Gun smart safety trigger lock

A trigger lock and gun technology, applied in the field of trigger locks, can solve the problems of user danger, complicated unlocking operation, and long time consumption, and achieve the effects of reasonable structure setting, convenient and quick unlocking, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

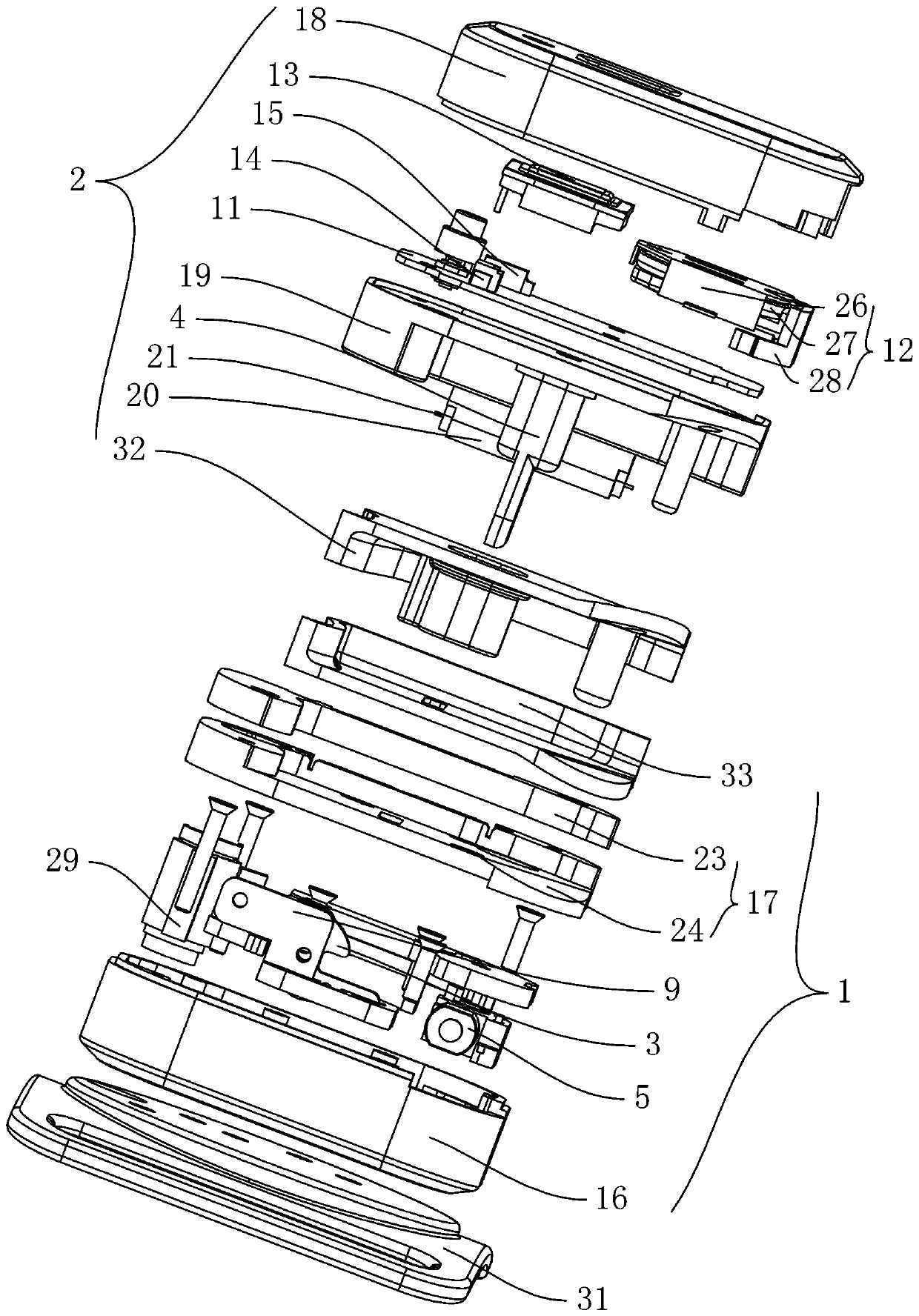

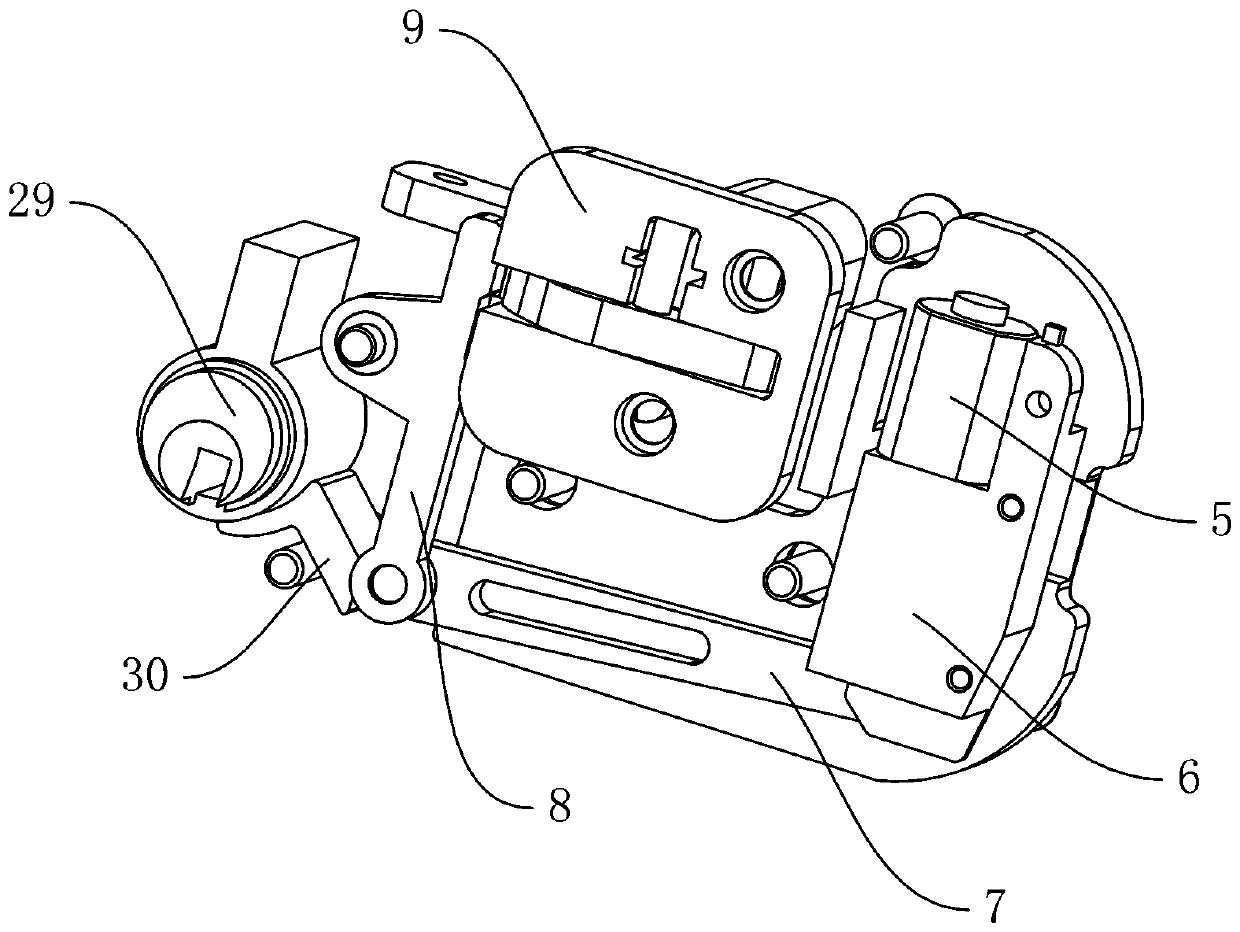

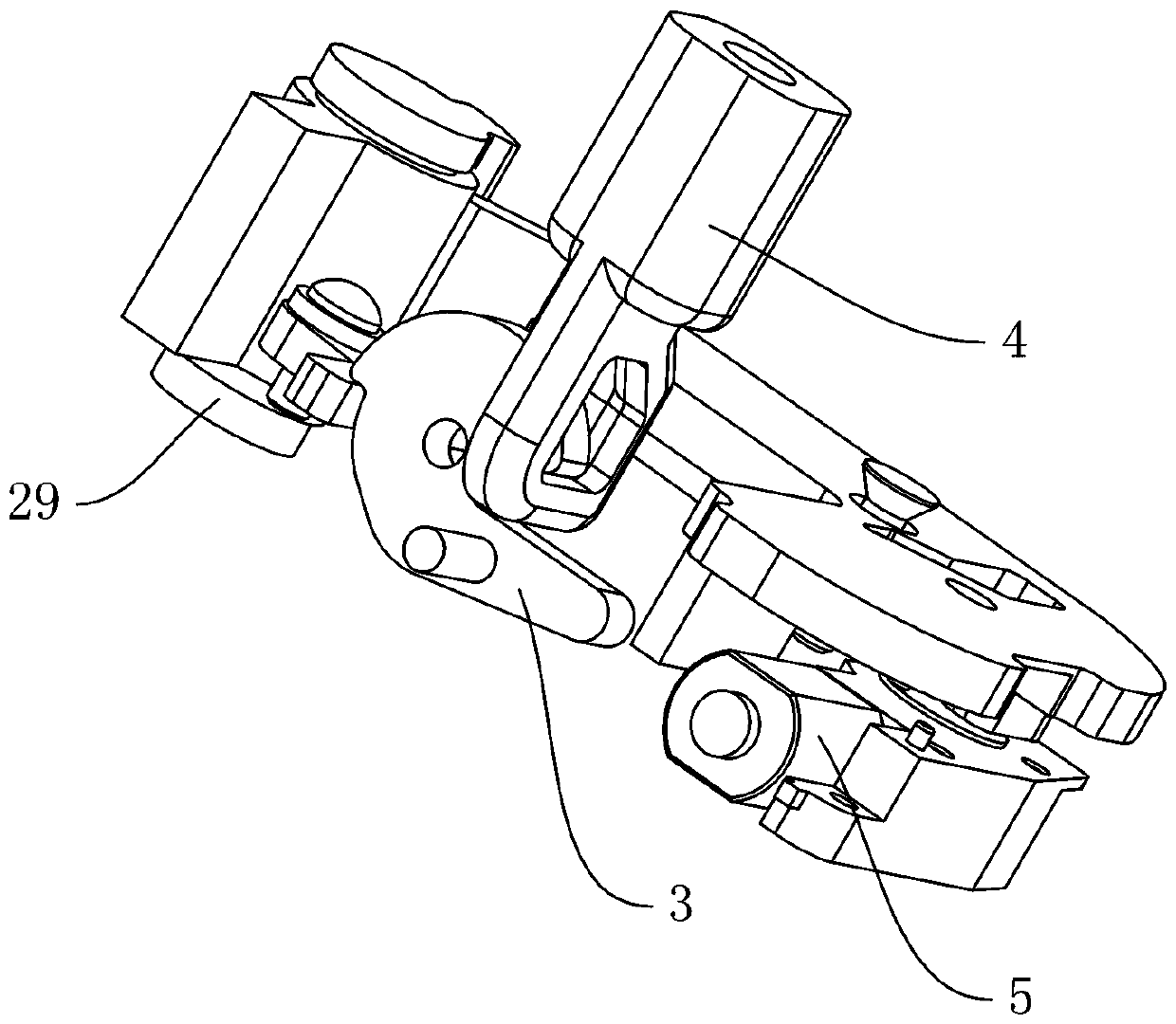

[0025] Such as Figure 1 to Figure 6 As shown, the gun intelligent safety trigger lock according to the present invention includes a left lock base 1 and a right lock base 2 which are interlocked with each other. After the left lock base 1 and the right lock base 2 are locked, they can be fixedly placed in the trigger position of the gun. , the left lock seat 1 is hinged with the side of the right lock seat 2, the left lock seat 1 includes a lock hook 3 and a locking mechanism that drives the lock hook 3 to operate, and the right lock seat 2 includes a lock catch 4 that cooperates with the lock hook 3 and controls the locking The main control module of the mechanism operation, the lock catch 4 is fixedly arranged on the side adjacent to the left lock base 1 of the right lock base 2; the locking mechanism includes a motor 5, a worm gear mechanism 6, a first Connecting ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap