Method of manufacturing steel plate for high-heat input welding

A technology of large energy input welding and manufacturing method, which is applied in the field of manufacturing steel plates for high input energy welding, which can solve the problems that it is difficult to fully suppress the growth of austenite grains in HAZ, difficulties, and the reduction of HAZ toughness, and achieve excellent joint characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

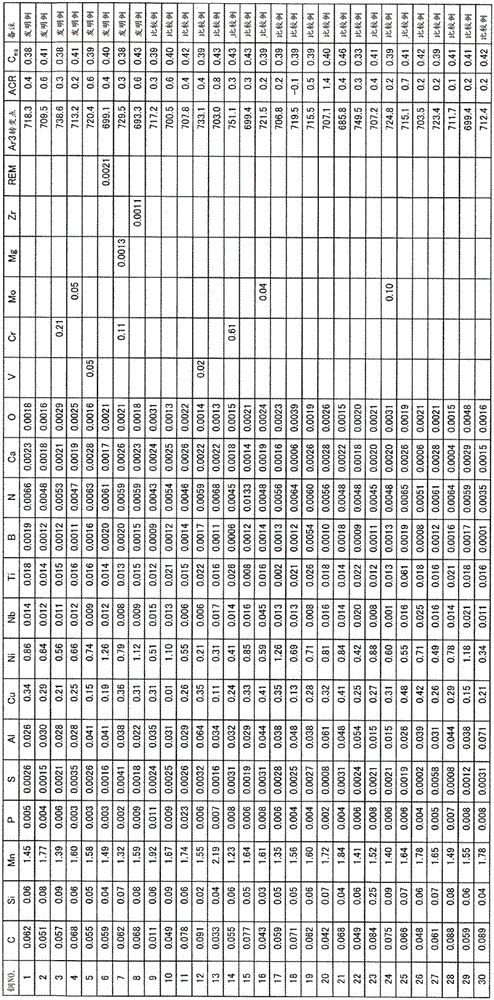

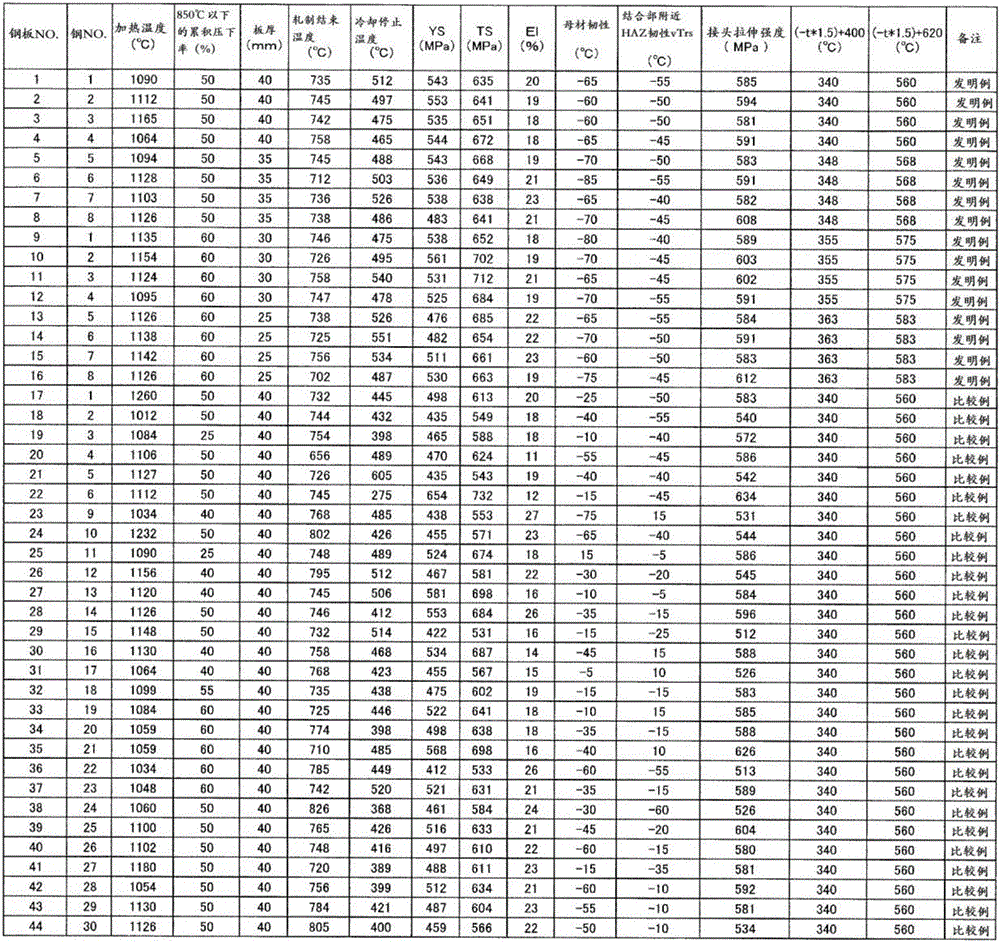

[0110] Next, examples made by the present inventors will be described.

[0111] First, using a 150 kg high-frequency melting furnace, molten steels of Nos. 1 to 23 having the component compositions shown in Table 1 were respectively melted and cast to manufacture ingots (steel materials). Next, steel sheets of various thicknesses are produced by hot-rolling each steel ingot. Further, the obtained steel sheet was subjected to rolling and accelerated cooling under various rolling and accelerated cooling conditions to produce a steel sheet having a thickness of 25 mm or more and less than 50 mm. Then, the test piece No. 1A described in JISZ2201 was collected from each steel sheet so that the longitudinal direction and the sheet width direction were aligned, and the yield stress YS (MPa), tensile strength TS (MPa), and total elongation El (%) were measured. In addition, in Table 1, Steel Nos. 1 to 8 are examples of the present invention, and Steel Nos. 9 to 23 are comparative exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com