Test device for cumulative damage of tunnel bottom structure under cyclic loading

A bottom structure and cumulative damage technology, applied in the direction of machine/structural component testing, measuring devices, instruments, etc., to achieve the effect of solving the mismatch between the constraint pressure and surrounding rock conditions and accurate test simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

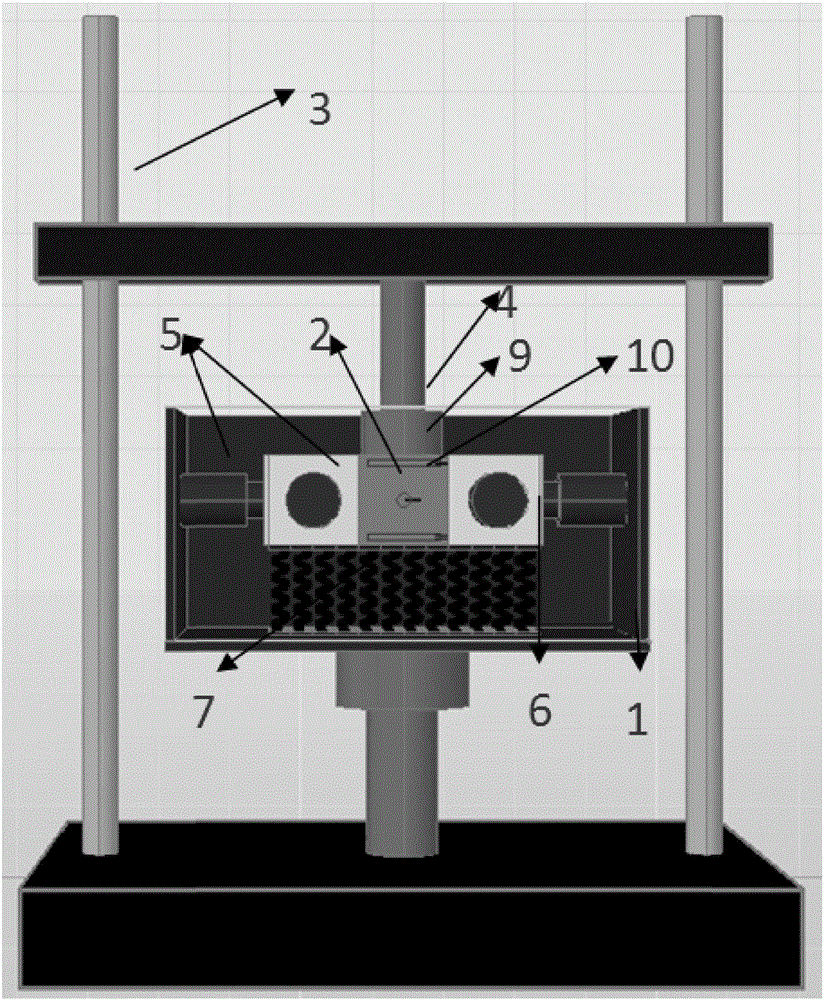

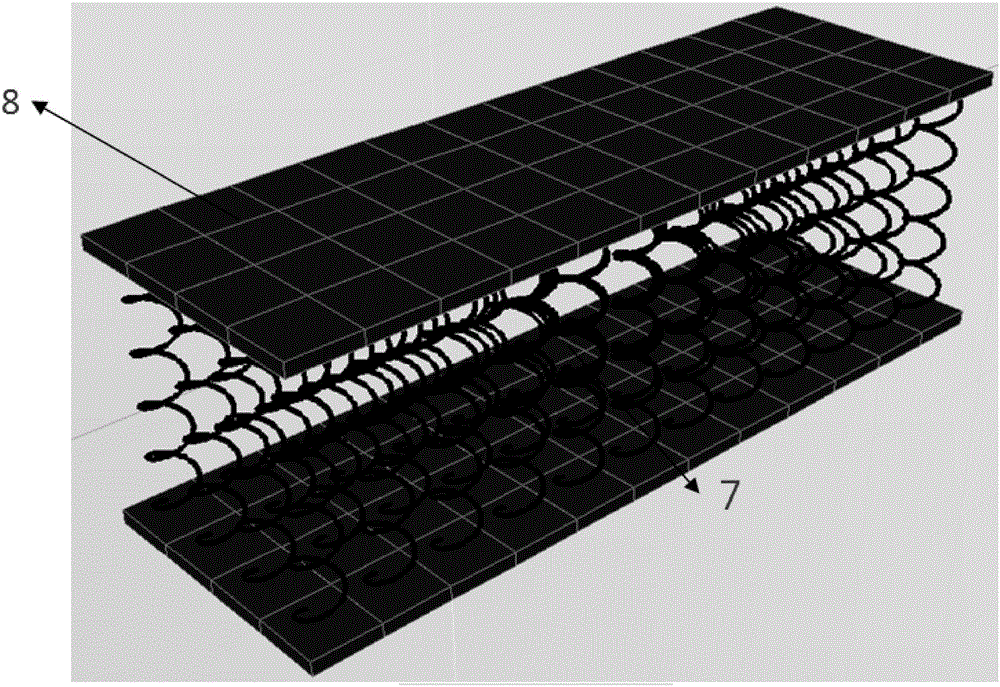

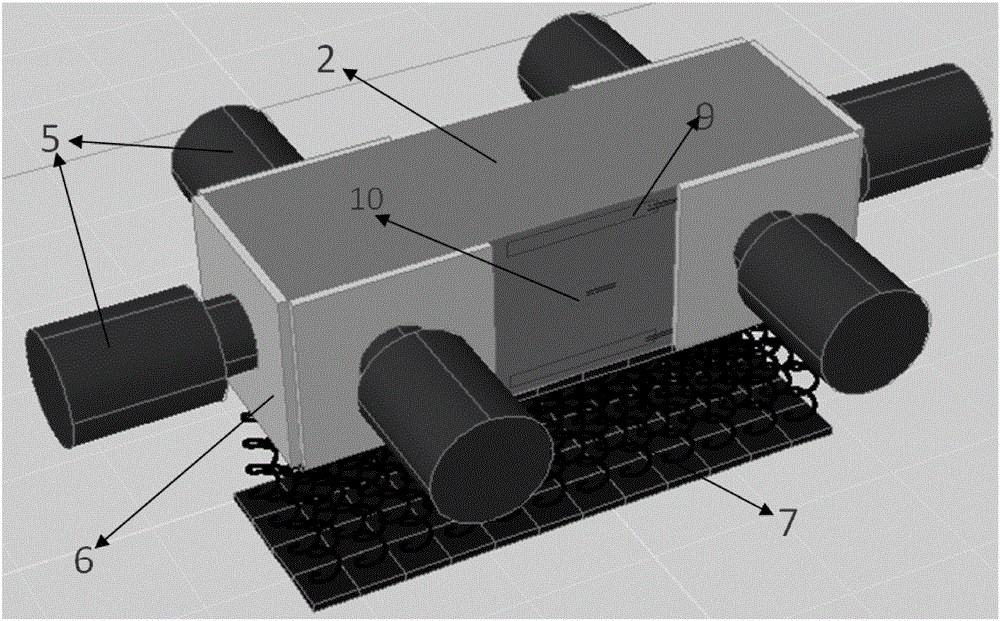

[0028] In the present invention, through an in-depth analysis of the stressed state of the tunnel bottom structure, it is determined that the bottom spring is used to simulate the constraint effect of the surrounding rock at the bottom of the tunnel on the bottom structure, and a group of densely distributed springs with the same stiffness are used to simulate the uniform confining pressure at the bottom of the tunnel In view of the fact that the bottom of the tunnel may have local voids, softening, and construction defects in actual construction, the test can quantitatively simulate the detachment of the surrounding rock at the bottom by reducing the number of springs at the bottom of the specimen or adjusting the arrangement of the springs. In the empty state, the local damage and softening phenomenon of the surrounding rock at the bottom of the tunnel can be simulated by reducing the stiffness of some springs; the quantitative application of uneven constraint pressure at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com