Drying box body

A technology for ovens and cabinets, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc., which can solve the problems of excess heat in the oven, waste of electric energy, and high ambient temperature, and achieve convenient and clean oven structure, energy saving, and simple oven structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

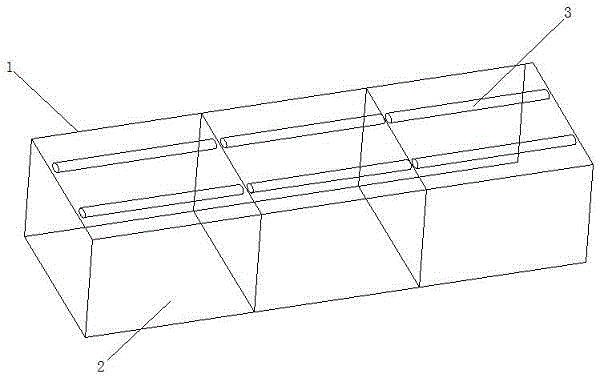

[0007] see figure 1 , the specific embodiment adopts the following technical scheme: the oven 1 is divided into adjustable three-section heating zones 2 at both ends and in the middle, and each heating zone 2 is independently installed with two infrared lamp tubes 3, so that it can be processed according to the product situation. Segmented heating, the structure of the oven is simple, easy to clean, no need for hot air circulation, effectively reducing the problem of black spots and impurities caused by circulating air, and the distance between the infrared lamp and the product is reduced to 5cm, which greatly reduces the temperature of the infrared lamp in the oven. Quantity, effectively save energy, energy saving and environmental protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com