control loop

A technology of control rings and fasteners, applied in the field of control gauges, can solve the problems of expensive purchase and maintenance, fragile, bulky, etc., and achieve the effect of reducing the risk of wrong positioning and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

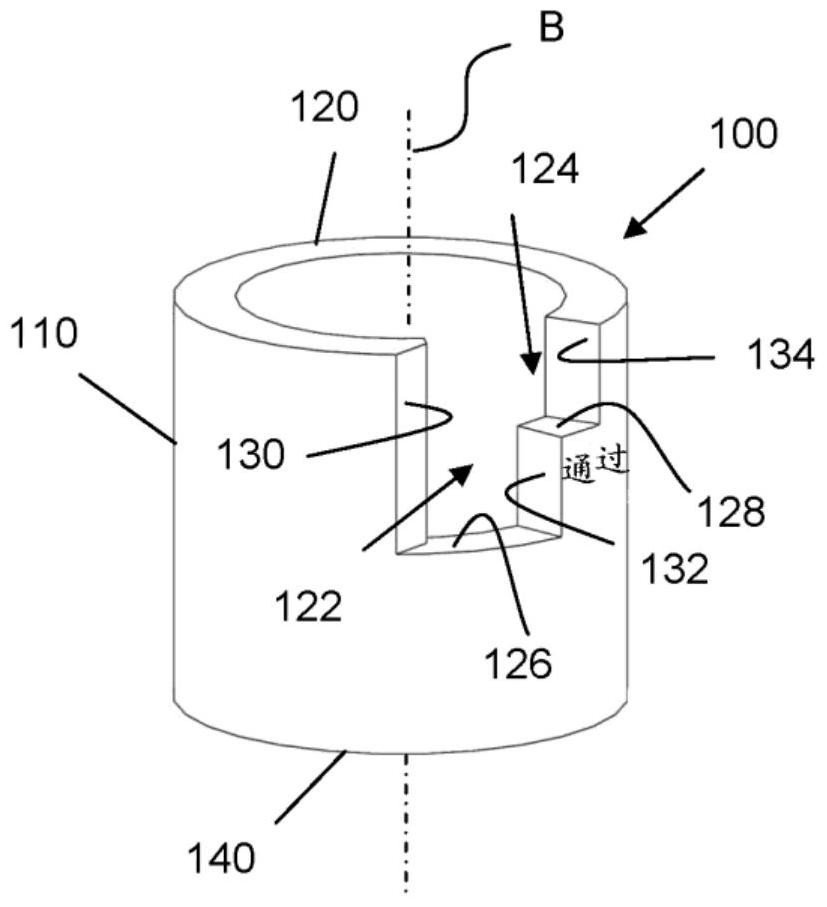

[0053] figure 2 A first embodiment of a control loop 100 according to the invention is shown. The control ring 100 comprises a tubular body 110 with an axis of rotation B, which is equipped with a through-hole which emerges at a first extreme end 120 of said tubular body and at a second extreme end 140 opposite the first extreme. The ring is made of aluminum, for example. The inner diameter of the ring is matched within a tolerance to the outer diameter of the shaft 14 of the fastener to be inspected so that the ring can slide on the shaft 14 without excessive resistance.

[0054] The first end 120 of the body includes two U-shaped notches 122 and 124 that extend axially from the end 120 through a portion of the body 110 to end walls 126 and 128 , respectively. The end walls 126 and 128 extend in parallel planes perpendicular to the axis B and are axially offset from each other. The two notches 122 and 124 are adjacent and have different axial lengths and widths (or arcuat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com