Tire uniformity tester and tire uniformity measurement method

一种均匀性、试验机的技术,应用在汽车轮胎测试、轮胎安装、轮胎零部件等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

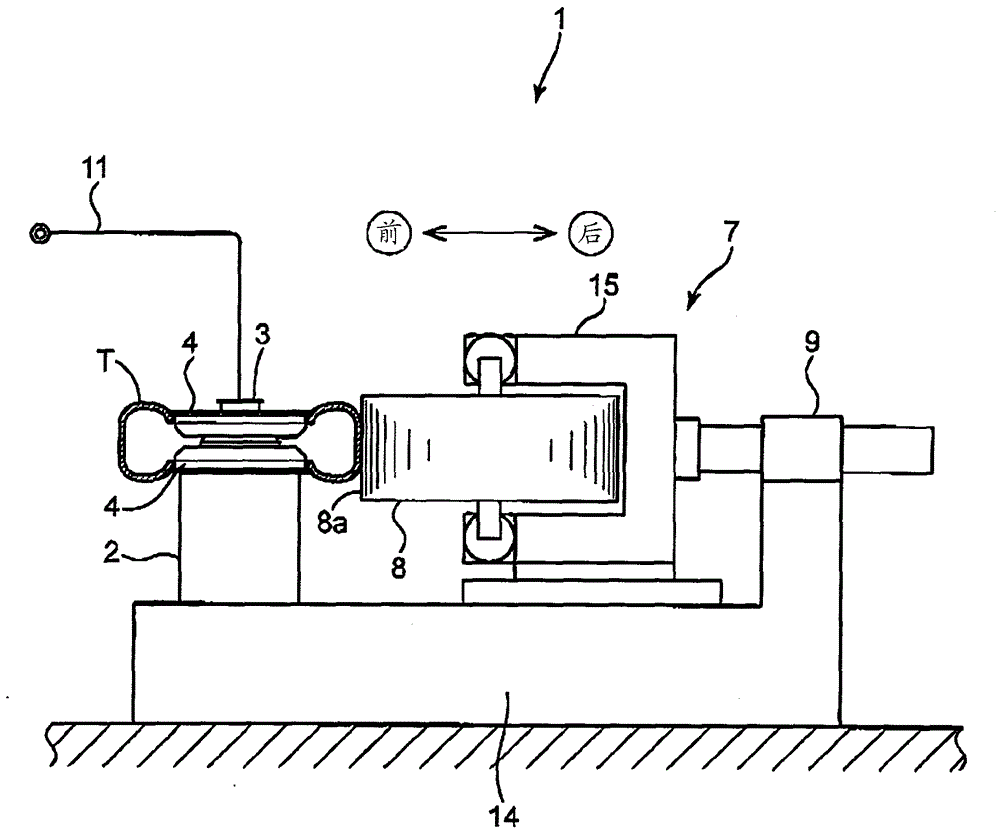

[0015] A tire uniformity testing machine and a tire uniformity measuring method according to an embodiment of the present invention will be described based on the drawings. figure 1 and figure 2 The tire uniformity testing machine 1 of the aforementioned embodiment is shown, and the "up and down direction" of the testing machine 1 described below corresponds to figure 1 The up-down direction of the paper, and the "front-back direction" corresponds to the left-right direction of the paper.

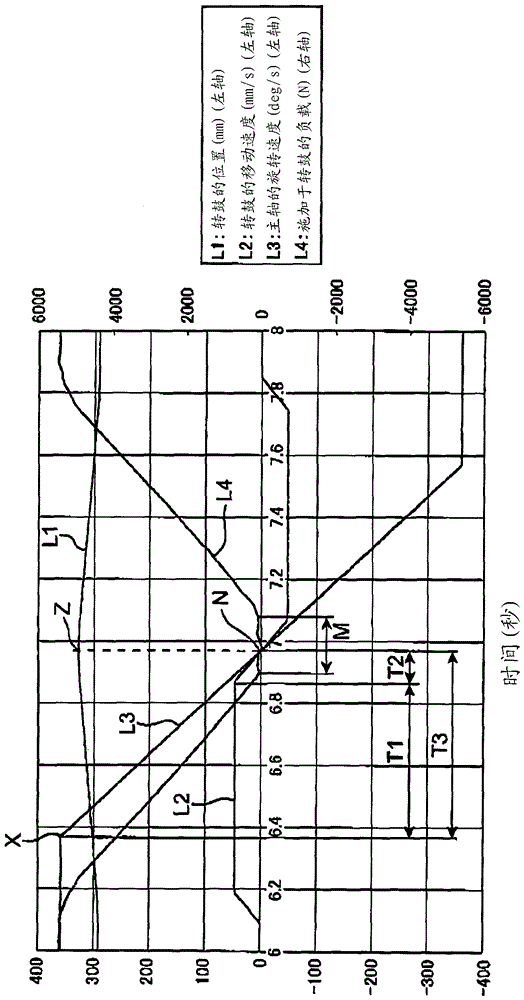

[0016] The aforementioned tire uniformity testing machine 1 (hereinafter also referred to simply as a tire testing machine) is used as a finished product inspection to evaluate the tire uniformity characteristics of the finished tire T, especially the variation of the longitudinal force of the tire T (Radial ForceVariation: RFV), lateral force variation of the tire T (Lateral Force Variation: LFV), and taper force (conicity) (a lateral force always generated in a certain direction regardl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com