Door body assembly of refrigeration equipment and refrigeration equipment

A refrigeration equipment and door body technology is applied in the field of refrigeration equipment installed with the above refrigeration equipment door body components, and can solve the problems of increasing the cost of molds, the inability to share the door end covers of refrigeration equipment, and the inability to install them.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

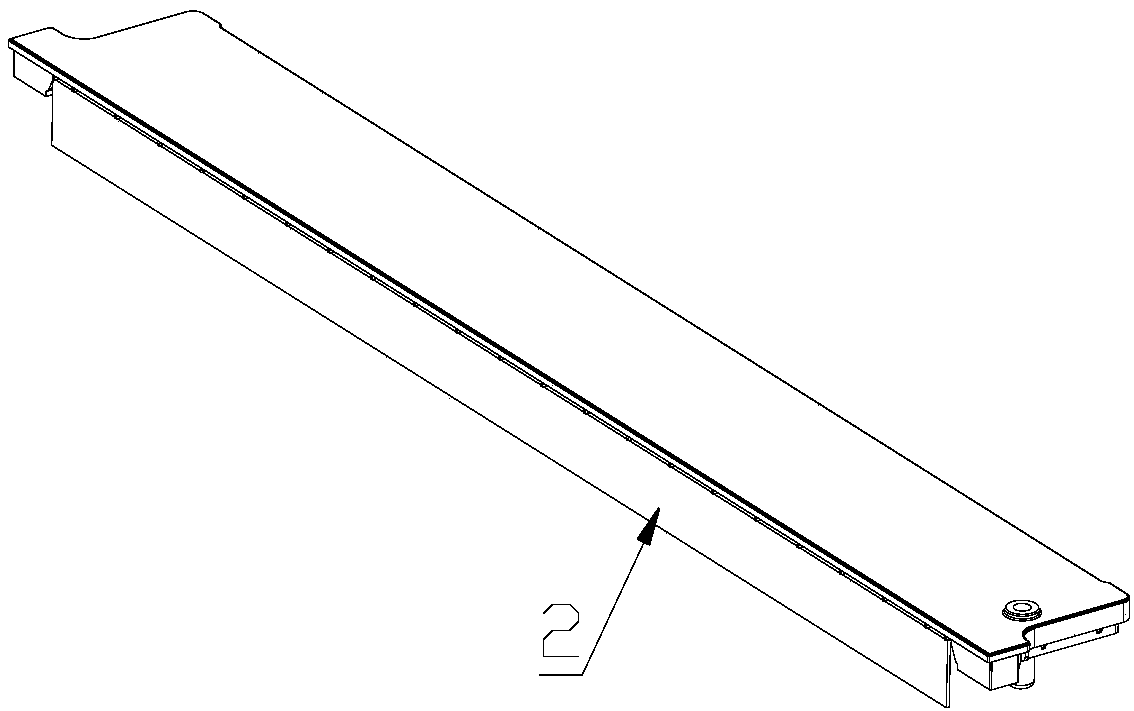

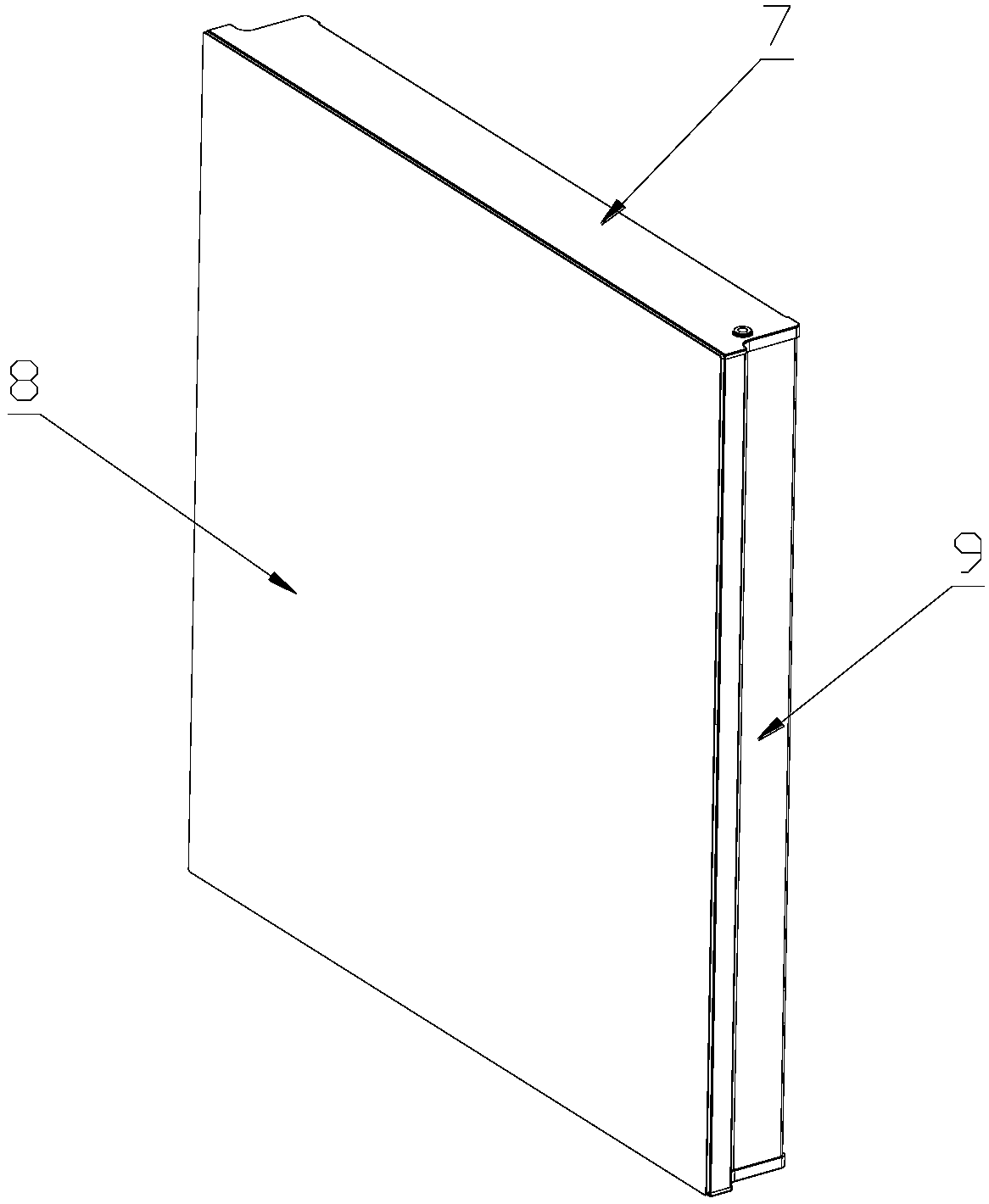

[0045] Such as figure 1 , 8, 9, 10, 13 and 14, the door body assembly of a refrigeration equipment equipped with a metal door shell 10, including the end cover 7, is divided into an upper end cover and a lower end cover due to different use positions, and is installed on the upper end. The door casing on the cover and the lower end cover, and the door lining 12 arranged opposite to the door casing. The door shell in this embodiment is a metal door shell 10 . Both sides of the metal door shell 10 are extended with columns 9, and the upper and lower ends of the metal door shell 10 are provided with door shell flanging 6, and the plane where the door shell flanging 6 is located is perpendicular to the plane where the metal door shell 10 is located.

[0046] In actual application, the structures of the upper end cover and the lower end cover are exactly the same, and the above end cover is taken as an example for detailed description below.

[0047] Such as figure 1 with Fig...

Embodiment 2

[0056] Such as figure 1 , 8 , 9, 11, 13 and 14, the difference between this embodiment and Embodiment 1 is that in this embodiment, on the upper side wall of the groove 1, along the length direction of the groove 1, there are many A rib 5 on the upper side wall.

