A method for forming an internal high-pressure forming die for forming a stepped pipe fitting

A technology of internal high-pressure forming and stepped structure, which is applied in the field of plastic forming of pipe fittings, can solve the problems of increased forming pressure of sharp-edged structures, increased friction between pipes and molds, and equipment that cannot meet the requirements, so as to reduce production costs and reduce friction. Small, avoiding the effect of excessive thinning and cracking of wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

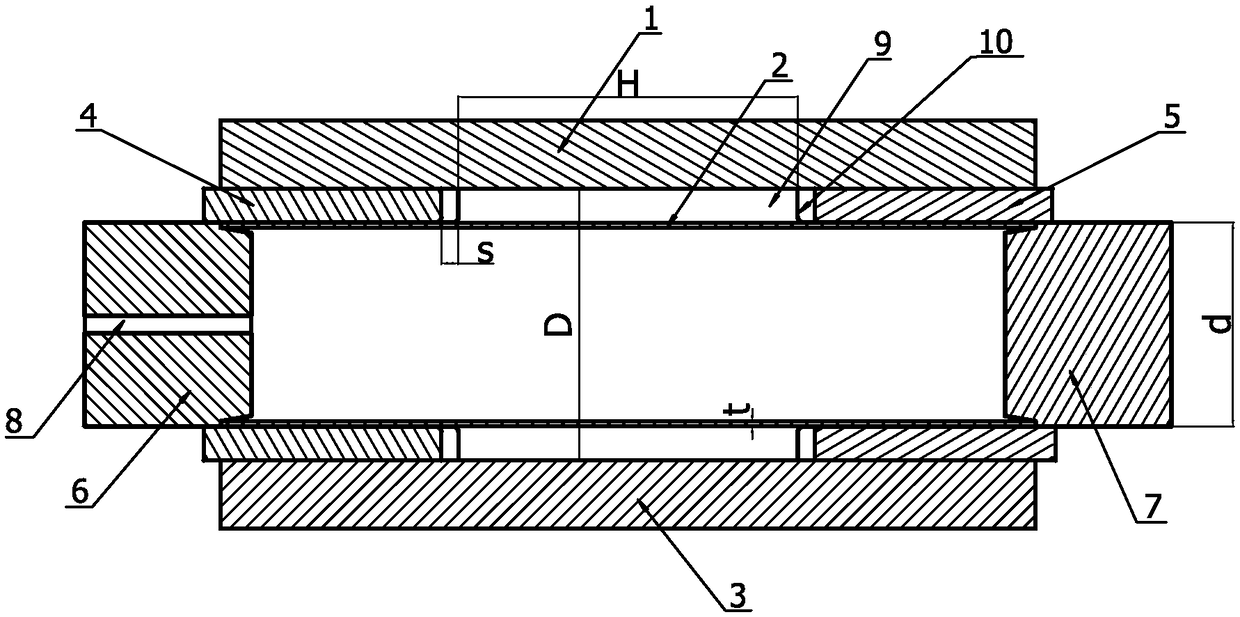

[0042] Embodiment 1: as figure 1 As shown, the formed pipe fitting is a variable-diameter straight pipe bulging pipe fitting. The material of pipe 2 is DC04, the diameter is 60mm, the thickness is 1.5mm, the diameter of the middle bulging part is 80mm, and the length is 100mm.

[0043]The traditional internal high pressure forming die is adopted, the forming pressure is 120MPa, the left and right feed is 18mm, and the loading path is linear loading. The pipe fitting 9 formed by the internal high pressure forming process has a minimum radius of 8 mm, a minimum wall thickness of 1.036 mm, and a thinning rate of 30%.

[0044] The test piece is formed by using the internal high pressure forming mold for forming a stepped pipe fitting of the present invention, the distance s between the left and right bushings and the side wall 10 of the pipe cavity is 3 mm, the loading path is the same as that of the traditional internal high pressure forming mold, and the internal pressure only ...

