Combined type fast self-absorption centrifugal pump

A centrifugal pump and compound technology, applied in the field of compound fast self-priming centrifugal pumps, can solve the problems of inability to work normally, inconvenient to move, long self-priming time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

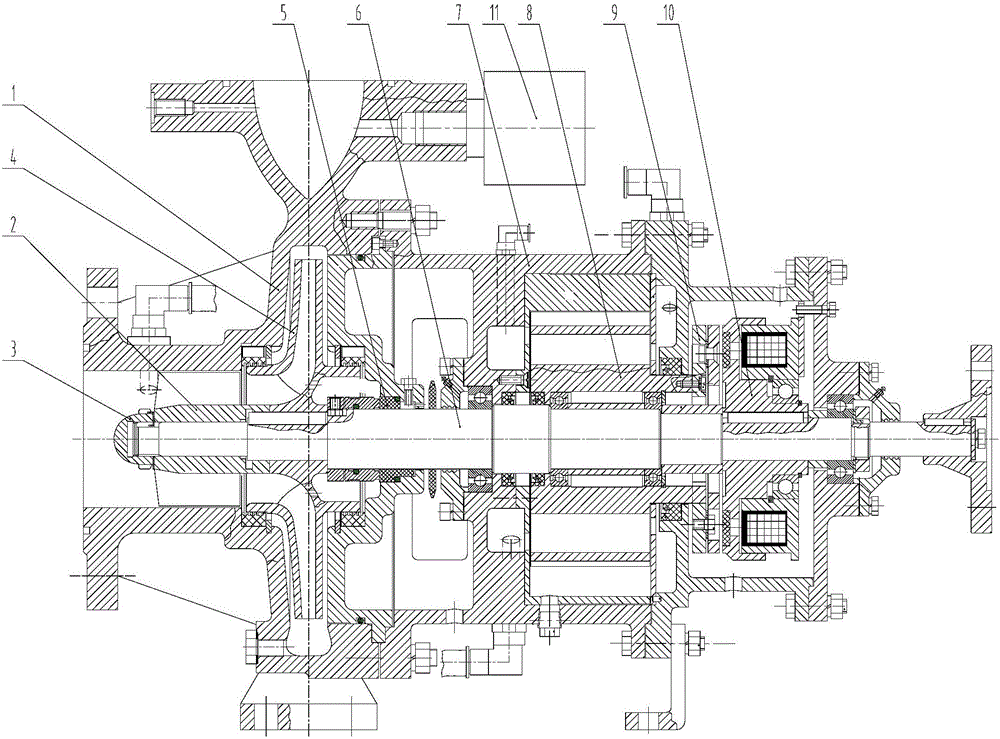

[0024] see figure 1 Shown: install the impeller 4 and the inducer 2 on the main shaft 6, the inducer 2 is located at the front end of the impeller 4, install the lock nut 3 and the shaft head screw stop washer in front of the inducer 2 to press the inducer 2 and the impeller 4 tight. When installed, the position of impeller 4 is in the water outlet channel of shell 1, and its function is to discharge the medium that has passed through impeller 4 through the flow channel of shell 1 under pressure; the position of inducer 2 is in the water inlet pipe of shell 1, so that the medium can be discharged under pressure. The impeller 4 passes through the action of the inducer 2 before the action, so as to improve the anti-cavitation performance. The casing 1 and the engine are fixed together with a bracket 7 to ensure the running stability of the unit.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com