Light six-axis universal robot with extending arm provided with execution terminal

A technology for performing end and extending arms, applied in the field of robotics, can solve problems such as difficulty in meeting actual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

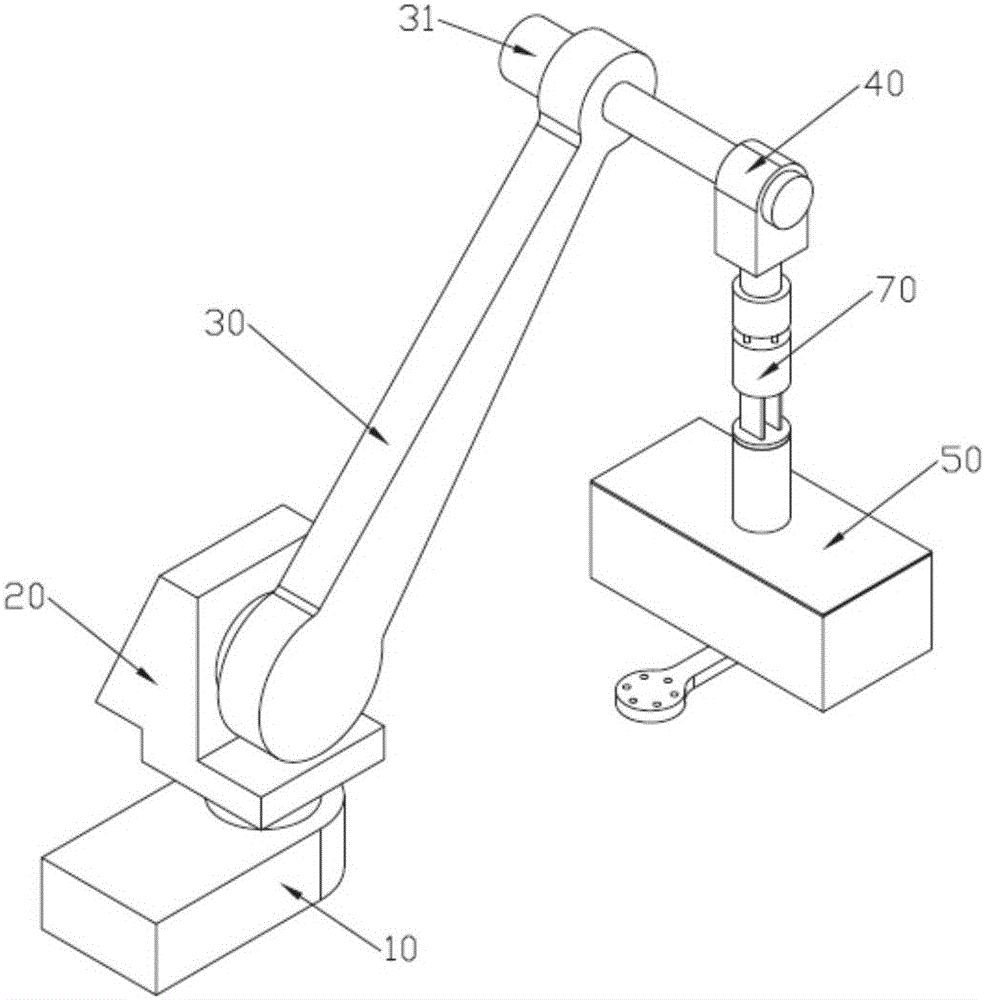

[0034] Such as figure 1 As shown, a light-duty six-axis universal robot with an execution end on an extension arm includes a base body 10, a waist swivel part 20 pivotally connected to the base body 10, a big arm 30 pivotally connected to the waist swivel part 20, The forearm 40 fixed on the output shaft of the sixth motor 31 at one end of the boom 30, the waist swivel part 20 rotates around the base body 10, and the big arm 30 rotates around the waist swivel part 20;