[0057] The outer end surface of the upper side wall reinforcing rib 5 does not protrude from the second outer side 3. In practical application, it is ensured that the outer end surface of the upper side wall reinforcing rib 5 and the second outer side 3 are in the same vertical plane.

[0058] The perpendicularity between the upper side wall reinforcing rib 5 and the lower side wall of the groove 1 is specifically equal to 5 mm.

[0059] The bottom surface of the upper side wall reinforcing rib 5 and the outer end surface of the upper side wall reinforcing rib 5 transition through a second arc surface.

[0060] Such as Figure 11 with 14 As mentioned above, when the metal door shell 10 with the door shell flange...

Embodiment 3

[0062] Such as figure 1 , 8 , 9, 12, 13 and 14, the present embodiment includes both embodiment one and embodiment two, both the lower side wall rib 4 and the upper side wall rib 5, so that the lower side wall rib 4 The vertical distance from the upper side wall reinforcing rib 5 is equal to the thickness of the flange of the metal door shell, that is, 5 mm.

[0063] The top surface of the lower sidewall reinforcing rib 4 and the end surface of the lower sidewall reinforcing rib 4 away from the bottom wall of the groove 1 are transitioned through a first arc surface. The bottom surface of the upper side wall reinforcing rib 5 and the outer end surface of the upper side wall reinforcing rib 5 transition through a second arc surface.

[0064] Such as Figure 12 with 14 As mentioned above, when the metal door shell 10 with the door shell flange 6 is installed on the upper end cover and the lower end cover, the door shell flange 6 is plugged into the upper side wall reinforcem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com