An electric heating device and assembly process for simulating nuclear reactor fuel rods

A technology of nuclear reactor fuel and electric heating device, which is applied in the fields of nuclear reactor monitoring, reactor, nuclear engineering, etc., can solve the problem of no retrieval, etc., and achieve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

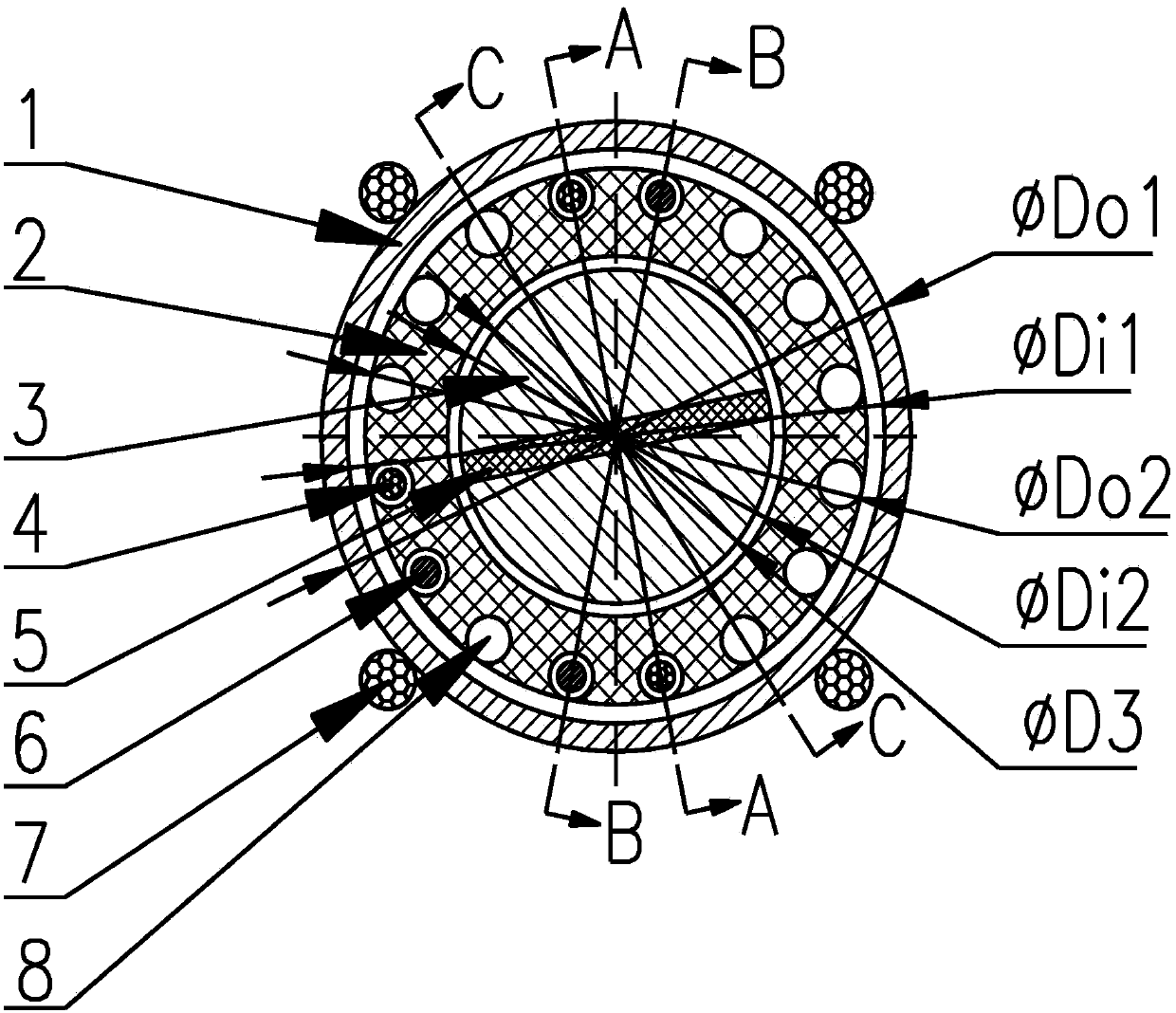

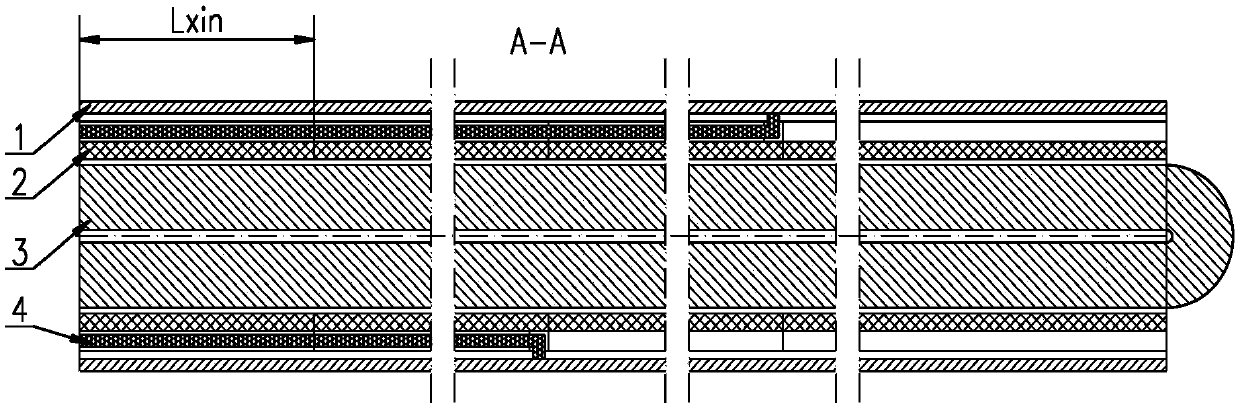

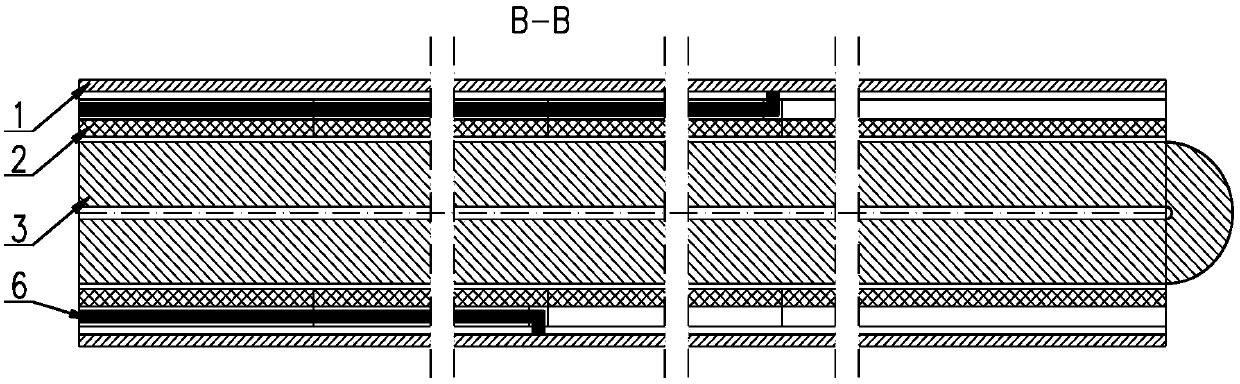

[0056] Such as Figures 1 to 4 As shown, the present invention is an electric heating device for simulating nuclear reactor fuel rods, including a simulated cladding 1, and a plurality of simulated fuel element pellets 2 stacked in the axial direction of the simulated cladding 1 are arranged in the simulated cladding 1 , the cross-section of the simulated fuel element pellet 2 is an annular structure, and 16 through holes 8 extending along its axial direction are arranged on the simulated fuel element pellet 2, and thermoelectric Coupled wire positive electrode 4, a thermocouple wire negative electrode 6 is installed in part of the through holes 8, and inert gas is stored in the remaining through holes 8; Electric heating rod 3; the electric heating rod 3 is made of tungsten, molybdenum, tungsten-molybdenum alloy or molybdenum-copper alloy. An insulating layer 5 is installed in the gap, and a plurality of external wall temperature thermocouples 7 are installed outside the sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com