Joint mechanism for humanoid robot

A robot and human-like technology, applied in the direction of robots, manipulators, mechanical equipment, etc., can solve problems such as the reduction of torque transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

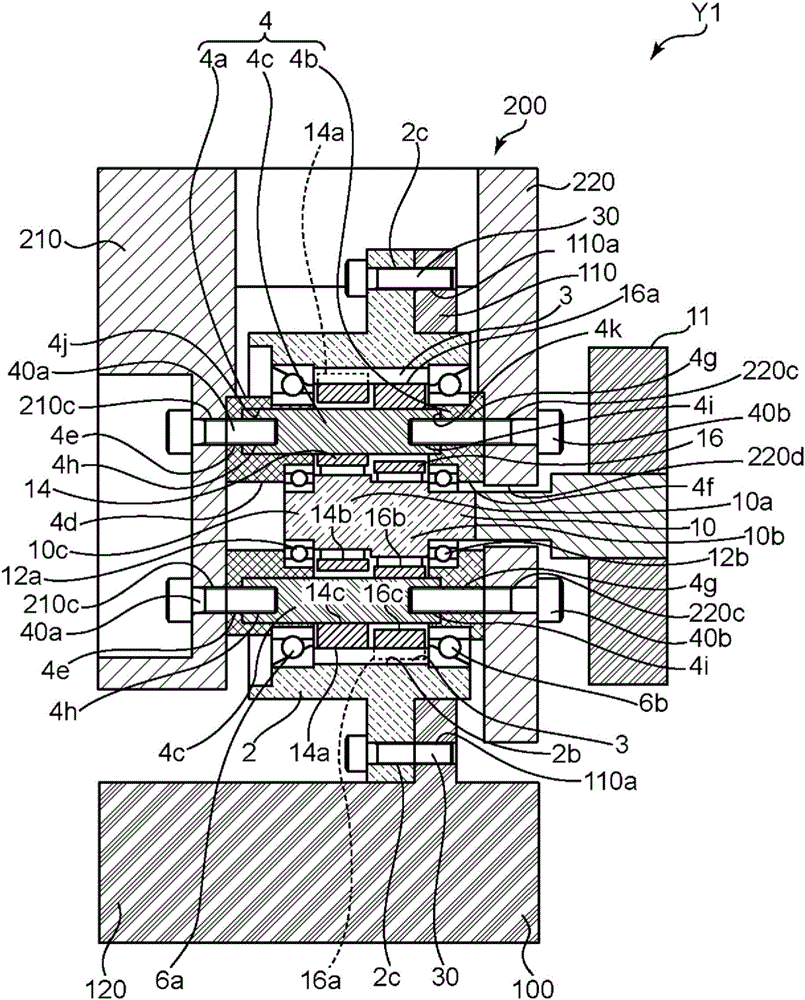

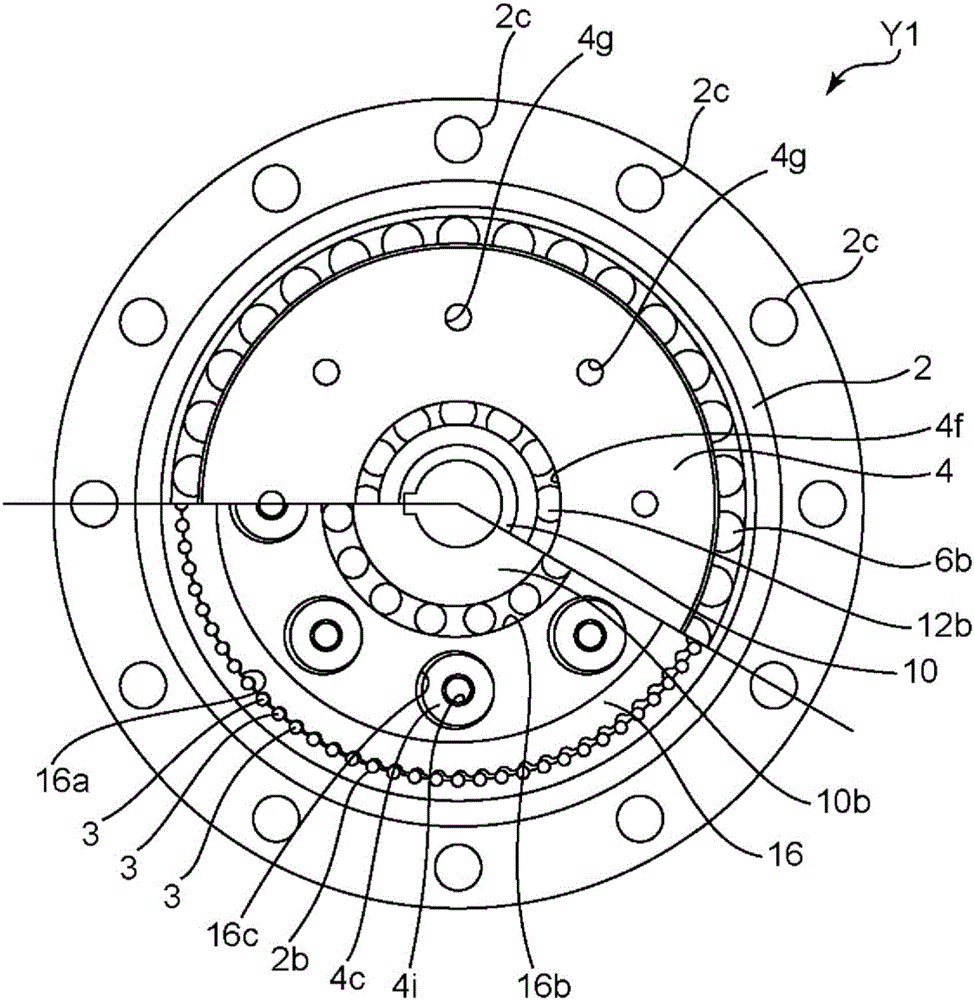

[0017] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. However, for convenience of description, each of the drawings referred to below simplifies the main members necessary for the description of the present embodiment. Therefore, the joint mechanism of the humanoid robot according to the present embodiment may include arbitrary constituent members not shown in the drawings referred to in this specification.

