Reinforcement diameter-nonadjustable center arrangement manual die handle and application method

A die frame and steel bar technology, applied in metal processing equipment, tangent devices, manufacturing tools, etc., can solve the problems of complicated preparation, slow implementation, difficult implementation, etc., and achieve low price, convenient use, fast, convenient and flexible operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

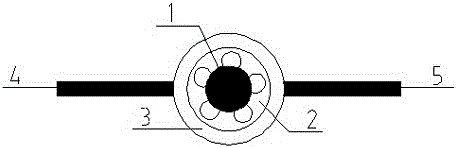

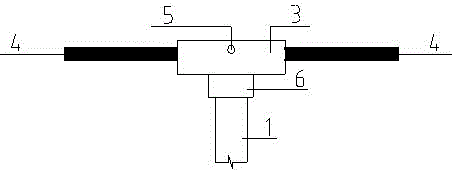

[0015] like figure 1 , figure 2 As shown, the present invention is a non-adjustable steel bar diameter manual die holder and a method of use. The non-adjustable steel bar diameter manual die holder includes a steel bar 1, a die 2, a die holder 3, a handle 4, a die positioning pin 5, and a manual die holder. Convex edge 6, put the die 2 into the slot of the die holder 3, fix the die 2 with the die positioning pin 5, connect the handle 4 with the die holder 3, insert the steel bar 1 into the die holder 3 through the convex edge 6, and rotate The handle 4 is threaded on the steel bar 1 .

[0016] The diameter of the non-adjustable steel bar mentioned above is reasonable manual die frame, the steel bar 1 can be a smooth steel bar, or a threaded steel bar, or a crescent rib steel bar; the diameter of the steel bar 1 is determined according to the actual project, and the diameter of the steel bar 1 when threading each time is Fixed and non-adjustable; the diameter of steel bar 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap