Shock wave reversing release system

A release system and shock wave technology, applied in the field of boiler soot blowing, can solve the problems of limited soot blowing range, difficulty in improving soot blowing efficiency, etc., achieve good ash removal effect, improve operation efficiency, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

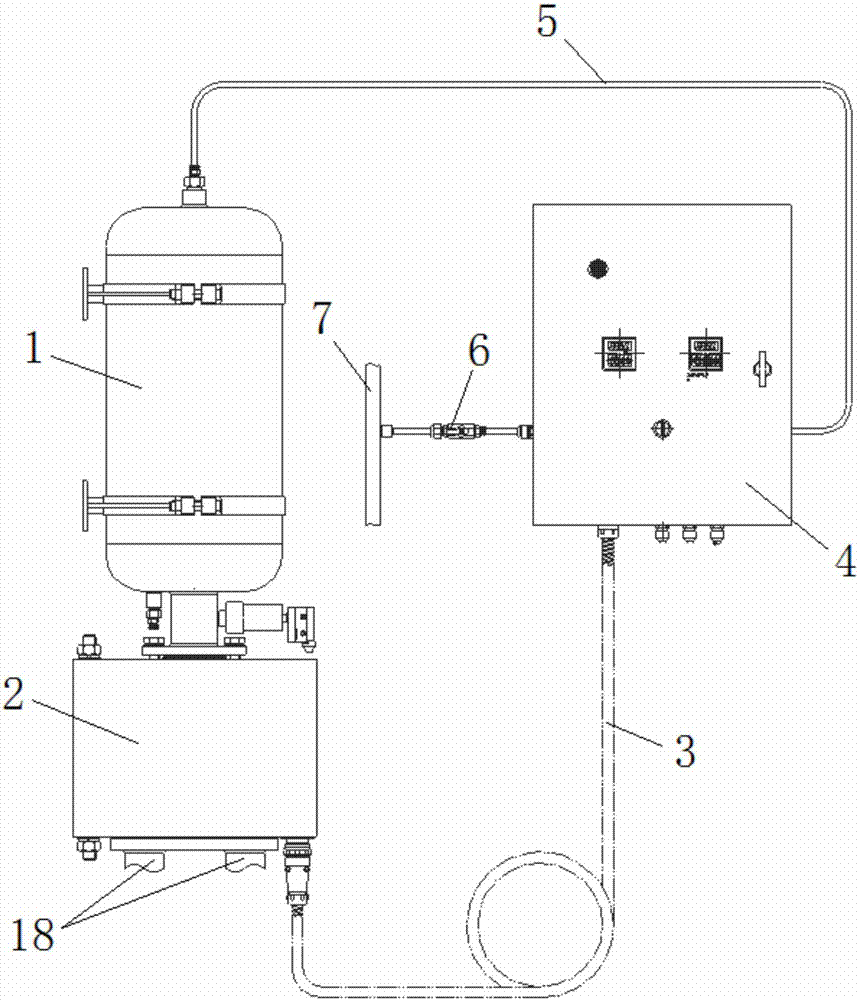

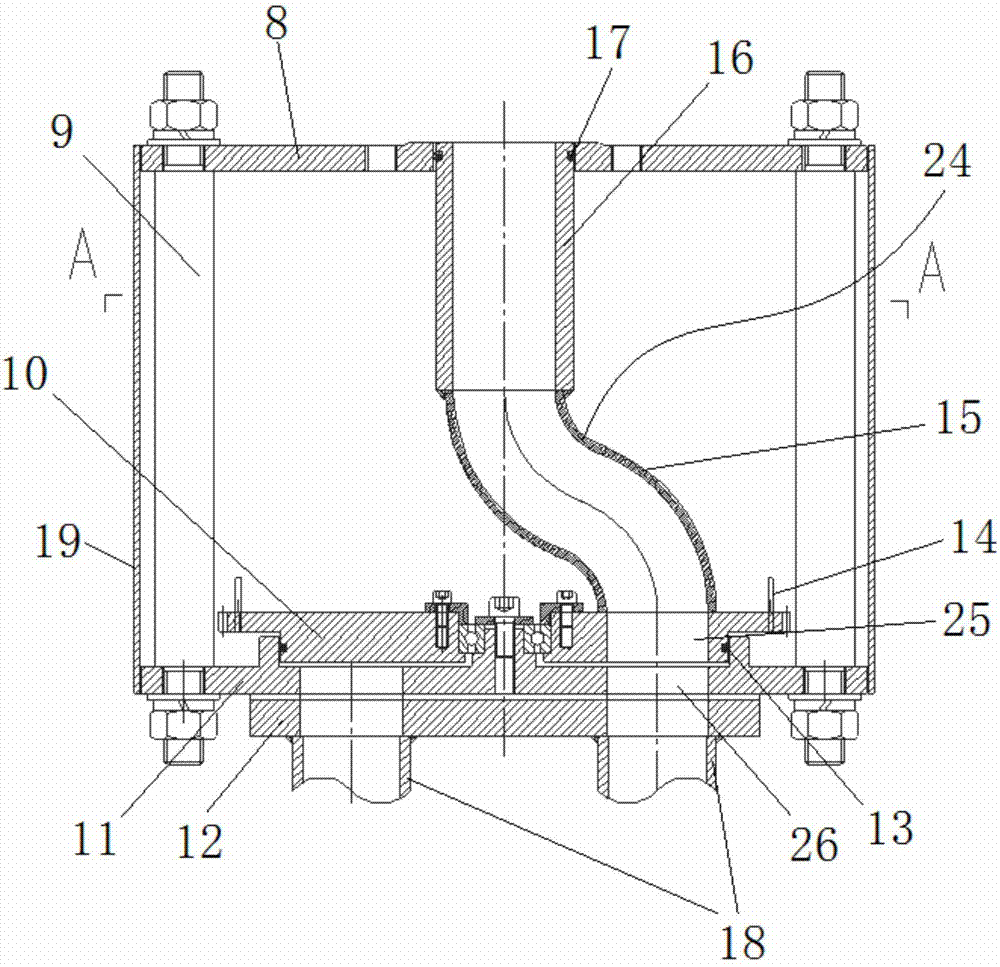

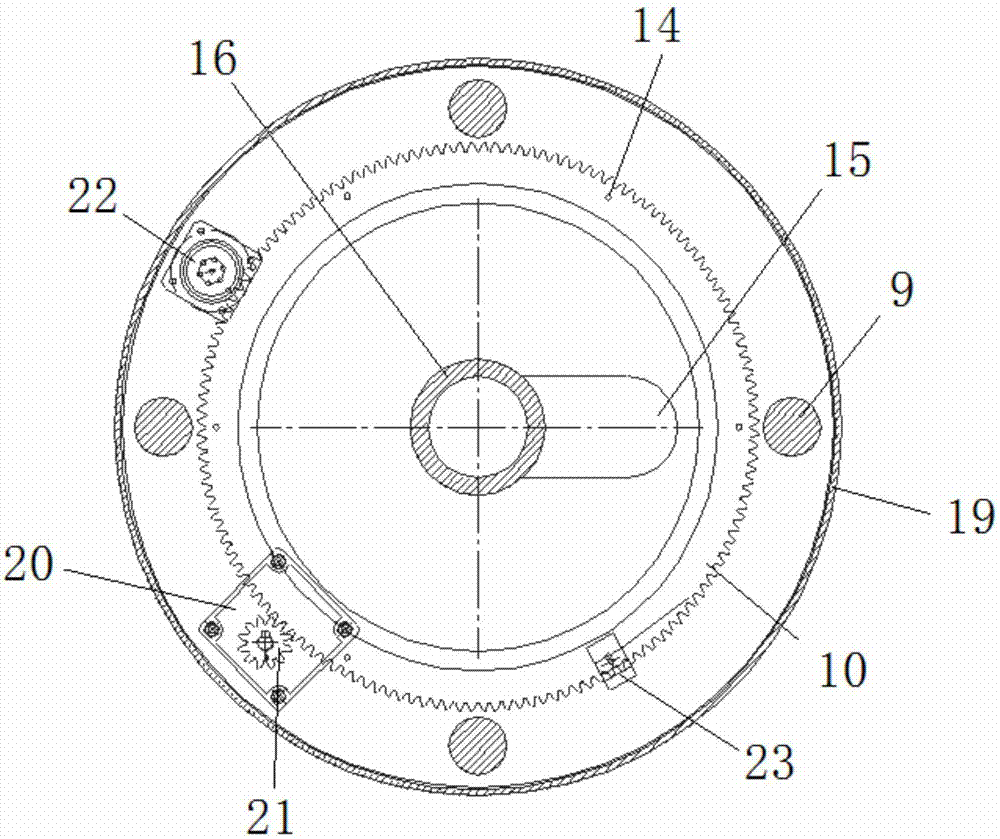

[0025] like Figure 1~4 As shown, the present invention includes a shock wave generating device 1, a shock wave conversion mechanism 2 and a control unit 4, wherein the shock wave generating device 1 is provided with a fixed bracket, and the shock wave generating device 1 is installed on the boiler body through the fixed bracket, Both the output end of the shock wave generator 1 and the input end of the shock wave conversion mechanism 2 are provided with flanges, and the output end of the shock wave generator 1 and the input end of the shock wave conversion mechanism 2 are connected through flanges. A connecting pipe 24, a rotating disk 10 and a driving device 20 are arranged in the shock wave conversion mechanism 2, and a grinding disc orifice plate 11 and a plurality of soot blowing branch pipes 18 are arranged at the output end of the shock wave conversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com