Damping net tensioner

A technology of tensioning device and damping net, applied in the direction of thin plate connection, connecting member, mechanical equipment, etc., can solve the problems of uncontrollable flow, unadjustable damping net tensioning progress, sealing of rectifier section, etc., and achieves the effect of convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

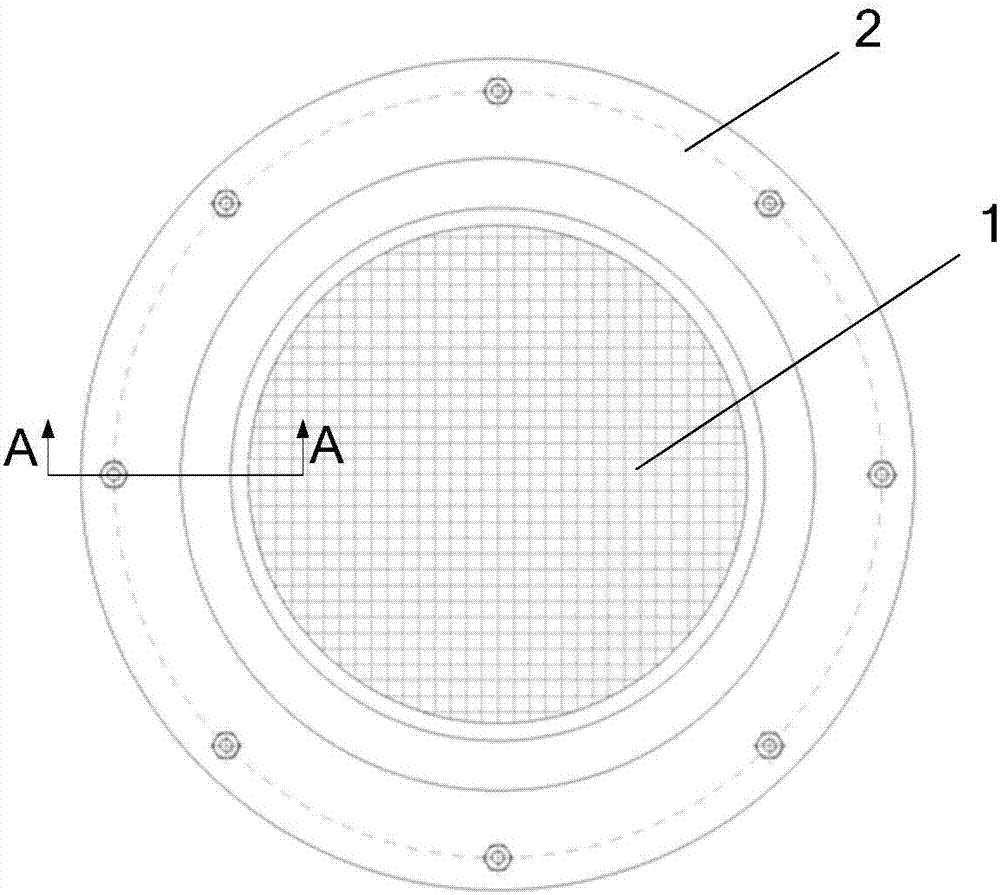

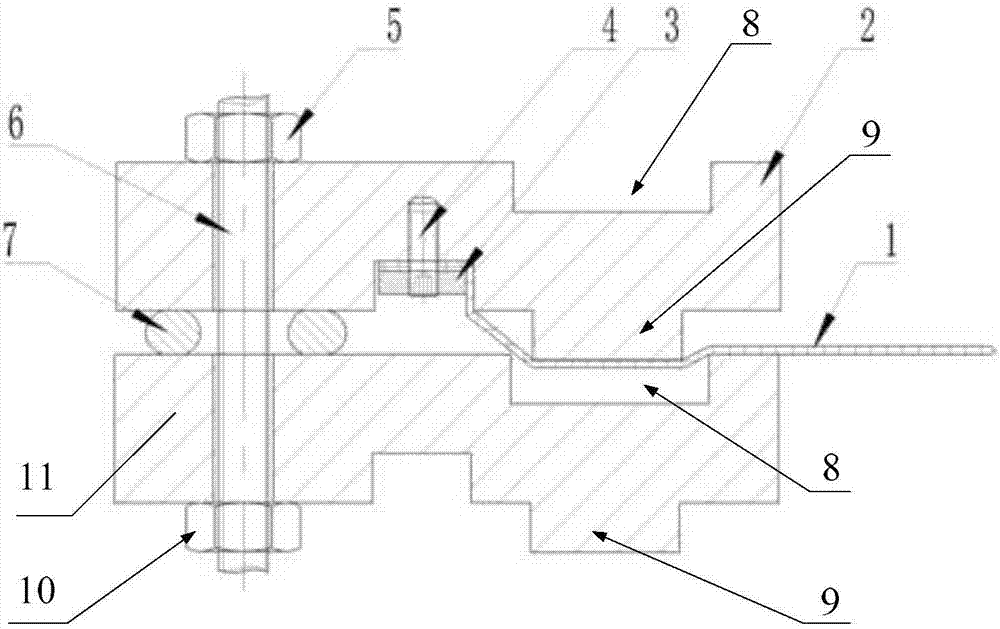

[0026] combine figure 1 and figure 2 As shown, a damping mesh tensioning device provided in Embodiment 1 of the present invention is used to tension and arrange the damping mesh in the flow field area such as the cylinder body, so as to form a rectification effect on the flow field in the area; the device includes The first compression ring 2 and the second compression ring 11 arranged concentrically, the shapes of the first compression ring 2 and the second compression ring 11 are adapted to the cross-sectional shape of the flow field, that is, if the cylinder is a cylinder Shaped channel, then the first compression ring 2 and the second compression ring 11 are circular rings; the opposite side of the first compression ring 2 and the second compression ring 11 extends circumferentially with an annular protrusion 9, and the second compression ring 2 The side of the compression ring 11 opposite to the first compression ring 2 is circumferentially extended with an annular groo...

Embodiment 2

[0033] A damping net tensioning device provided in Embodiment 2 differs from Embodiment 1 in that:

[0034] The clamping structure includes bolts, and the screw rod 6 is axially passed through the first compression ring 2 and the second compression ring 11; Side; a third nut is installed on the bolt and on the side of the second compression ring 11 opposite to the first compression ring 2 .

[0035]It can be seen that in this embodiment, the screw rod 6 and the first nut 5 in the first embodiment are integrated into one bolt, because in order to realize the adjustment of the clamping force between the first compression ring 2 and the second compression ring 11, only the One nut can be adjusted, and the other nut can be fixed, which is equivalent to a bolt structure, thereby simplifying the structure and making the installation operation more convenient.

[0036] The difference between the second embodiment and the first embodiment is only that the screw rod 6 and the first nu...

Embodiment 3

[0038] The damping net tensioning device provided in Embodiment 3 belongs to the same general inventive concept as Embodiment 1 and Embodiment 2, specifically:

[0039] It includes a plurality of third compression rings arranged concentrically, one side of the third compression ring is circumferentially extended with an annular protrusion 9, and the other side of the third compression ring is corresponding to the annular protrusion 9 An annular groove 8 is extended circumferentially at the position of the third compression ring, so that the annular protrusion 9 and the annular groove 8 on two adjacent third compression rings form a mutual insertion relationship; On one side or the other side, and on the outer side of the annular protrusion 9 and the annular groove 8, a fixed structure is provided, and the fixed structure is used to fix the edge of the tensioned net 1; between every two adjacent third compression rings Elastic members 7 are evenly spaced between them, and a cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com