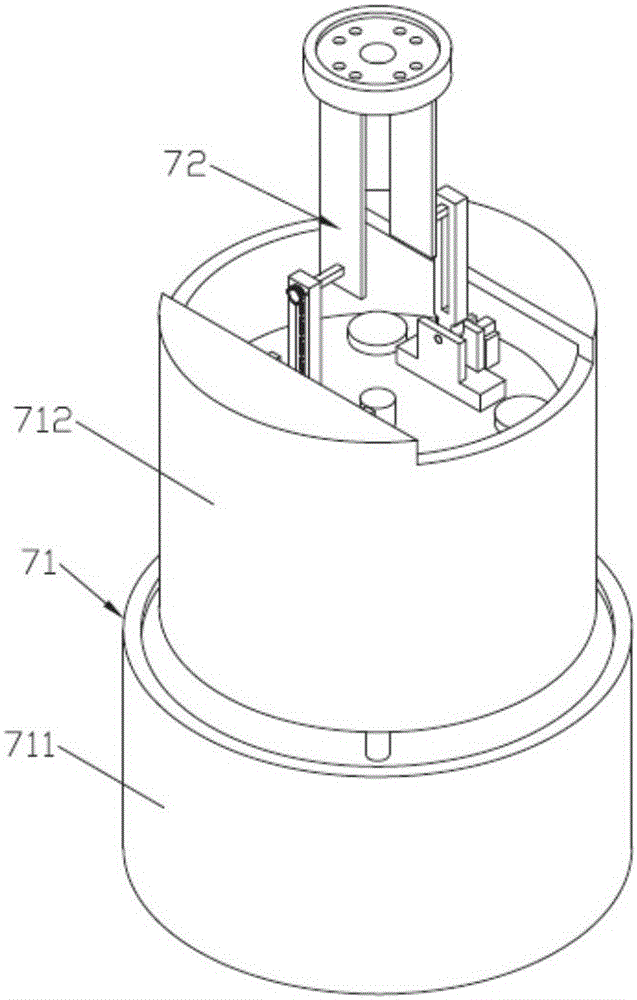

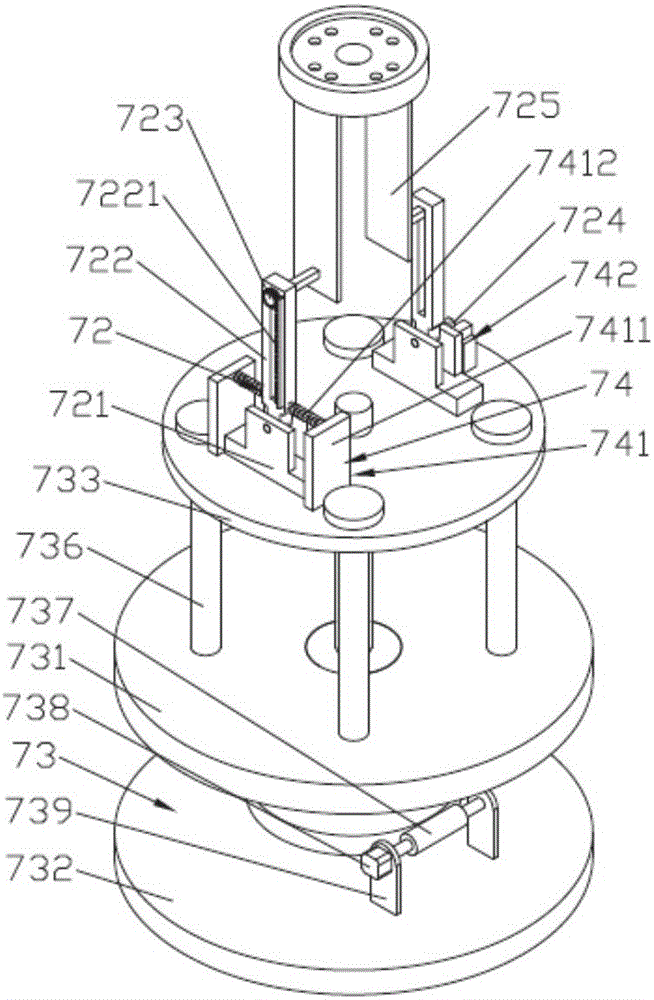

[0035] Such as Figure 1 ~ Figure 4 As shown, the forearm is provided with an extension arm 70, and the extension arm includes a support body 61 fixedly connected to the forearm, a first telescopic mechanism 73 installed on the support body, and a swing mechanism hinged on the first telescopic mechanism. 72. Slide the second telescopic mechanism arranged in the sliding groove of the swing mechanism 72 and the reset device 74 installed on the swing mechanism 72;

[0036] Such as Figure 1 to Figure 8 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com