A flipping device for a movable stand seat

A technology of flipping device and movable stand, which can be applied to chairs, chairs in theaters, auditoriums or similar places, and household appliances, etc., can solve the problems of complicated maintenance operation and high cost, and achieve the effect of convenient operation and fast unfolding and folding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

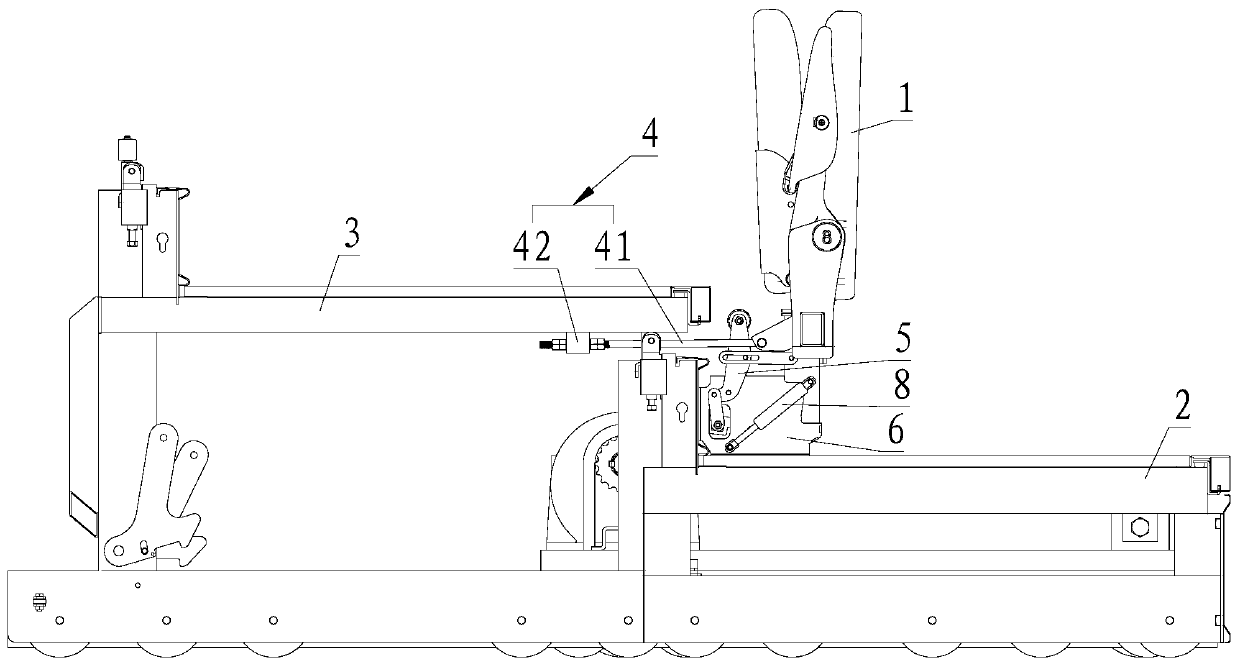

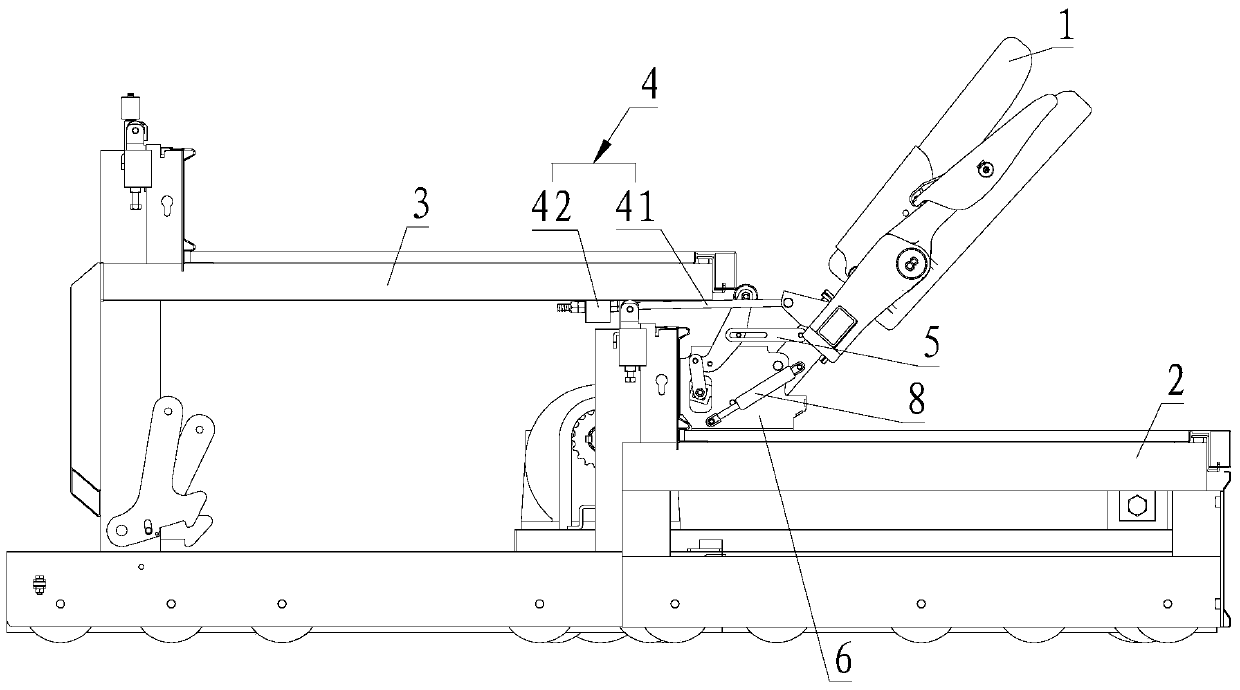

[0046] Please refer to Figure 1 to Figure 11 , Embodiment 1 of the present invention is:

[0047] A flipping device for a movable stand seat, comprising a pull rod mechanism 4 and a locking mechanism 5, one end of the pull rod mechanism 4 is slidably connected to the peripheral rear seat platform 3, and the other end is rotatably connected to the peripheral front row seat 1 , the locking mechanism 5 is located between the front seat 1 and the rear seat platform 3, the lower end of the locking mechanism 5 is frictionally connected with the bottom of the front seat 1, and the locking mechanism 5 The upper end of the position mechanism 5 is located on the sliding track of the rear seat platform 3;

