Device and method for generating biomass preparation

A biomass and microbial technology, applied in biochemical equipment and methods, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve problems such as poor effect, slow fermentation, and inability to achieve the effect of reducing electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

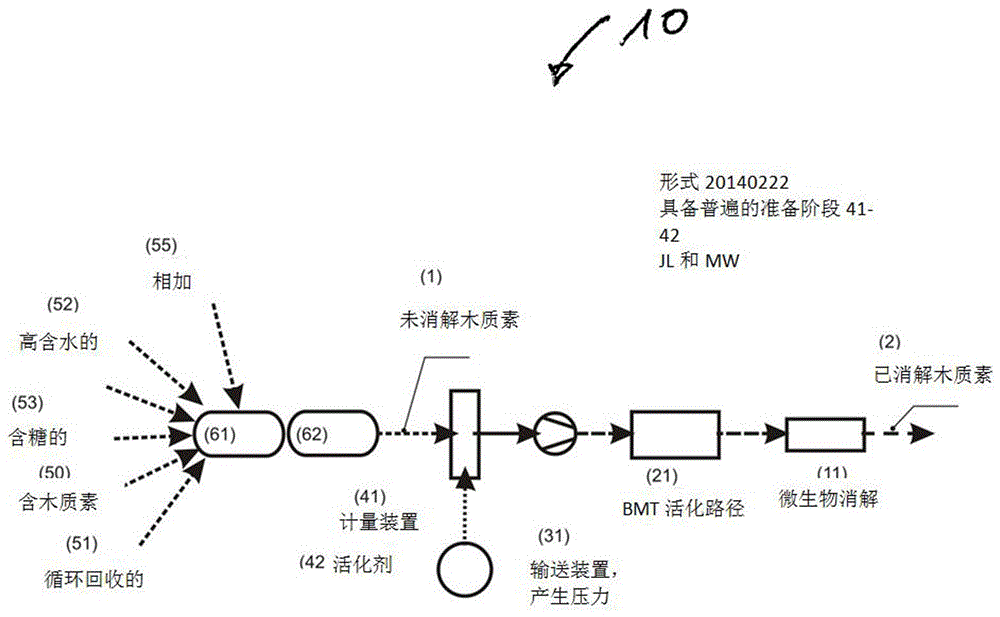

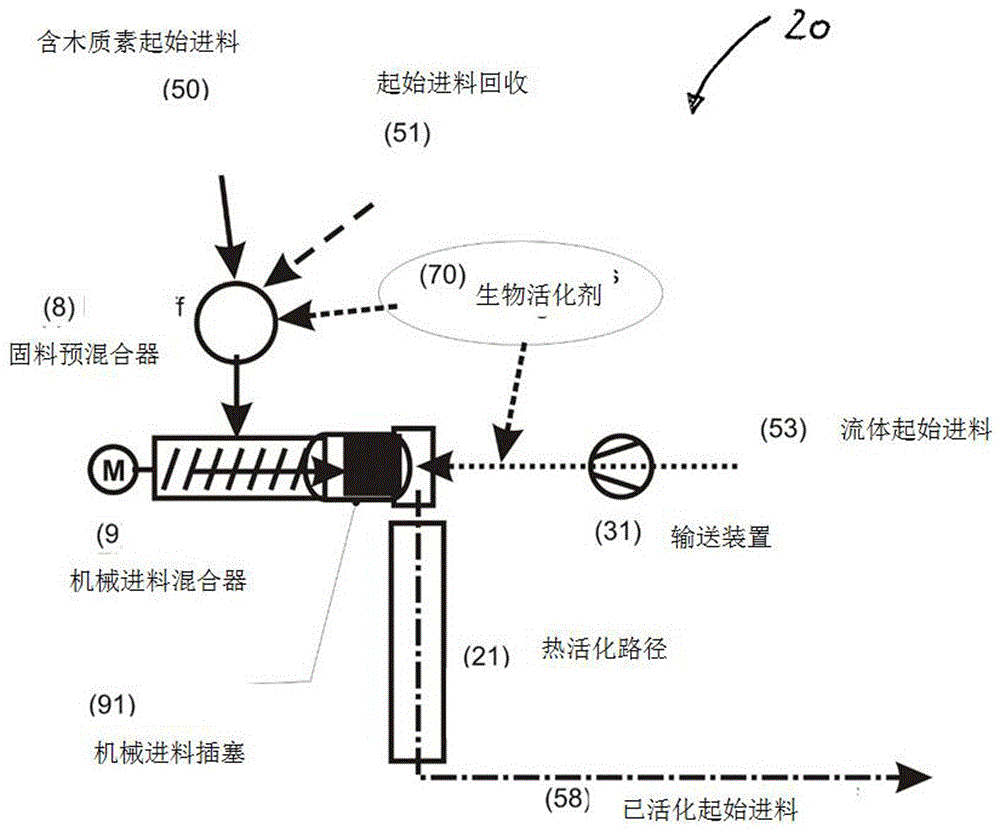

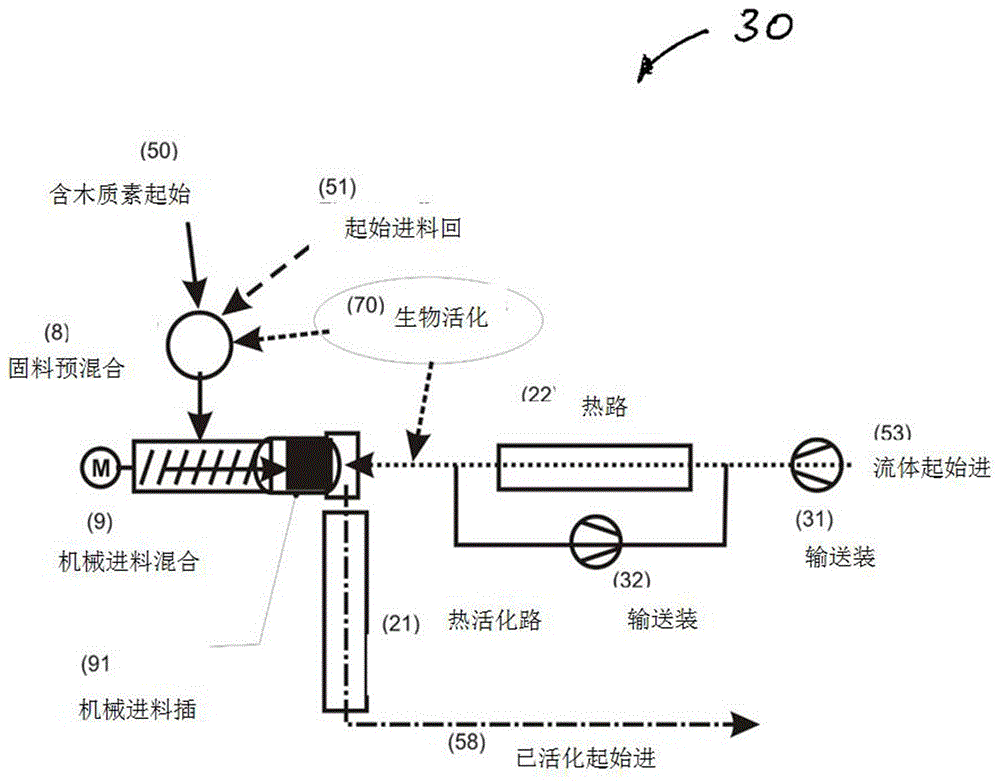

Method used

Image

Examples

example 1

[0132] With the repowering of the existing plant, the final repository starts to have a high solids feedstock content, the fermentation residue is removed from the final repository (1) and directed to the separator (2), whereby e.g. 25% is separated oTS solid component (51), and 4% oTS fluid component (52), the liquid separated by this separator is temporarily stored in the fluid container (3) of the separator, and heated for anti-frost if necessary.

[0133] This solid component ( 51 ) is also temporarily stored and if necessary conveyed to the inlet side of the solid mixer ( 8 ) for mixing with the input material. The 4% oTS fluid composition (52) is drawn from the storage vessel (3) by a pressure-generating pump (31) and compressed at a supply pressure of up to 5 bar.

[0134] The low-viscosity and chemically basic separator fluid (53) circulates with a slight pressure drop through a heat exchanger (21), where its heat is absorbed by a heated counterflow (57), which is heat...

example 2

[0143] In continuous operation, the biomass production obtained by the system according to the invention is almost completely available and recoverable in the fermenter; whereby, over several months, in the final repository (1) the organic solids content (TS or o (=organic)TS) drops below 4%, at which point the separator (2) is no longer needed and the final repository liquid can be used directly as a liquid feedstock (52).

example 3

[0145] As the starting material, dry straw should mainly be used, for example, for the following reasons, because dry straw is a garbage waste generated under large-scale agricultural operations, and in this case, the straw must be chopped; the TS content of straw is about 85% The treatment must be mixed with a liquid such as a fermentation broth, however, this leads to an increasingly high mineral content, and water is then added to this feed preparation and mixed with it to keep the fermenter from the mineral in the final repository. The concentration of the substance will not be too high for a long time.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap