A wiper with automatic adjustment of the pressing force of the scraping arm

A technology of automatic adjustment and pressing force, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc. It can solve the problems of insufficient bonding force between rubber strips and windshield glass, missing scratches and shaking, easy aging, etc., and achieves easy application The effect of promoting, suppressing deformation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

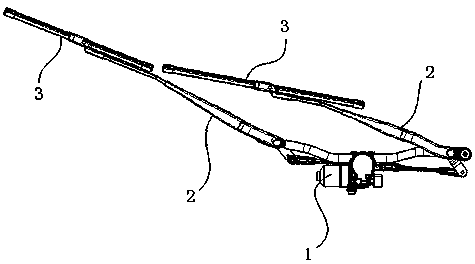

[0024] figure 2 It shows a wiper blade with automatic adjustment of the pressing force of the scraper arm, which includes a motor linkage rod assembly 1, a scraper arm 2 and a scraper 3, and the scraper arm 2 and the scraper 3 respectively have two scrapers 3 arranged on opposite sides. On the corresponding scraper arm 2, the motor linkage rod assembly 1 drives the scraper arm 2 to perform reciprocating circular motion around the output shaft.

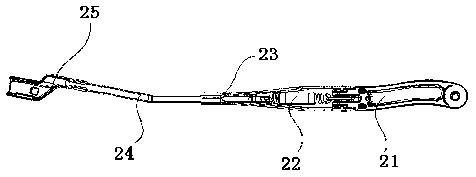

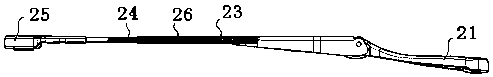

[0025] Such as image 3 and Figure 4 As shown, the scraper arm 2 includes a scraper head 21 , a main tension spring 22 , an extension arm 23 , a scraper rod 24 , a scraper connector 25 and a secondary compression spring 26 . One end of the extension arm 23 and one end of the scraping rod 24 are slidably connected together. The end of the scraping rod 24 is inserted into the extension arm 23 and a secondary compression spring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com