Isolation switch contact adjustment device

A technology of adjusting device and isolating switch, applied in electrical switches, electrical components, circuits, etc., can solve the problem of insufficient joint area of dynamic and static contacts of outdoor isolating switches, and achieve safe and reliable live operation, gentle action, and avoid hidden damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

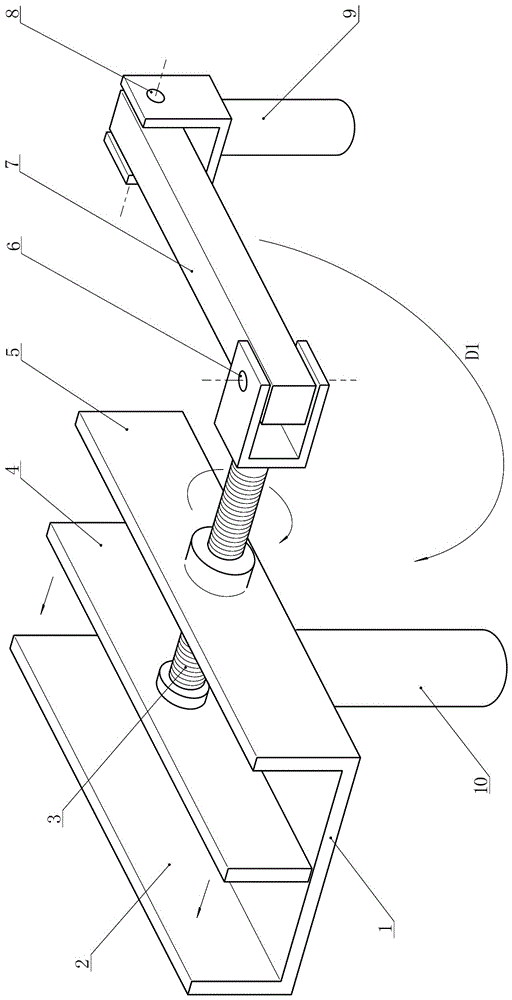

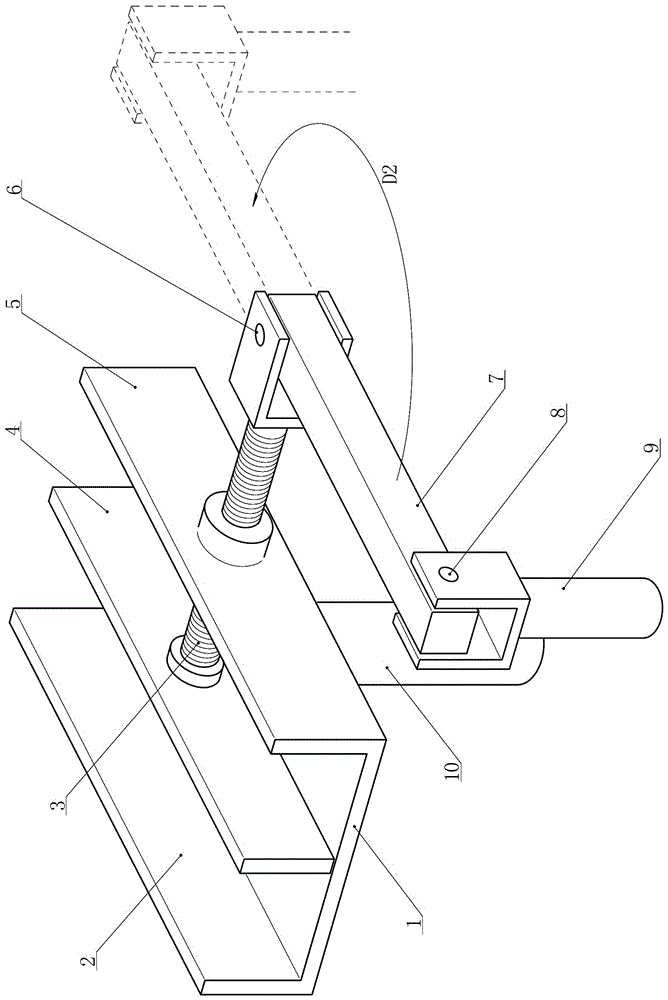

[0024] from Figure 1 ~ Figure 2 It can be seen that the present invention includes a clamping part and a transmission part;

