Manual threading die rack with adjustable steel bar diameter and application method

A die frame and steel bar technology, applied in metal processing equipment, thread cutting devices, manufacturing tools, etc., can solve the problems of complicated preparation work, difficult implementation, slow implementation speed, etc., to achieve convenient and fast threading, fast, convenient and flexible operation, Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

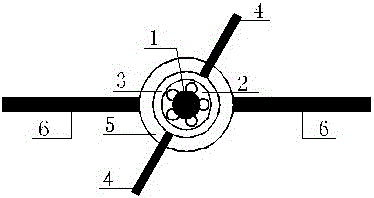

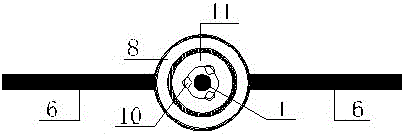

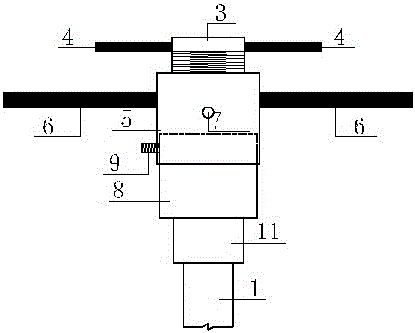

[0017] Such as figure 1 As shown, the present invention is an adjustable steel bar diameter manual die holder and a method of use thereof. The adjustable steel bar diameter manual die holder includes a steel bar 1, a die 2, a die lock 3, a lock handle 4, a die holder 5, a die holder handle 6, and a die Set screw 7, rotator 8, rotator set screw 9, expander 10, expander matrix 11, put the die 2 matching the diameter of the steel bar 1 into the die holder 5 slot, and fix the die 2 with the die set screw 7, The lock handle 4 used to rotate the die lock 3 locks the die 2 in the groove of the die holder 5, the steel bar 1 is placed in the telescopic matrix 11, and the telescopic device 10 used to occlude and fix the steel bar 1 is a three-claw with a built-in slideway Conical cylinder, used to fix the expander body 11 of the expander 10. The position of the three claws of the expander 10 can be adjusted by stretching. By turning the rotator 8, the steel bar 1 can be bitten by the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap