Hybrid Excitation Permanent Magnet Motor with Dual Field Windings

A double-excitation winding and hybrid excitation technology is applied to synchronous motors, synchronous machines, and electrical components with stationary armatures and rotating magnets to achieve high power density and operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

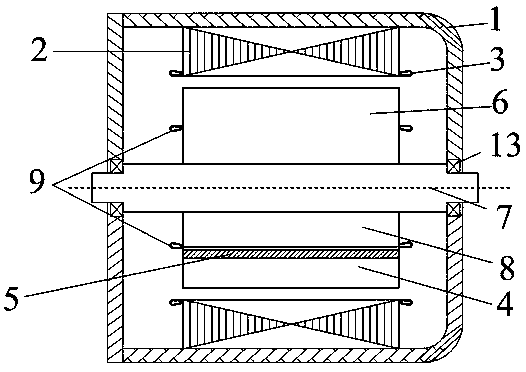

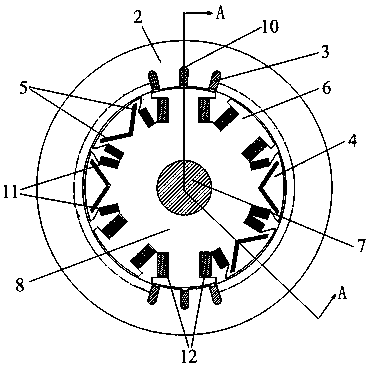

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

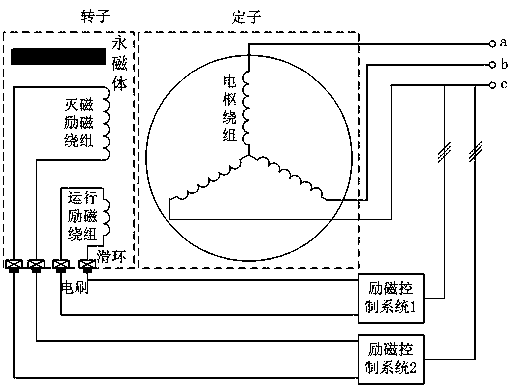

[0021] Depend on Figure 1-3 It can be seen that the hybrid excitation permanent magnet motor with double excitation windings of the present invention includes a casing 1, a stator core 2 is arranged in the casing 1, a slot 10 is slotted along the circumferential direction on the stator core 2, and a stator is arranged in the slot 10. armature winding 3. The casing 1 and the stator core 2 are fixed. A rotating shaft 7 is disposed inside the casing 1 , and the rotating shaft 7 is connected to the casing 1 through a bearing 13 . A rotor core 8 is arranged on the rotating shaft 7. There are permanent magnet poles 4 and ferromagnetic poles 6 on the rotor core 8. The rotor winding 9 consists of a rotor de-excitation excitation winding 11 and a rotor running excitation winding 12. The permanent magnet 5 and the rotor de-excitation excita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com