Hydraulic bushing

A casing and hydraulic technology, applied in the direction of shock absorbers, springs, spring/shock absorbers, etc., can solve problems such as cost, and achieve the effect of simplifying access and filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

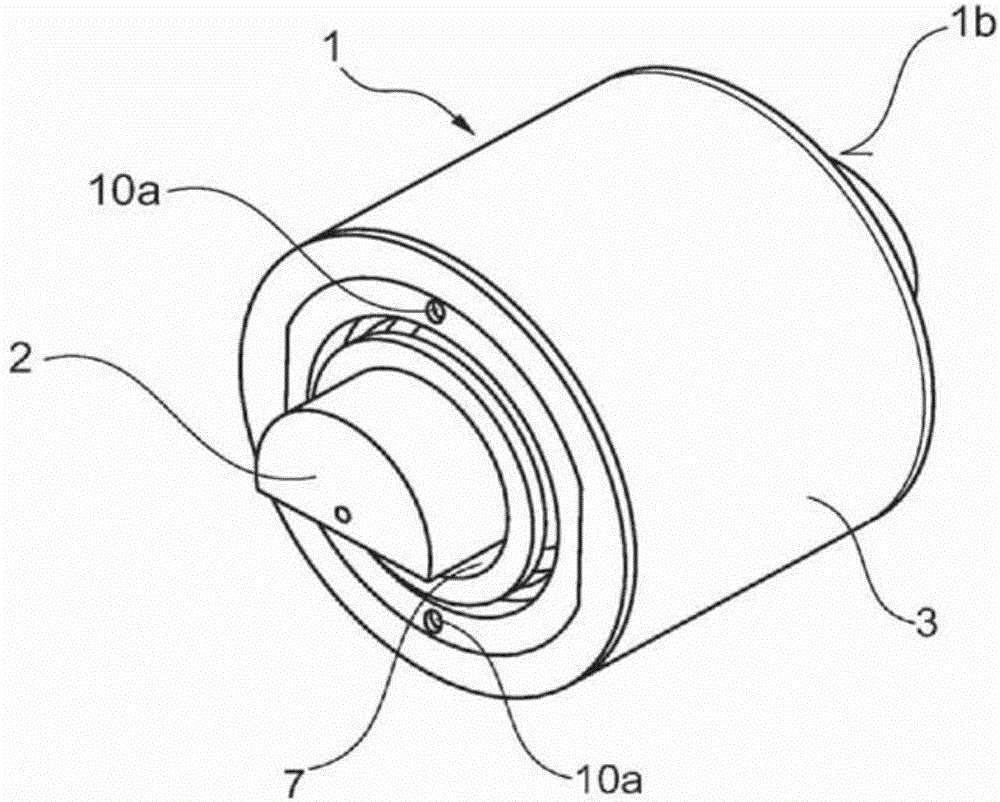

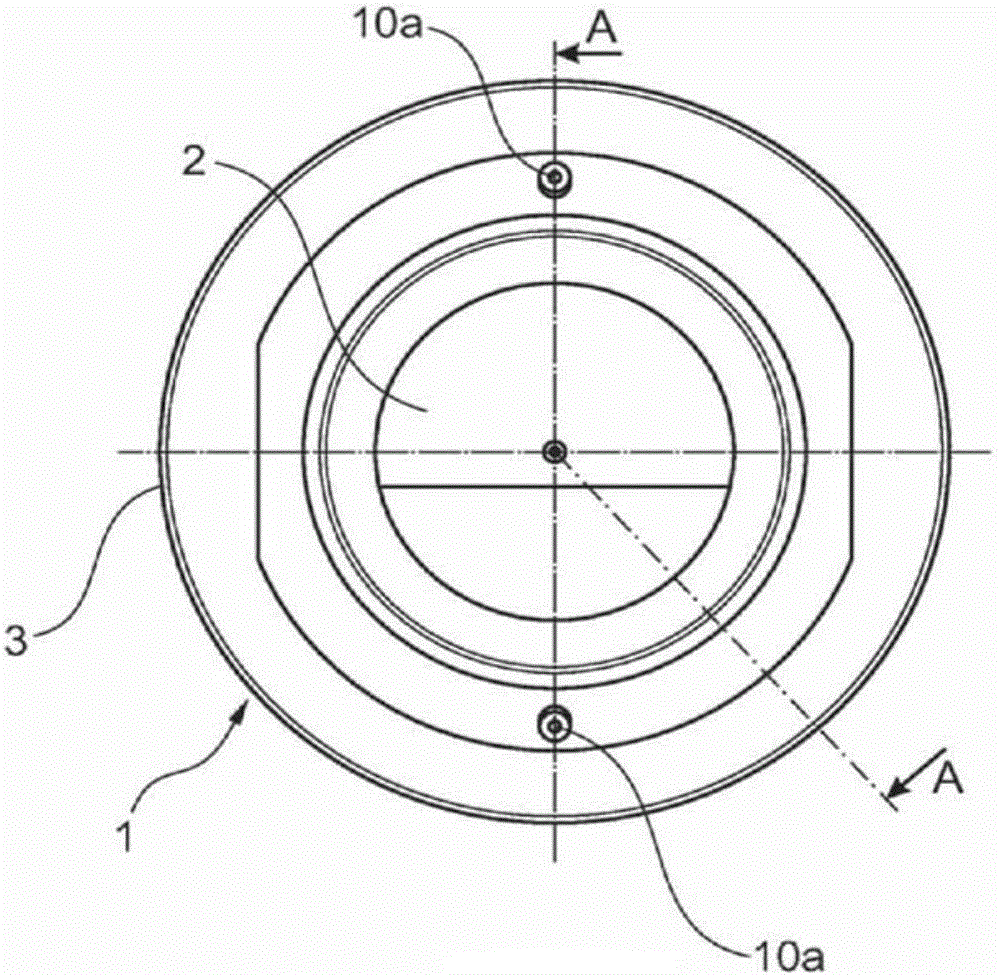

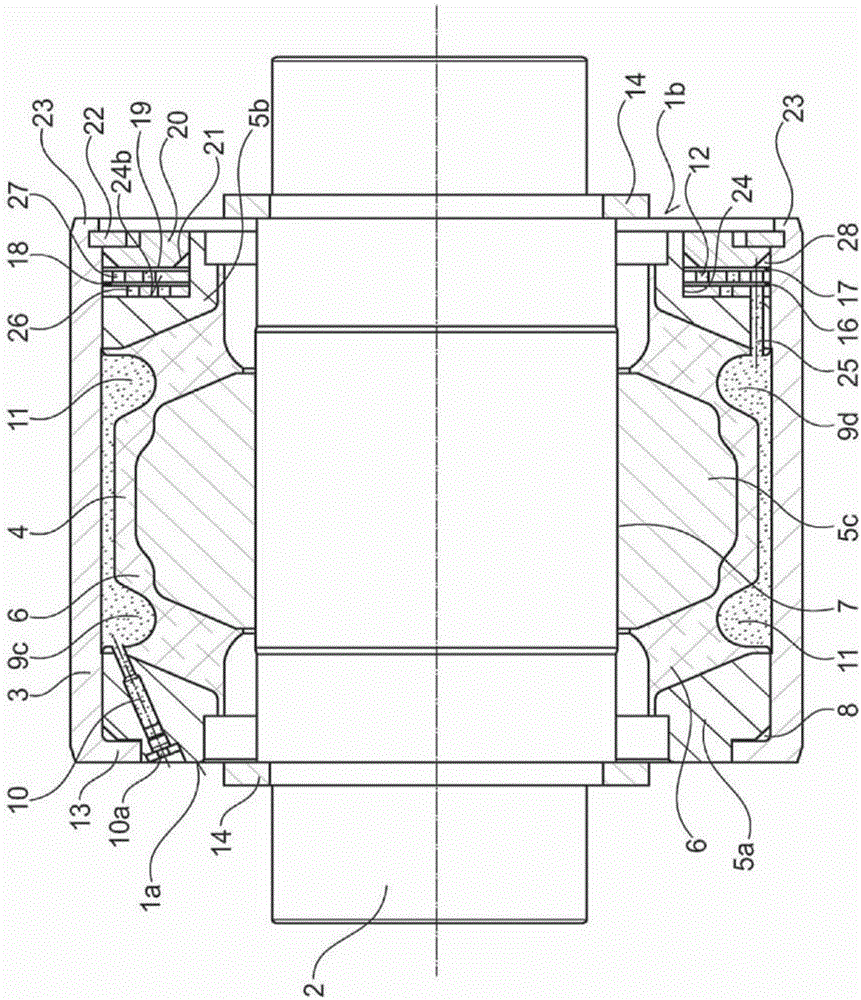

[0047] according to figure 1 A hydraulic bushing 1 according to the invention to be applied as a wheel set guide bushing for a rail vehicle is formed as a hollow cylinder which receives a steering pin 2 of a steering linkage of the rail vehicle. The steering pin 2 has a flattened portion for receiving the steering pin in the crossbar of the steering linkage in a rotationally fixed manner. The bushing 1 has a substantially sleeve-shaped outer housing element 3, for example in image 3 As shown in , the outer housing element radially surrounds an inner, substantially cylindrical housing element 5c forming an annular gap 4 . For example in image 3 As shown in , a rubber-elastic spring element, namely an annular spring element 6 , is arranged in the annular gap 4 .

[0048] At each end side 1a, 1b of the hydraulic bushing 1 there is arranged an axially outwardly arranged annular frame element 5a, 5b which co-operates with the housing elements 3, 5c and the annular spring eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com