[0048] The pull rod mechanism 4 includes a pull rod 41 and a slider 42, the slider 42 is provided with a first waist-shaped hole 4241 placed up and down, the right end of the pull rod 41 is rotationally connected with the front seat 1, and the pull rod The left end of 41 is passed ...

Embodiment 2

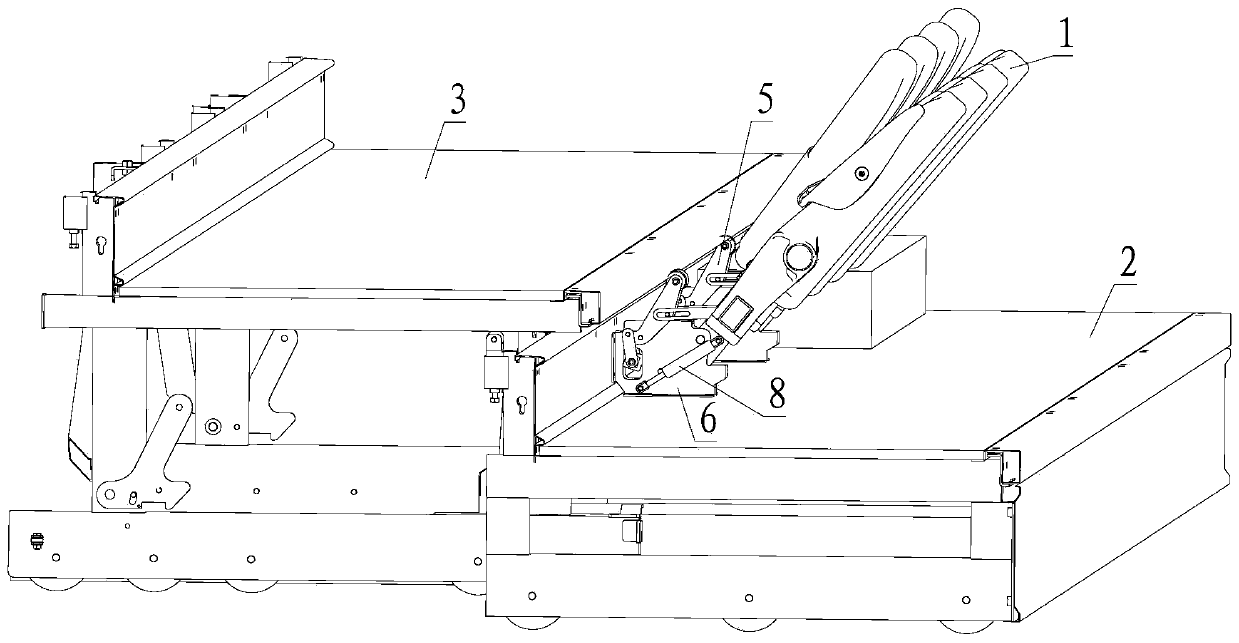

[0050] Please refer to Figure 1 to Figure 11 , the second embodiment of the present invention is:

[0051] A flipping device for a movable stand seat. On the basis of the first embodiment, the left end of the first connecting rod 51 is provided with a second waist-shaped hole 511, and the side of the second connecting rod 52 is protrudingly provided with a third A rotating shaft 521, the third rotating shaft 521 is slidingly and rotationally matched with the second waist-shaped hole 511;

[0052] The rear seat platform 3 is provided with a profile assembly 31, and the profile assembly 31 includes an inverted U-shaped upper profile 311, a U-shaped lower profile 312 and side connecting plates 313, and the inverted U-shaped upper profile 311 is connected to the U-shaped upper profile. The width of the lower profile 312 is the same, and a gap 314 is provided between the opposite side walls. The side connecting plate 313 is located at the end of the profile assembly 31, and is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com