Preparation method and application of a class of six-membered dinitroheterocyclic derivatives containing four identical substituents

A technology for bis-nitroheterocycles and derivatives, applied in the field of preparation of six-membered bis-aza-heterocycle derivatives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: the synthesis of derivative M1

[0044]

[0045] Add 1.69g (10.10mmol) carbazole into a 250ml three-necked flask, then add 100mL N,N-dimethylformamide as a reaction solvent, and stir on a magnetic stirrer for 10min. Under the condition of ice bath, 0.49g (20.19mmol) NaH was added to the reaction flask in batches, and the stirring was continued for 1h. 0.50g (2.30mmol) of 3,4,5,6-tetrachloropyridazine was dissolved in 20ml of N,N-dimethylformamide, and added dropwise to the reaction system. After the addition was complete, under nitrogen protection, Reaction at 60°C for 15h. After the reaction is over, pour the reaction solution into 150ml of dilute hydrochloric acid with a concentration of 10% to quench, filter under reduced pressure, wash with water, and dry the crude product with petroleum ether and ethyl acetate (PE:EA=10:1) Perform column chromatography as the mobile phase to remove impurities, and then use pure dichloromethane (DCM) to flush the ...

Embodiment 2

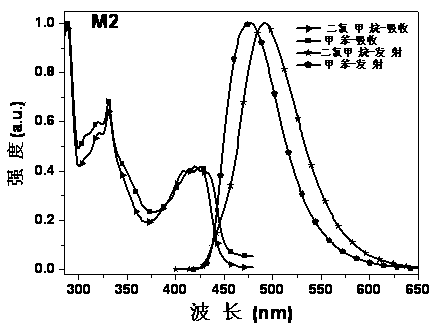

[0046] Embodiment 2: the synthesis of derivative M2

[0047] method 1)

[0048]

[0049]Add 1.35g (8.08mmol) carbazole into a 250ml three-neck flask, then add 100mL N,N-dimethylformamide as a reaction solvent, and stir on a magnetic stirrer for 10min. Under the condition of ice bath, 0.39g (16.16mmol) NaH was added to the reaction flask in batches, and the stirring was continued for 1h. 0.40g (1.84mmol) of 2,3,5,6-tetrachloropyrazine was dissolved in 20ml of N,N-dimethylformamide, and added dropwise to the reaction system. After the addition, under nitrogen protection, 60 Reaction at ℃ for 15h. After the reaction is over, pour the reaction solution into 150ml of dilute hydrochloric acid with a concentration of 10% to quench, filter under reduced pressure, wash with water, and dry the crude product with petroleum ether and ethyl acetate (PE:EA=10:1) Perform column chromatography as the mobile phase to remove impurities, and then use pure dichloromethane (DCM) to flush the...

Embodiment 3

[0053] Both method (1) and method (2) in Example 3 can obtain the target product M2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com