[0025] The clamping part includes a clamping main body, a dynamic pressure plate 4 and a first connector 10 for connecting insulating rods; the clamping main body is composed of a bottom plate 1, a static pressure plate 2, and a side top plate 5; The lower edge is respectively connected with the two opposite sides of the bottom plate 1 to form a groove structure with the notch upward and both ends open; the dynamic pressure plate 4 is located in the notch of the clamping body, and is opposite to the static pressure plate 2 to form a bayonet; the first connector 10 is fixed on the lower part of the bottom plate 1 of the clamping main body.

[0026] The bottom plate 1, the static pressure plate 2, and the side top plate 5 are of an integral structure.

[0027] The transmission part includes a screw jack 3, a connecting rod 7 and a second connector 9 fo...

Embodiment 2

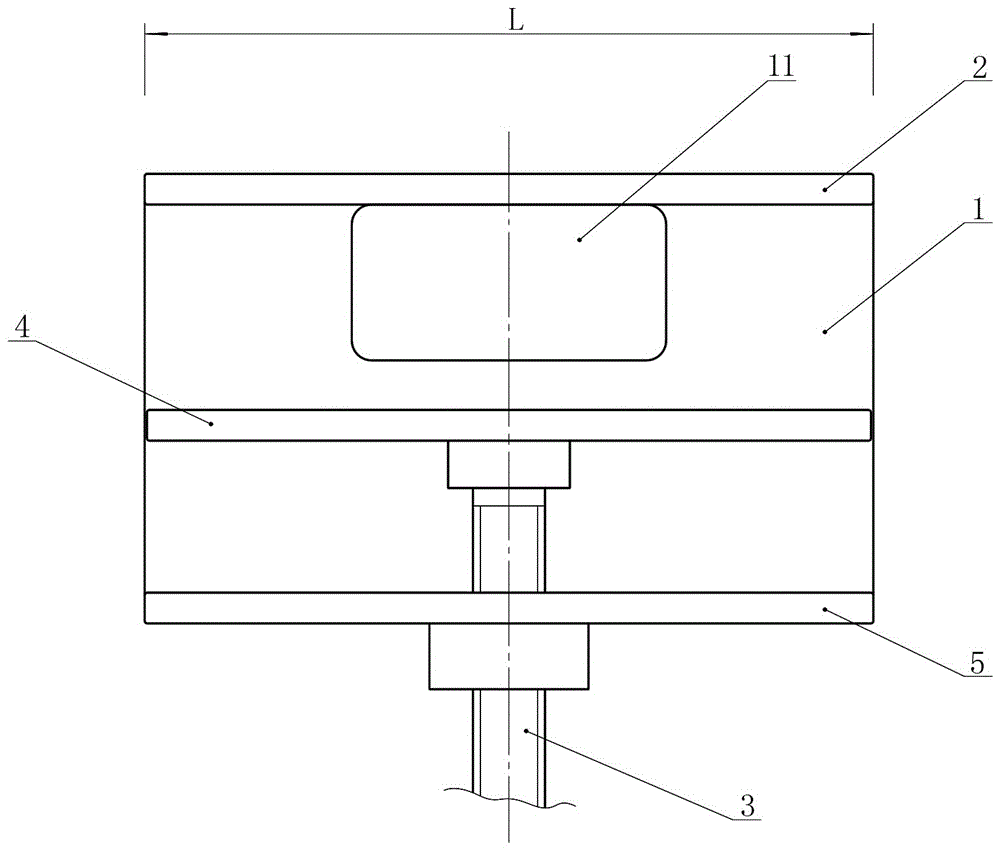

[0037] The difference between this embodiment and Embodiment 1 is that there is an observation port 11 on the side of the bottom plate 1 close to the static pressure plate 2, see image 3 , During the adjustment process of the isolating switch contacts, the staff is located below it and can observe the combination of the moving and static contacts at any time through the observation port 11. The lengths of the dynamic and static pressure plates are both 30cm; the end of the screw ejector rod located in the groove of the clamping main body is provided with a shoulder, and the shoulder is rotatably matched with the deck on the dynamic pressure plate.

[0038] Other technical features of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com