A kind of single weft knitted fabric with horizontal strip effect and its preparation method

A weft-knitted fabric and single-sided technology, which is applied in weft-knitted knitting, fabric surface trimming, heating/cooling fabrics, etc., can solve the problems of poor transverse elasticity and extensibility, and single-sided fabric appearance, and achieve strong metal feeling and air permeability Good, rich effect on the fabric surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

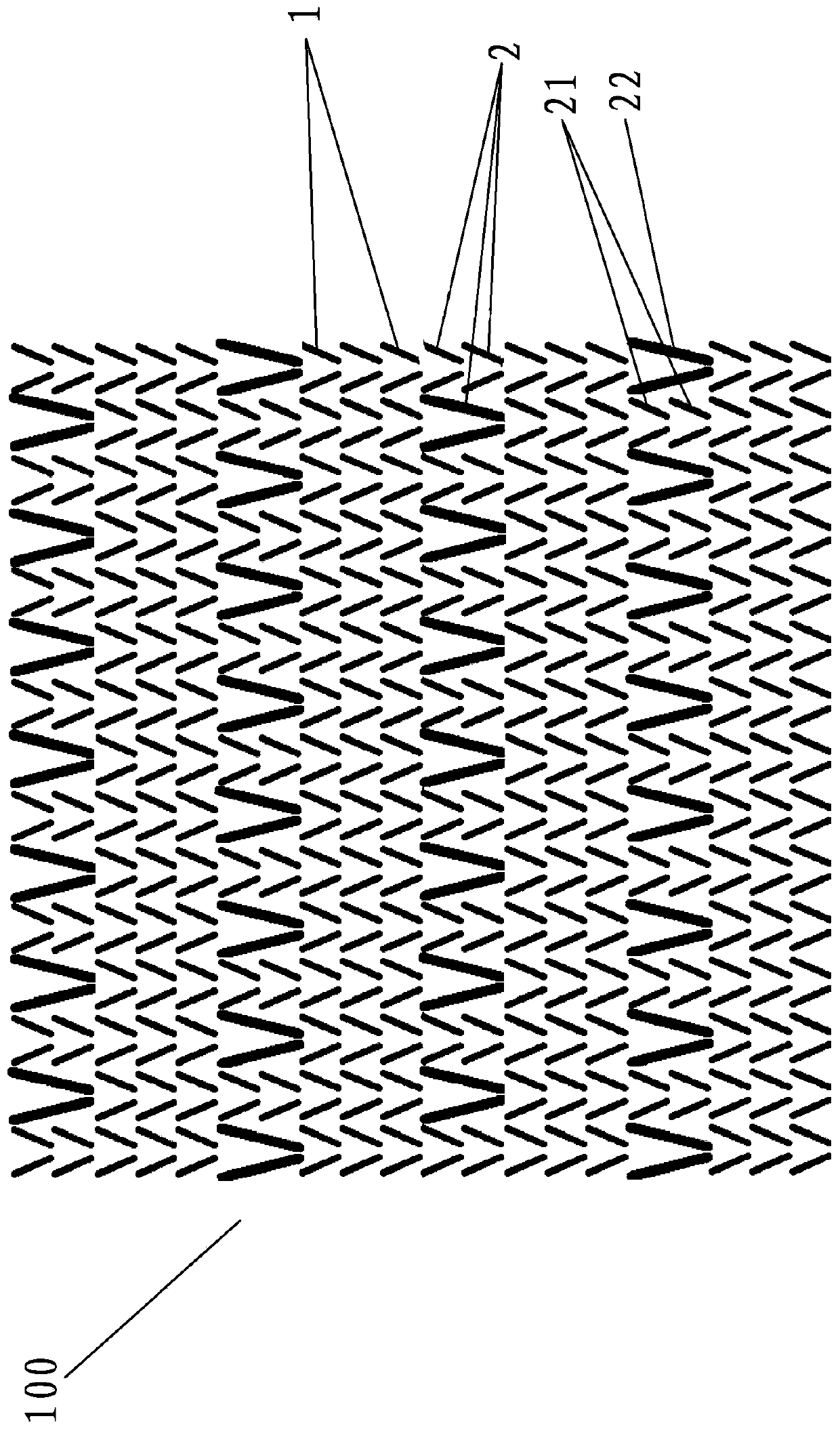

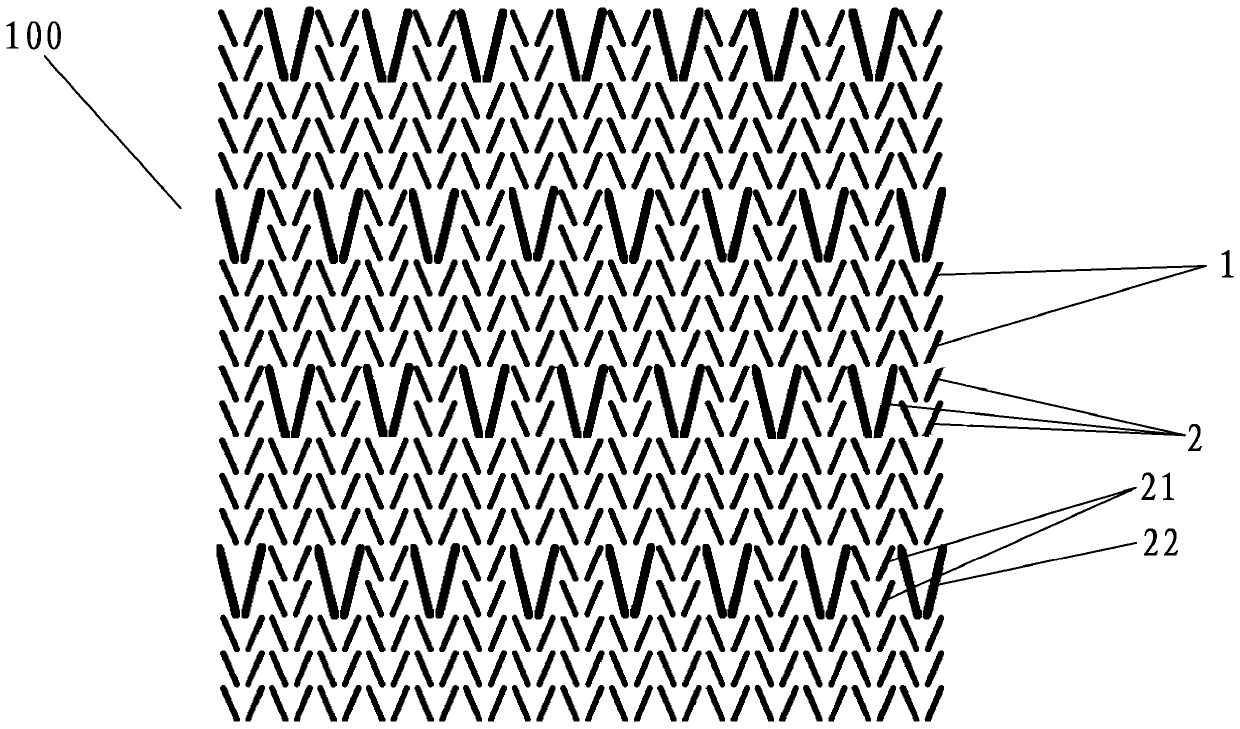

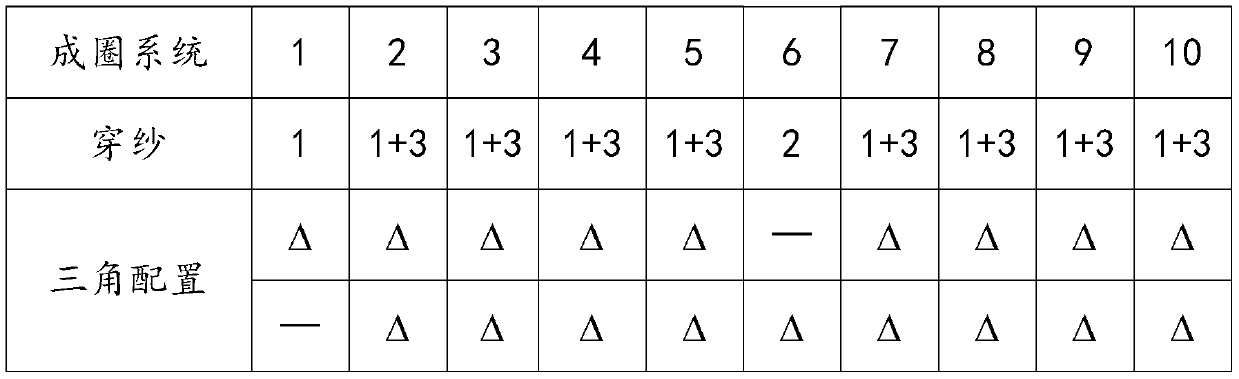

[0027] A single-jersey weft-knitted fabric with a horizontal stripe effect, such as figure 1 As shown, it includes a fabric body 100 with both front and back sides. The front side of the fabric body 100 has a horizontal stripe structure. The horizontal stripe structure is composed of a first stitch course 1 and a second stitch course 2. The first stitch course 1 and the second stitch course 2 are arranged alternately in the longitudinal direction, and the second course 2 after each first course 1 is displaced by 1 pitch, that is, in figure 1 Among them, several first courses 1 and second courses 2 are provided, and each first course 1 and each second course 2 are closely arranged together along the up and down direction of the fabric body 100, and the two first courses There is a second course 2 between the 1, preferably: the first course 1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com