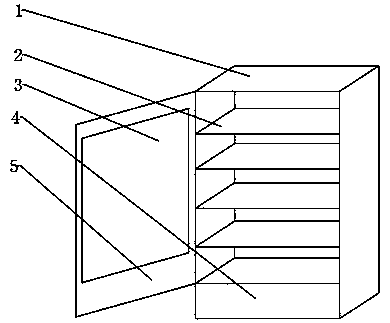

An electronic product aging test device

An aging test and electronic product technology, which is applied in the direction of measuring device, measuring electricity, measuring electrical variable, etc., can solve the problem that the aging test time and temperature control are prone to errors, the utilization rate of the aging test device is low, the site use of the aging test device, and the equipment Issues such as adverse effects of maintenance safety management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

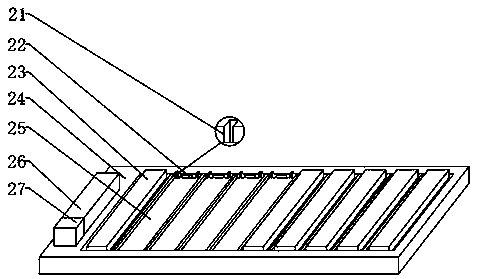

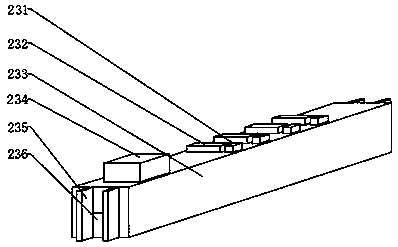

[0027]Specific embodiments: each detection interface 232 is connected in series with its corresponding indicator light 231 to form a small whole, and each small whole is connected together through a parallel circuit, and then connected with the variable resistor 234 through a series circuit, and the operator will The electronic components are connected to the detection interface 232, and the variable resistor 234 is adjusted to a suitable position to meet the voltage requirements of the electronic components. This design can ensure that each electronic component can independently carry out the aging test, and any problem with any electronic component can be repaired in time. It is found and does not affect other electronic components to continue to work.

[0028] The operator places the variable voltage detection board 23 on the upper end of the connection groove 25 through the fitting connection between the connection protrusion 235 and the positioning groove 21, the metal con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com