Sensor fixing device

A fixed device and sensor technology, applied in the field of sensors, can solve problems such as inappropriate signal detection, and achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

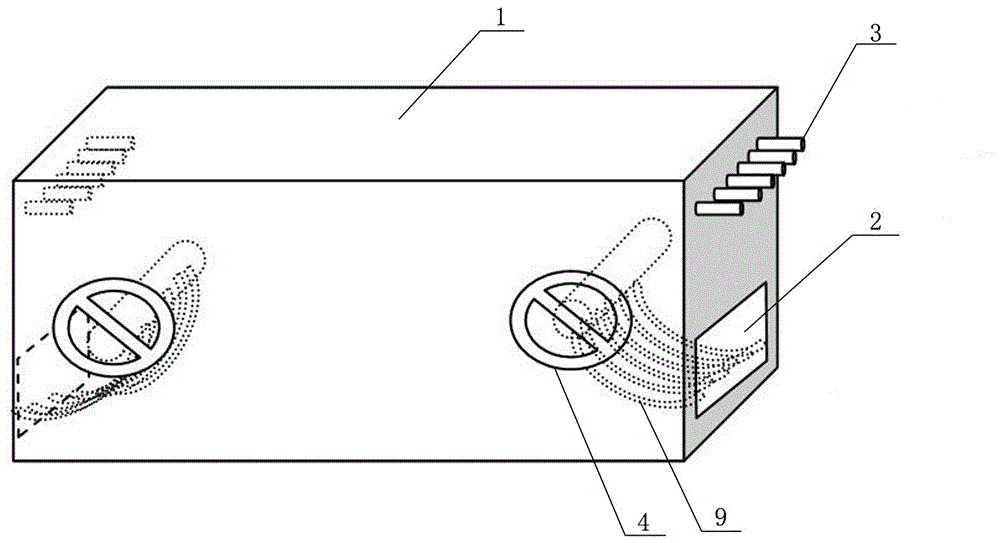

[0018] A sensor fixing device, including a fixing module 1, the structure of the left and right sides of the fixing module 1 is symmetrical, such as figure 1 shown.

[0019] Now take the structure of one side of the fixed module as an example for illustration.

