Fully-automatic in-mold injection molding system

An in-mold injection molding and fully automatic technology, applied in the direction of coating, etc., can solve the problems of low efficiency, mold damage, injection molding quality and efficiency not meeting daily needs, etc., and achieve the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the examples, and the contents mentioned in the embodiments are not intended to limit the present invention.

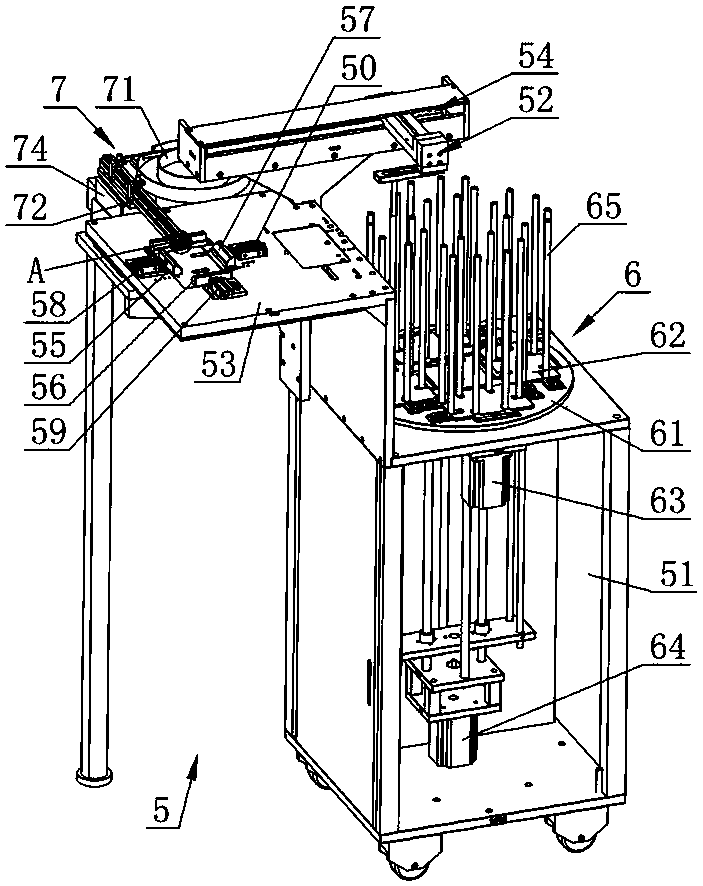

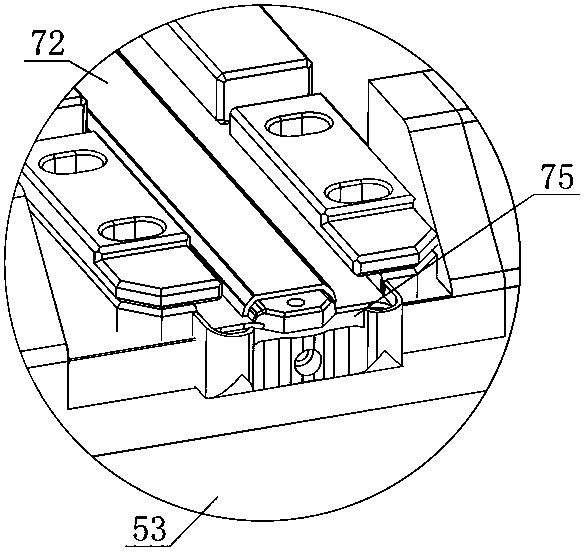

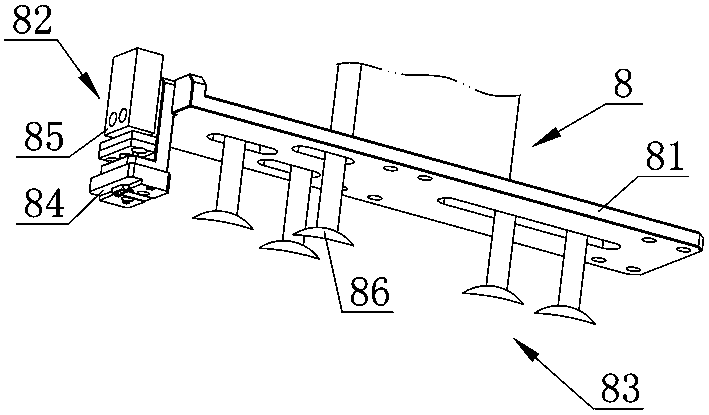

[0026] Such as Figure 1 to Figure 9 As shown, a fully automatic in-mold injection molding system includes a feeding device 5 and an in-mold injection mold 19, and the feeding device 5 includes a frame 51, a first feeding assembly 6 and a second feeding assembly installed on the frame 51. The feeding assembly 7, the first feeding assembly 6 includes a rotating disk 61 and a top material block 62 installed on the rotating disk 61, the second feeding assembly 7 includes a first feeder 71 and a feeder connected to the first feeder 71 The conveying path 72, the frame 51 is equipped with a first picking claw 52, a positioning platform 53 and a second picking claw 8 connected to the positioning platform 53, and the in-mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com