Anti-dislocation structure for water delivery tunnel crossing large-scale movable fault zone

A technology for water delivery tunnels and fault zones, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as poor adaptability, and achieve the effect of ensuring the quality of water delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

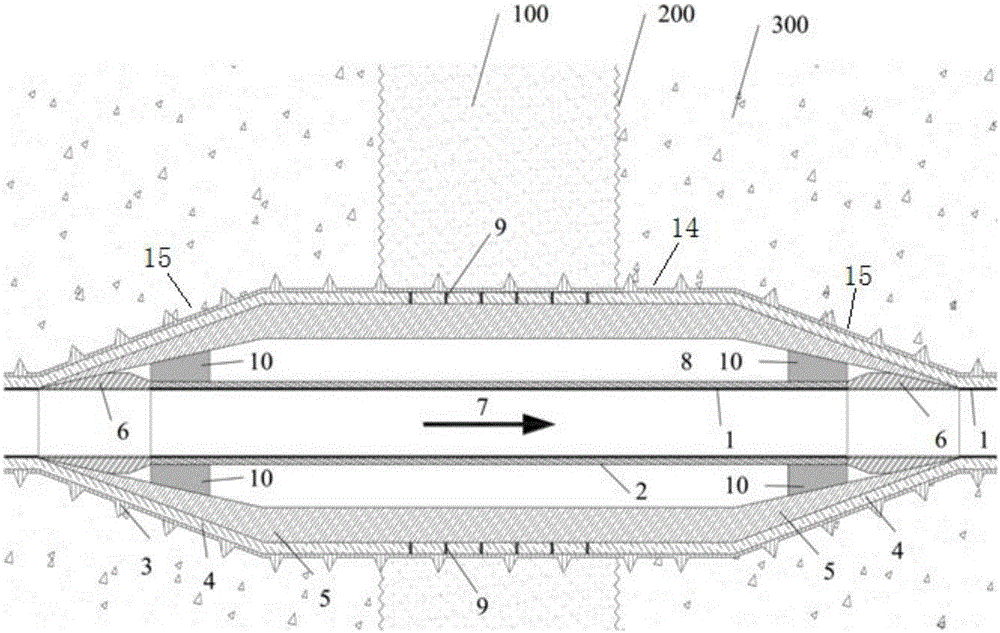

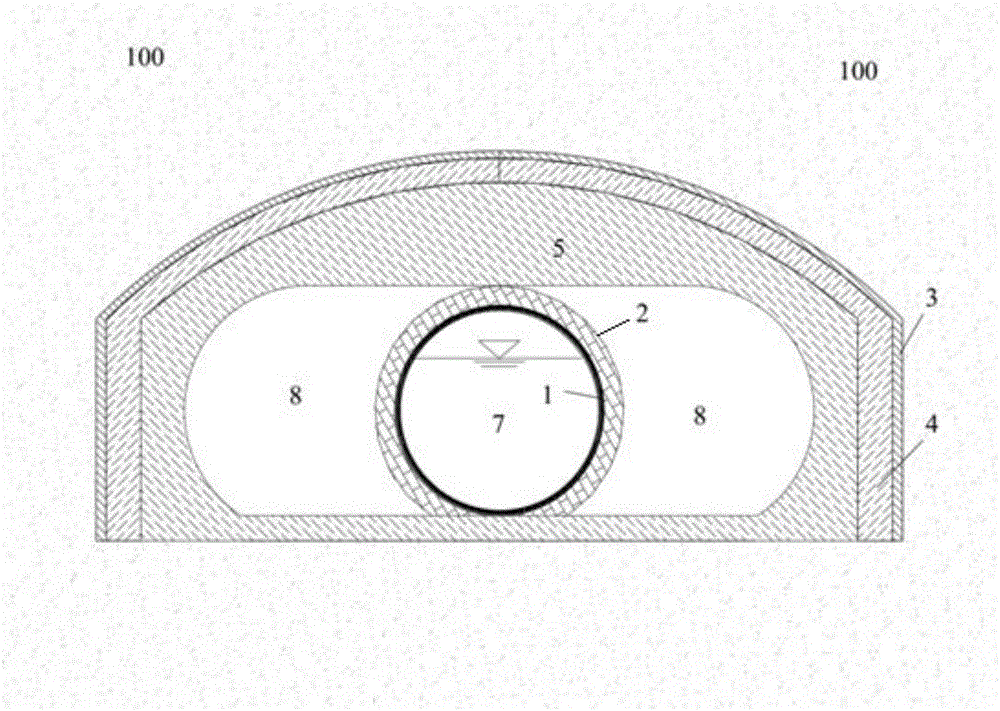

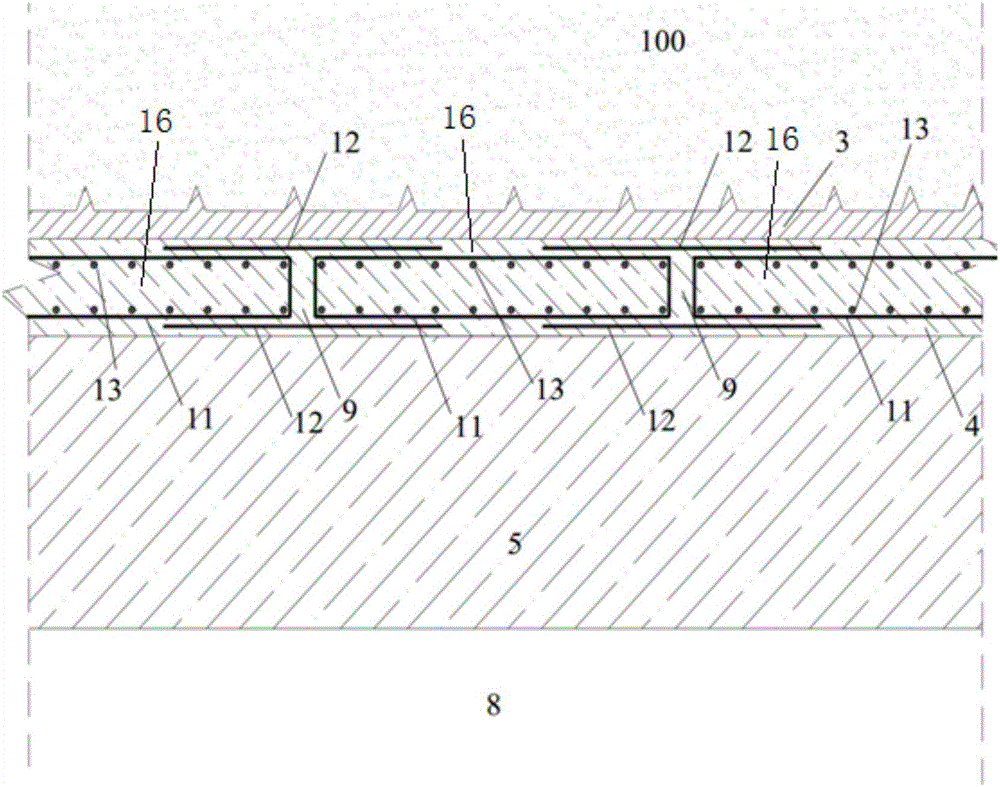

[0023] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0024] A dislocation-resistant structure for a water conveyance tunnel passing through a large-scale active fault zone, comprising an expanded excavation section 14 crossing the fault zone, and gradual change sections 15 adjacent to the fault zone arranged at both ends of the expanded excavation section 14 crossing the fault zone.

[0025] As a preferred solution, the transition section 15 adjacent to the fault zone starts to gradually expand the tunnel section from the point where the distance from the junction 200 of the fault zone is 1 times the width of the active fault zone 100, and the length from the junction 200 of the fault zone is 0.5 times the width of the active fault zone 100 When the width of the section is enlarged, the transition section 15 adjacent to the fault zone includes the tunnel primary support layer 3, the secondary lining l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com