Positioning and clamping tool for laser welding of stainless steel side wall

A laser welding, positioning and clamping technology, which is applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problem that the laser welding scheme cannot be implemented, affects the streamline and aesthetics of the curved surface, and the outer wall of the side wall is compressed and deformed, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

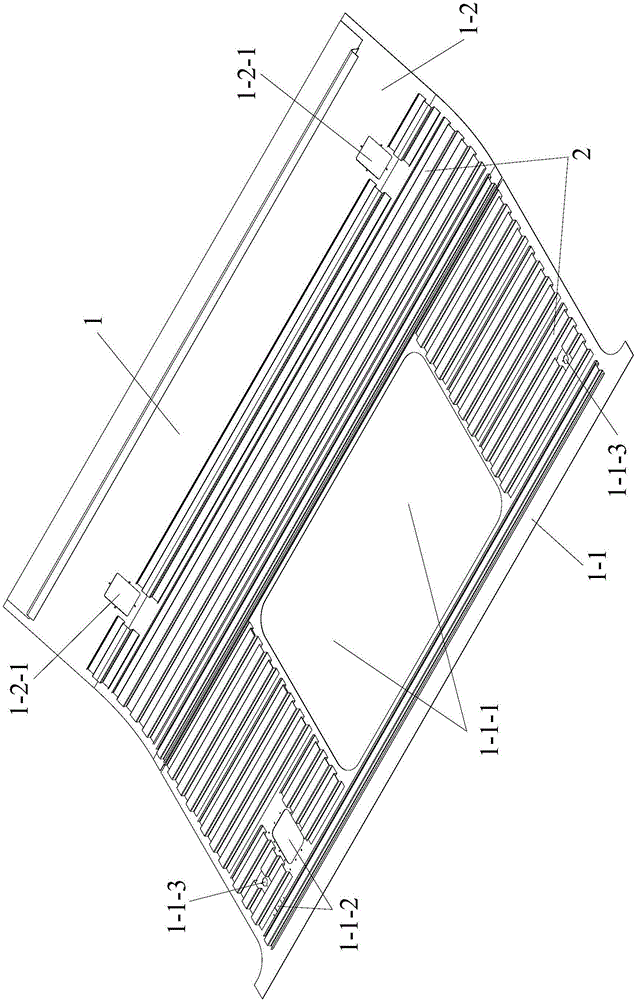

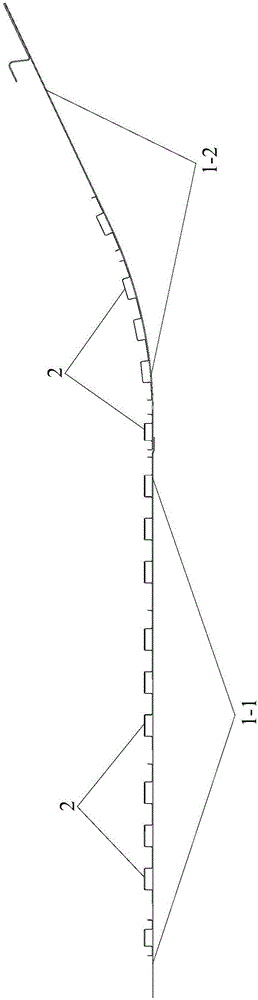

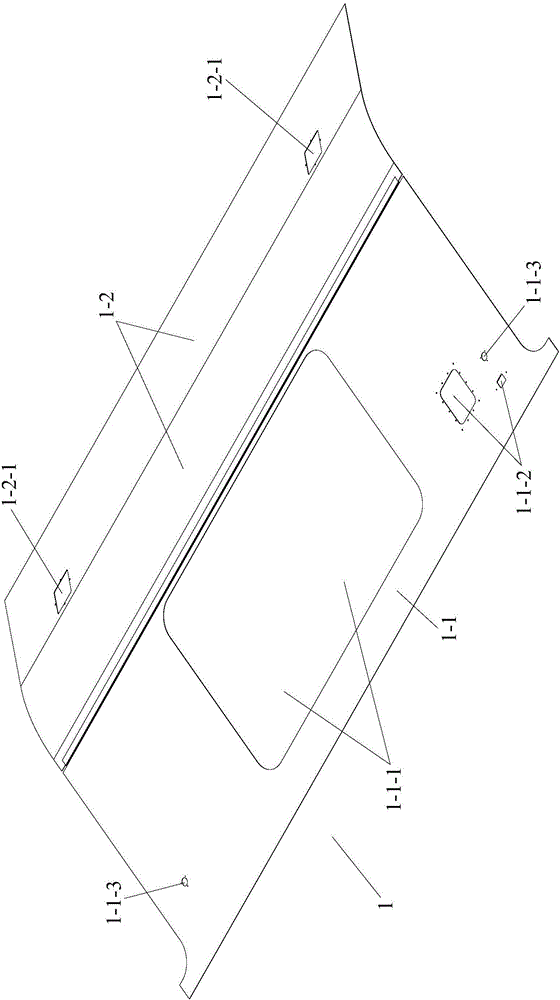

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 4 to Figure 9 As shown, the positioning and clamping tooling for laser welding stainless steel side walls of the present invention includes a table top 3 and a base 4. The shape of the table top 3 is the same as that of the curved surface profile of the side wall body 1, and the overall profile of the upper end surface of the base 4 is the same as that of the table top 3. The overall profile of the lower end surface matches, and the table top 3 is fixedly connected to the base 4 by bolts. The table top 3 is provided with a plurality of ventilation slots, and each ventilation slot is provided with at least one air extraction hole, and the table top 3 is provided with grooves around the positions corresponding to the openings on the side wall 1, and the grooves are filled with sealing rubber strips .

[0024] The table top 3 includes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com