A kind of bamboo weaving flower basket weaving method

A flower basket and bamboo weaving technology, which is applied in the field of weaving bamboo flower baskets, can solve the problems affecting the appreciation and artistry of woven products, the appearance of woven products is not full enough, and it is not suitable for batch weaving, etc., so as to achieve better appreciation, improved appreciation and artistry, knitting easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

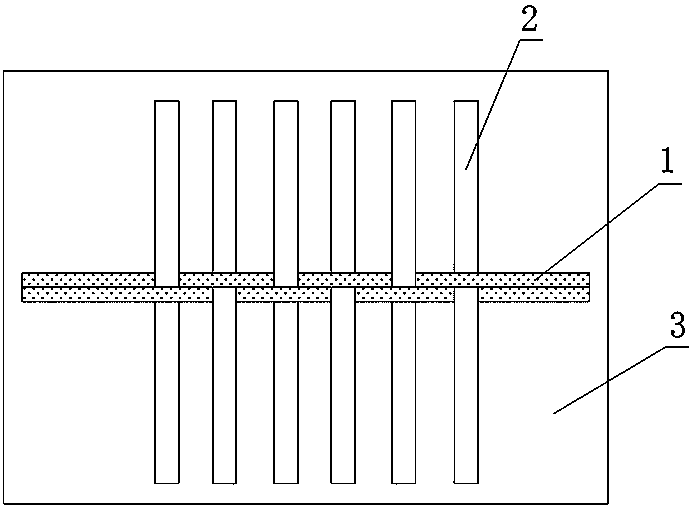

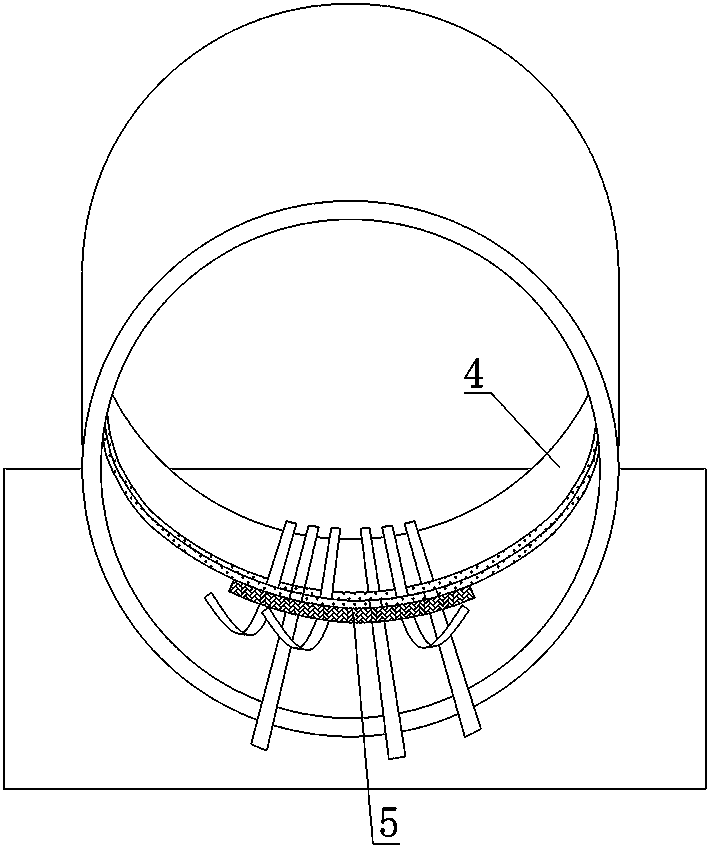

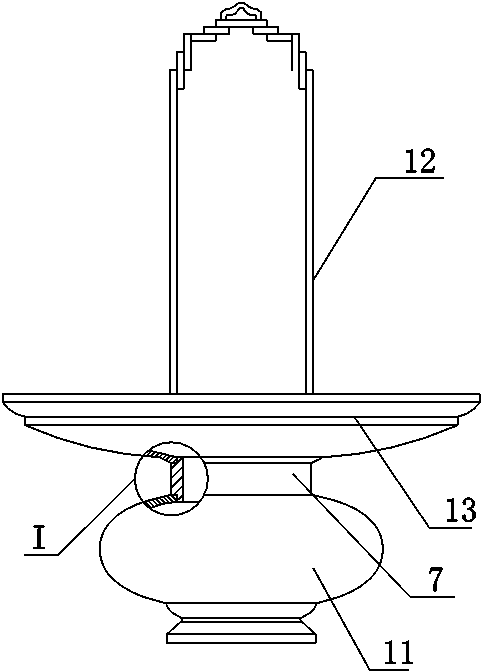

[0025] Such as Figure 1~Figure 2 As shown, a bamboo weaving flower basket weaving method, which includes a weaving process and an assembly process, the weaving process includes a base weaving process, a support cylinder weaving process and a faceplate weaving process, and the support cylinder weaving process includes the following step,

[0026] S1, start the braiding head, measure the circumference of the inner circle side wall section of the cylinder mold 4, then according to the interval width between the warp strips 2 and the circumference of the inner circle side wall section of the cylinder mold 4 according to the technical requirements, The number of warp strips 2 required for weaving products can be roughly determined, and a part of the warp strips 2 and two weft strips 1 are placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com