A compartment type relief valve and its working method

A relief valve, compartment technology, used in safety valves, valve operation/release devices, valve details, etc., can solve problems such as low tank pressure and main valve opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

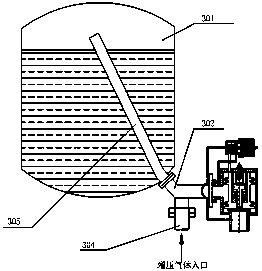

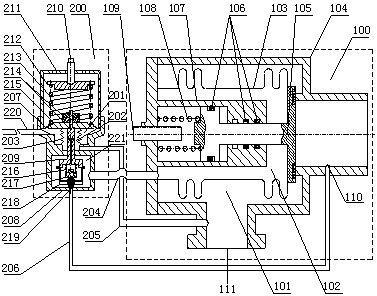

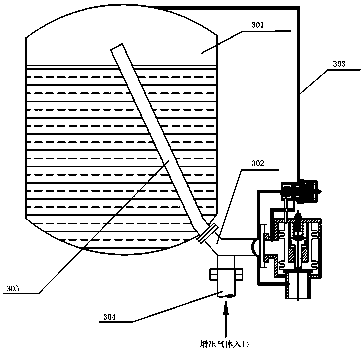

[0029] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0030] Such as figure 2 As shown, a compartment type relief valve in the embodiment of the present invention includes a main valve 100 and a command valve 200, the main valve 100 includes a main valve chamber 101 and a back pressure chamber 102, the main valve chamber 101 and a back pressure chamber 102 are separated by a bellows assembly 103, the command valve 200 includes a control chamber 201 and a feedback chamber 202, the control chamber 201 and the feedback chamber 202 are separated by a bellows 203, the feedback chamber 202 and the deflation chamber 221 They are connected or disconnected through the live valve 217, the deflation chamber 221 is connected with the back pressure chamber 102 through the communication pipe 204, the feedback chamber 202 is connected with the main valve chamber 101 through the drainage pipe 205, the command valve gas outlet 219 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com