Folding full-motion horizontal tail mechanism

A folding and flat tail technology, applied in the field of folding wings, can solve the problems of late start of research and complex technology, and achieve the effects of rapid deployment, simplified action mechanism, and firm locking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

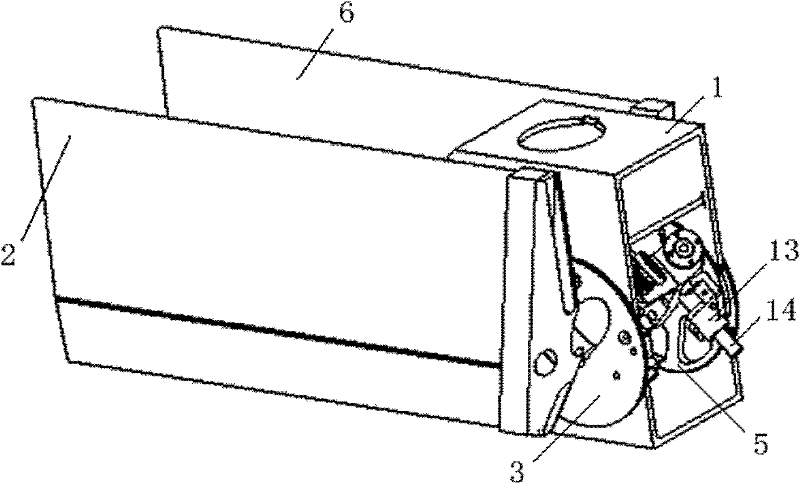

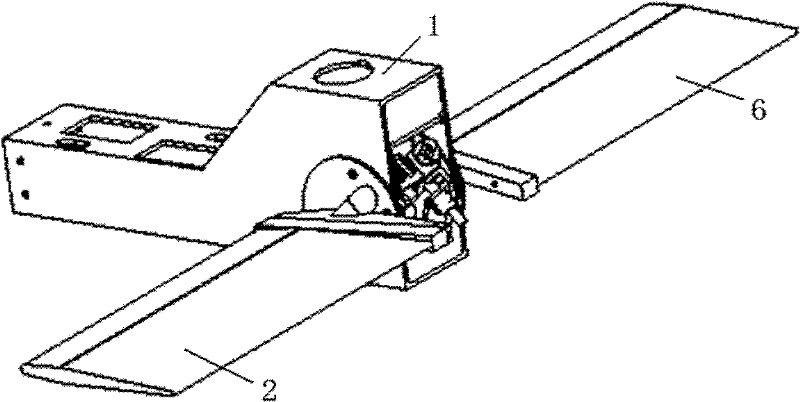

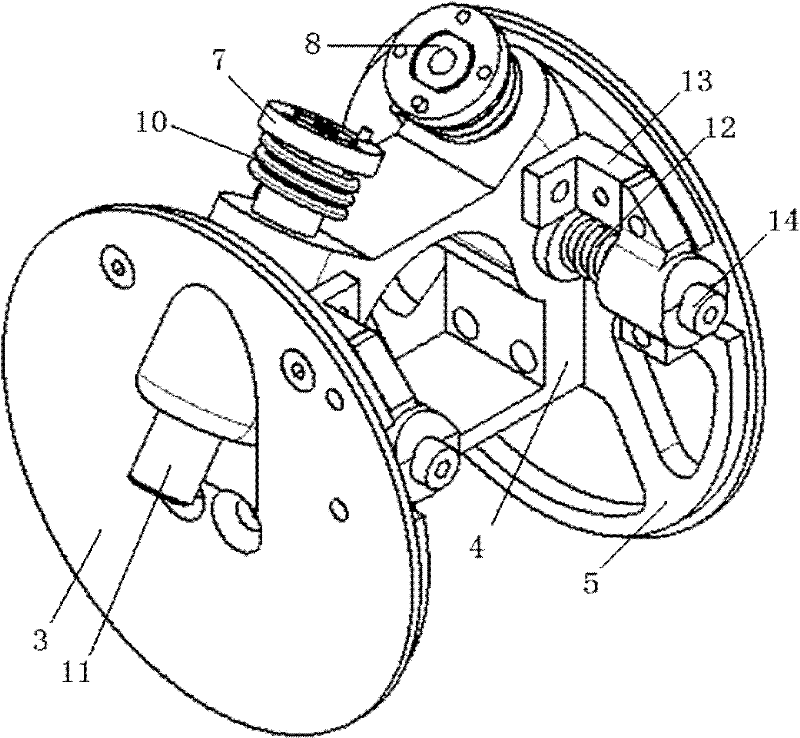

[0018] The folding full-motion horizontal tail mechanism of the present invention comprises a fuselage 1, a left horizontal tail 2, a left turntable 3, a flat tail connector 4, a right turntable 5, a right flat tail 6, a torsion spring cover 7, a pressure screw 8, and a torsion spring 10 , flat tail rotating shaft 11 and locking mechanism, wherein, as attached Figure 4 , the flat tail connecting body 4 is processed with two left and right symmetrical rotating shaft installation holes, the angle between the axis of the mounting hole and the horizontal plane is 55.5°, and the flat tail connecting body 4 is also processed with a locking pin hole and the flat tail rotating shaft 11 mounting holes run through; Locking mechanism comprises compression spring 12, locking pin seat 13 and locking pin 14; Figure 5 and 6 As shown, the left horizontal tail 2 and the right hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com