Stator assembly method and stator assembly device

An assembly method and stator technology, which are used in electromechanical devices, electric components, and prefabricated windings embedded in motors, etc., can solve the problems of increased insertion load, coil injury, and poor coil shape accuracy, and achieve the effect of suppressing the insertion load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, specific embodiments of the stator assembly method and the stator assembly device of the present invention will be described using the drawings.

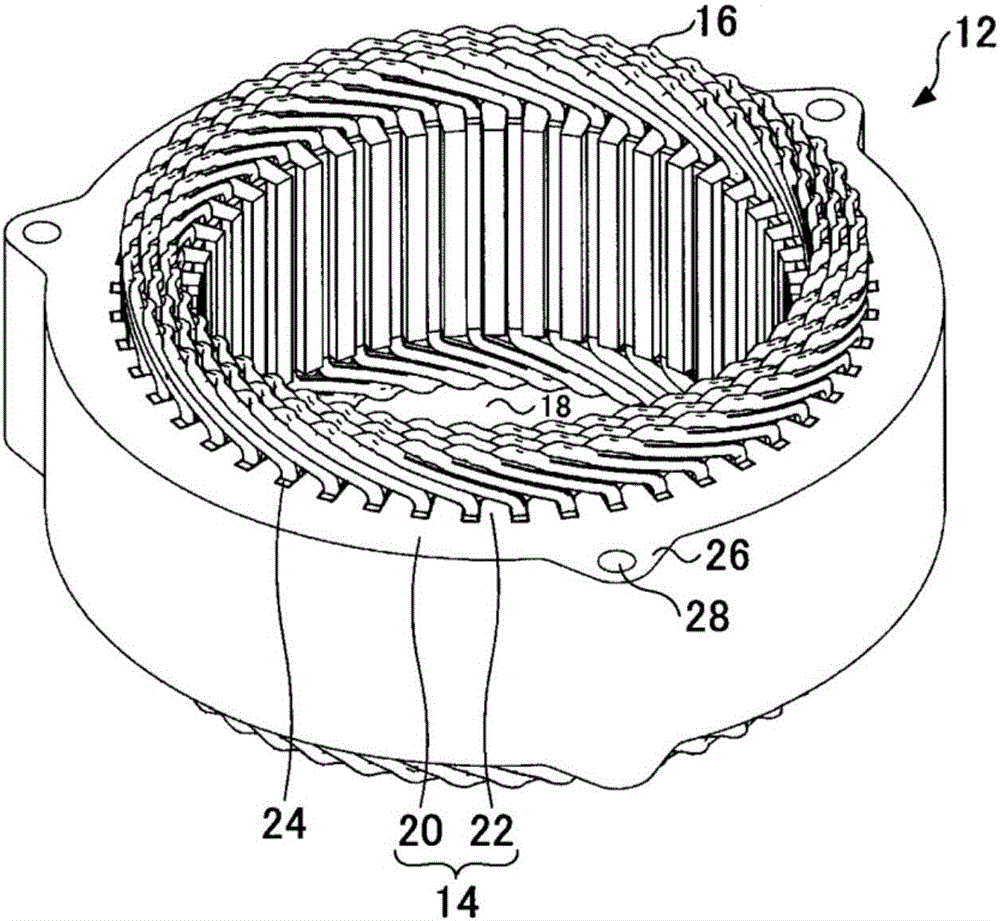

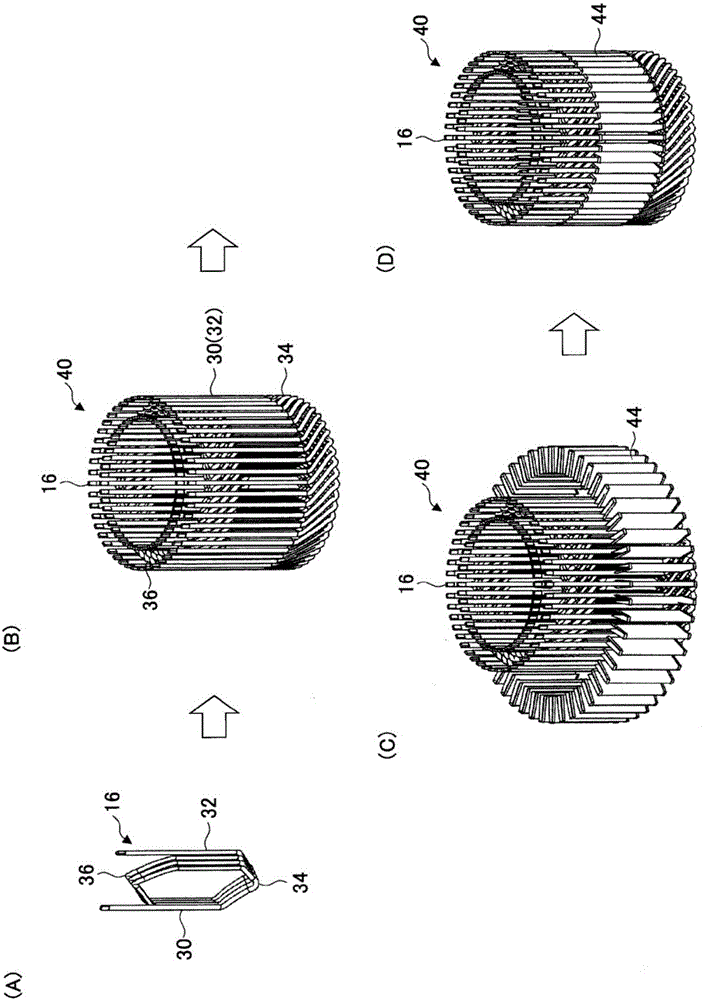

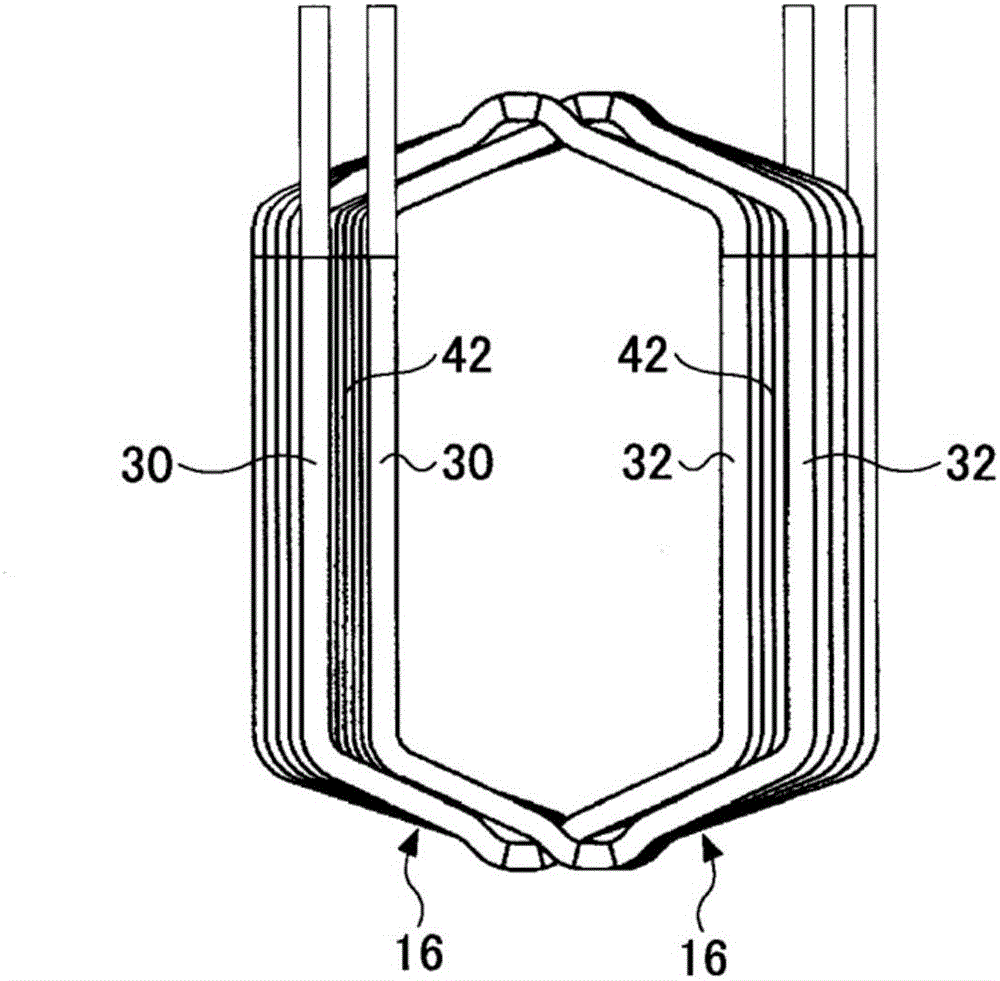

[0028] figure 1 It is a perspective view of a stator assembled using a stator assembling method and a stator assembling device according to an embodiment of the present invention. figure 2 It is a figure which shows the procedure which forms the coil assembly of the annular cage shape by several concentric windings in this Example. In addition, FIG. 3 is a diagram showing the positional relationship of two concentric windings of the same phase that accommodate the slot housing portion in the same slot in the present embodiment. In addition, FIG. 3(A) shows a view viewed from the shaft center side, and FIG. 3(B) shows a view viewed from the axial side.

[0029] The stator assembly device 10 of the present embodiment is a device for assembling the stator 12 which is a stator used in a rotating electric machine s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com