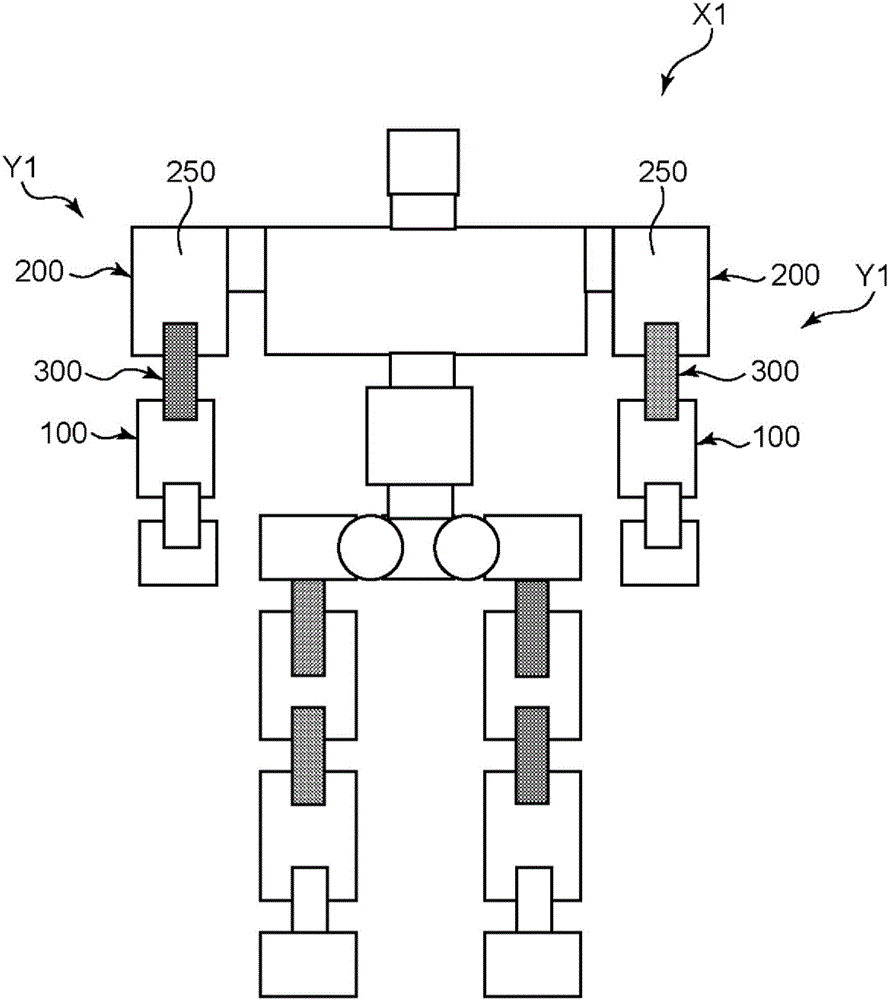

[0018] Such as figure 1 As shown, the humanoid robot X1 of this embodiment is a humanoid robot having a plurality of joints. The humanoid robot X1 includes a joint mechanism Y1, and the joint mechanism Y1 includes: a first member 100, which constitutes a part from the hand to an elbow; a second member 200, which constitutes a part from the elbow to a shoulder; and a gear device 300, which constitutes an elbow. part and realize the relative rotation between the first member 100 and the second member 200 . In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com