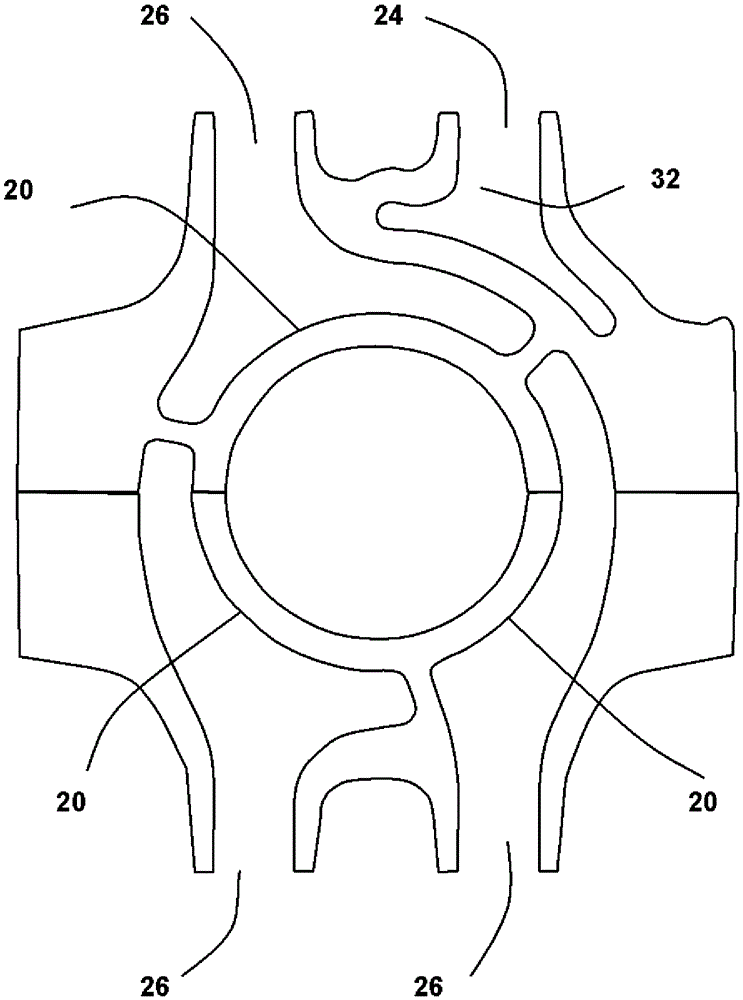

[0016] figure 1 A state-of-the-art multi-stage partial intake arc steam turbine 10 is shown. Steam turbine 10 has an inner casing 12 supporting a plurality of blade rows, including a first blade row 18 , and an outer casing 14 surrounding the inner casing. Steam enters the turbine via a plurality of supply lines 24, 26 each connected to an intake arc segment 20 which feeds the first blade row 18 and which collectively form the main intake air.

[0017] In the exemplary embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com