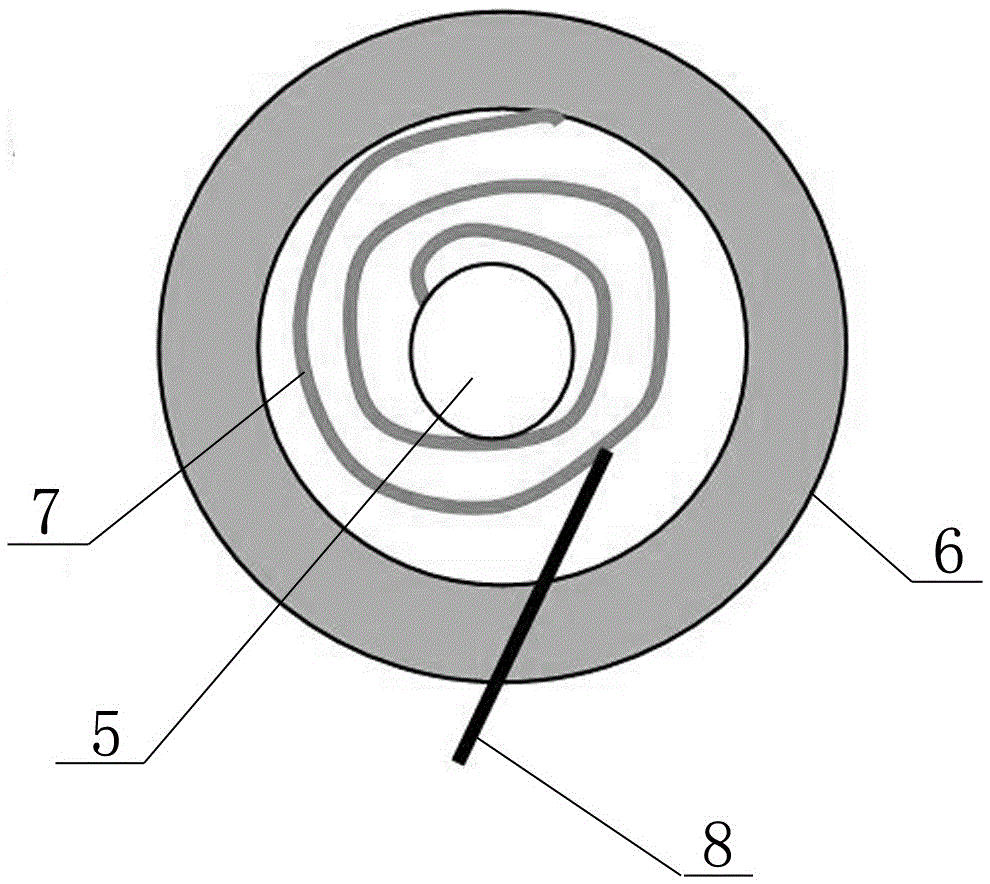

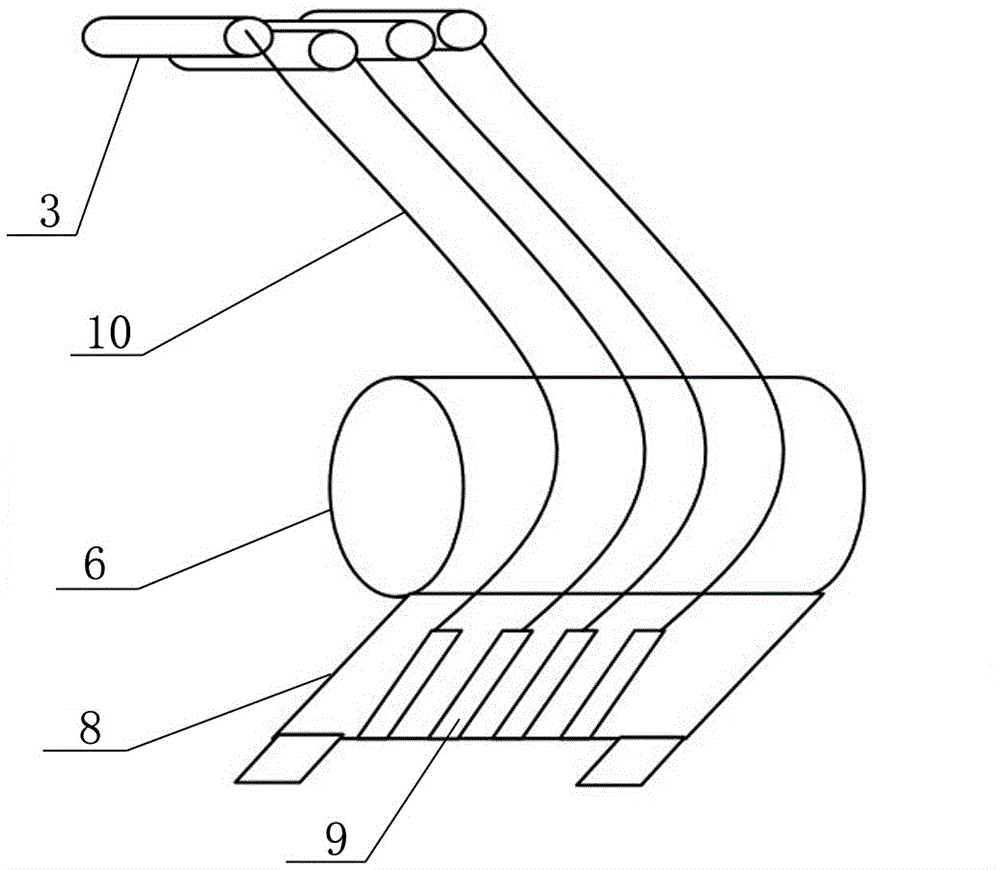

[0020] A sensor installation cavity 2 is provided on one side of the fixed module 1, and an outer ring sleeve 6 is fixedly arranged in the sensor installation cavity 2, such as figure 2 As shown, the center of the outer ring sleeve 6 is fixedly installed with a rotating shaft 5, and a rotating handle 4 is installed at one end of the rotating shaft 5; It is fixedly connected, and its outer end is against the inner wall of the outer ring sleeve 6; the outer ring sleeve 6 is provided with a through groove for the plastic card 8 to pass through, and the plastic card 8 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com