A kind of non-aqueous electrolytic solution and lithium ion battery containing the non-aqueous electrolytic solution

A non-aqueous electrolyte and non-aqueous solvent technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of limited battery performance improvement, and achieve the products with wide electrochemical window, inhibited reaction, and excellent water removal ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the non-aqueous electrolyte provided by the present invention is a common method used by those skilled in the art, that is, to mix all components (including lithium salt, non-aqueous solvent and additives) uniformly, and the present invention is not particularly limited.

[0024] The present invention also provides a lithium-ion battery, including a casing, an electric core contained in the casing, and a non-aqueous electrolyte. The electric core includes a positive electrode, a negative electrode, and a separator between the positive electrode and the negative electrode, wherein the non-aqueous electrolyte The aqueous electrolyte is the non-aqueous electrolyte provided by the present invention. Compared with non-aqueous electrolytes using other common additives in the prior art, the non-aqueous electrolyte obtained by adding the specific additives in the same amount in the present invention can greatly improve the high-temperature performance o...

Embodiment 1

[0028] (1) Preparation of non-aqueous electrolyte

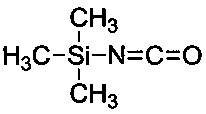

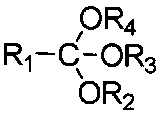

[0029] Mix ethylene carbonate (EC), diethyl carbonate (DEC), trimethylsilyl isocyanate (TMSIT), and triethyl orthoacetate (TEOA) at a mass ratio of 30:50:5:15 in the mixed solvent , adding the solute LiPF 6 , to make a non-aqueous electrolyte with a lithium salt content of 1.0 mol / L, denoted as S1.

[0030] (2) Preparation of Li-ion battery

[0031] LiCoO 2 , Conductive materials such as acetylene black, binder PVDF at a ratio of 85:10:5 and appropriate amount of NMP (N-methylpyrrolidone) are stirred into a slurry, which is smeared on a 20 μm thick aluminum foil, dried and pressed to obtain a positive electrode sheet, The positive electrode piece is obtained after spot welding the tabs.

[0032] Mix graphite (type P15B) with SBR and CMC at a weight ratio of 100:3:2, and use deionized water as a solvent to obtain anode material paste. Apply it on a 12 μm thick copper foil, dry it, press it to obtain a negative electrode s...

Embodiment 2-7

[0035]Non-aqueous electrolytes S2-S7 and lithium-ion batteries S20-S70 were prepared in the same steps as in Example 1, the difference being that in step (1), trimethylsilyl isocyanate (TMSIT), orthoacetic acid The ratio of triethyl ester (TEOA) is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com