Spinning station for an air spinning machine, air spinning machine and method for operating air spinning machine

An air-jet spinning machine and spinning technology, applied in the field of spinning stations, can solve problems such as unfavorable production process efficiency, stagnation of spinning station production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following description of the figures, the same reference symbols are used for features which are respectively identical and / or at least similar in different figures. Often, individual features, their configuration and / or mode of operation are only explained in detail when they are mentioned for the first time. If the individual features are not explained in more detail, their configuration and / or mode of operation correspond to those already described for identically acting or identically named features.

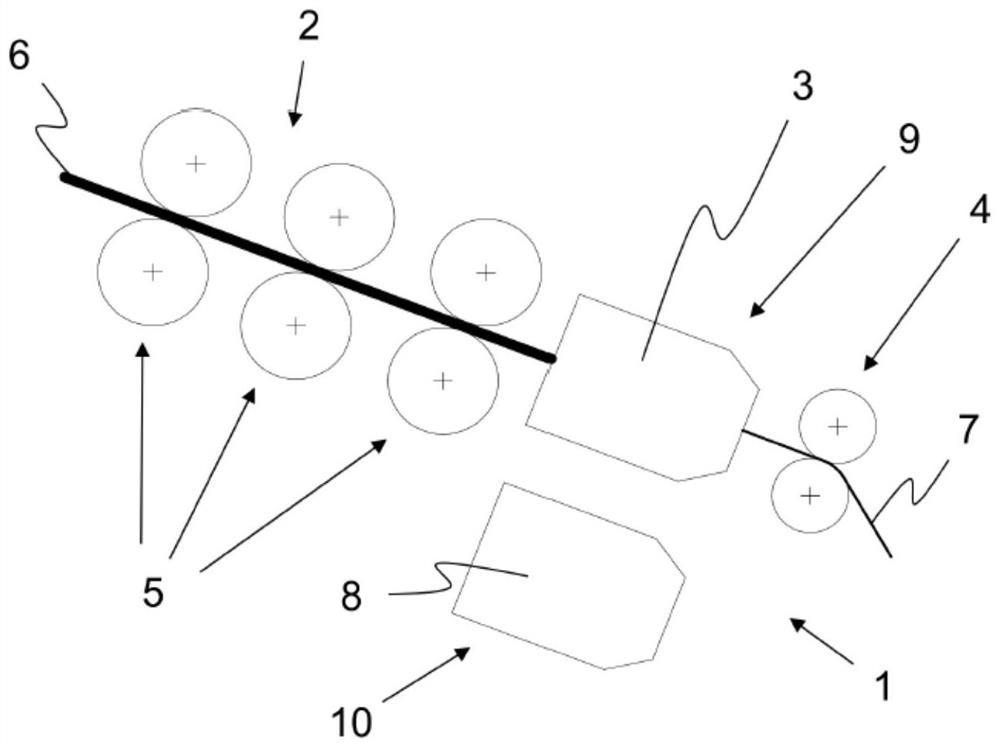

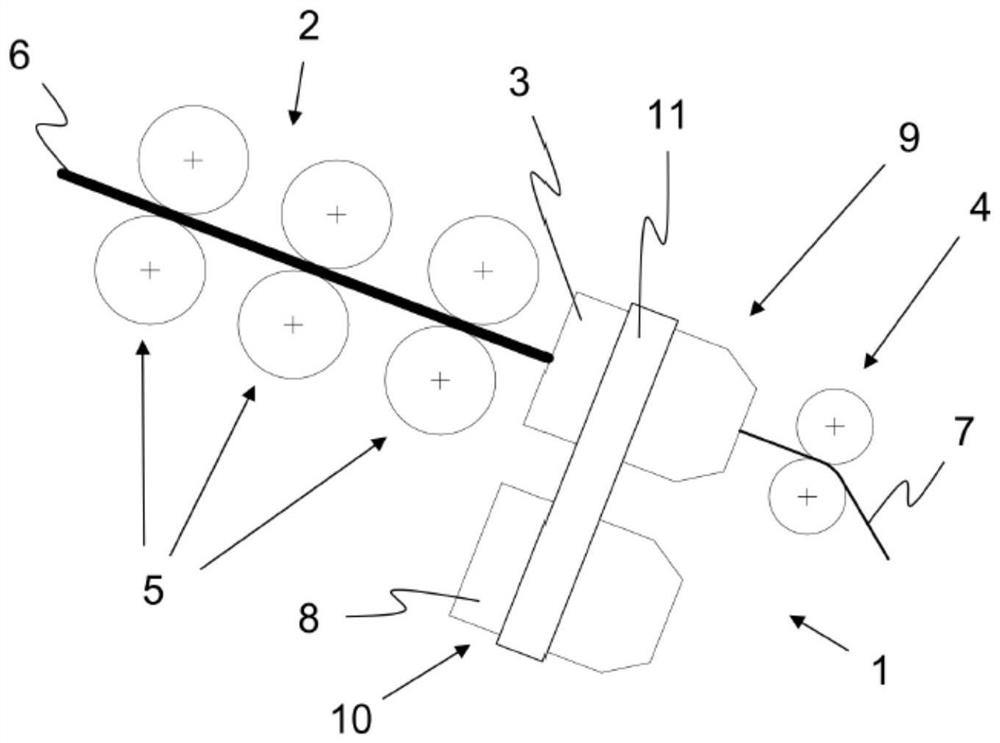

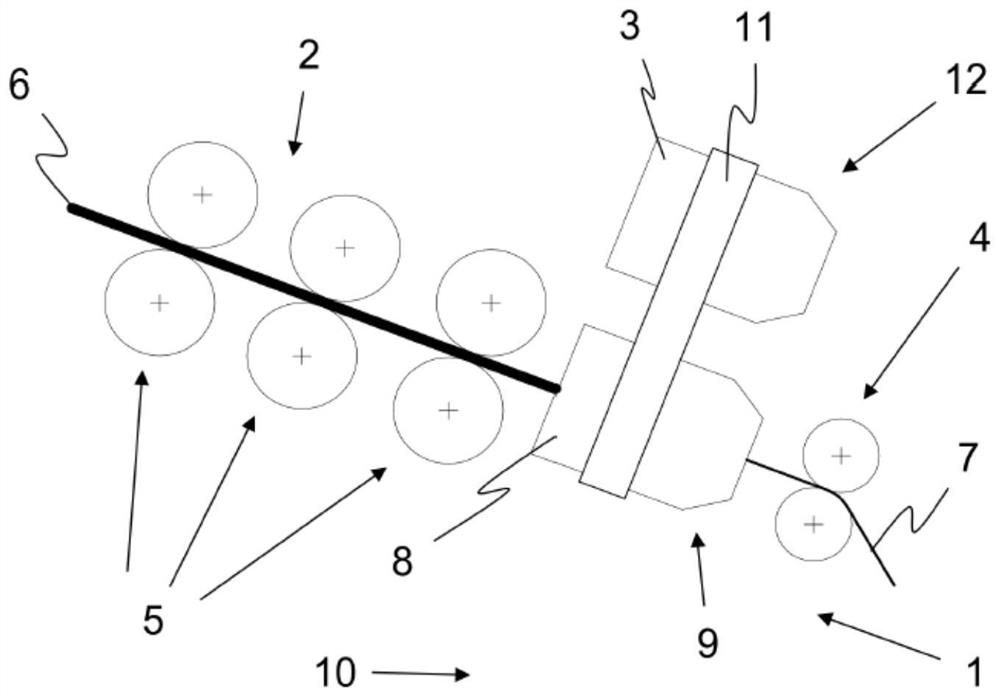

[0032] figure 1 A first schematic view of a spinning station 1 according to the invention is shown. The spinning station 1 comprises a drafting device 2 , a first spinneret 3 and a pair of take-off rollers 4 . The drafting device 2 in turn comprises a plurality of drafting device roller pairs 5 for drafting the fiber strip 6 . The pairs of drafting rollers 5 can, for example, rotate at different speeds. The fiber strip 6 is fed to a first spinneret 3 in whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com