Embodiment 2

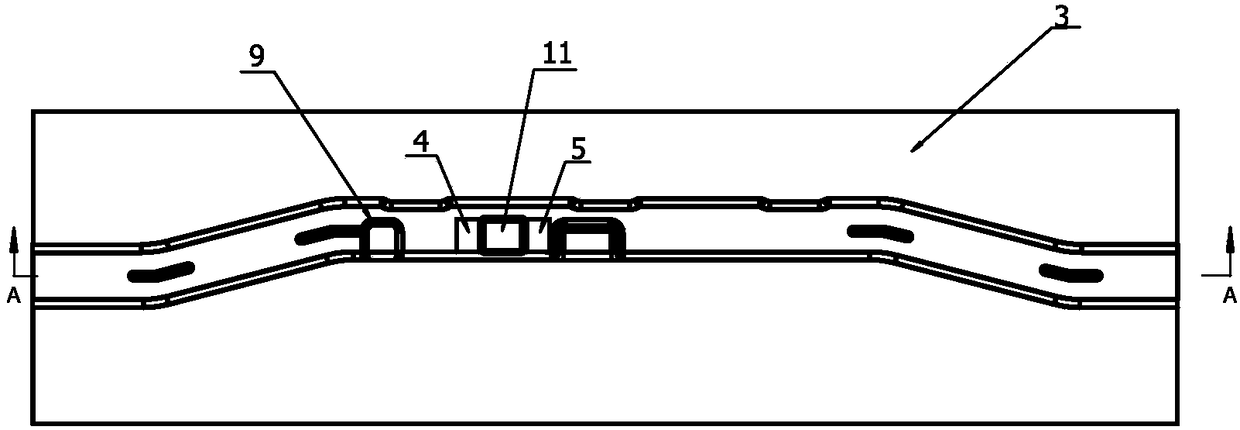

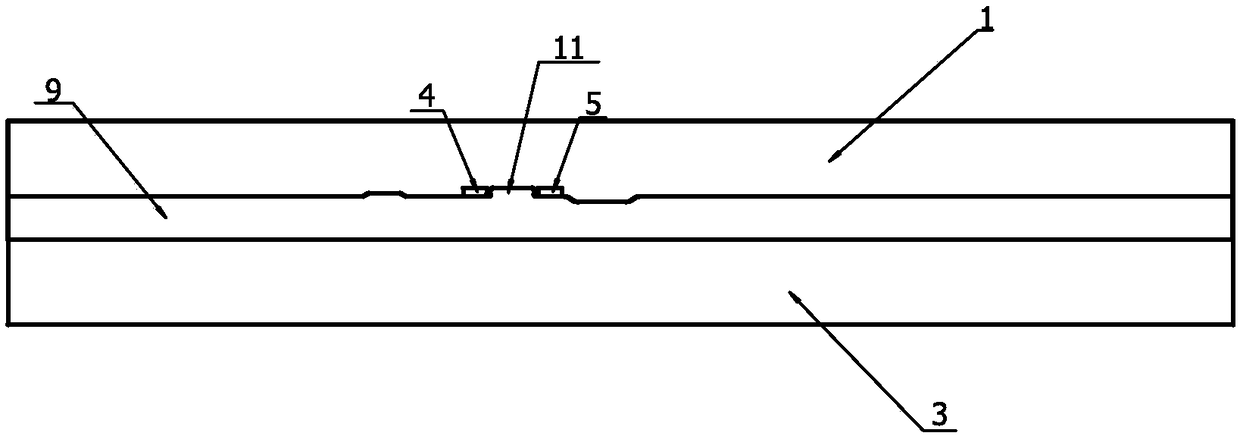

[0045] Embodiment 2: as Figure 2-3 As shown, the formed pipe fitting is a bulging type pipe fitting with a complex axis. The material of the pipe 2 is DC04, the diameter is 56mm, the thickness is 1.5mm, the height of the middle forming boss 11 is 10mm, and the length is 50mm.

[0046] The traditional internal high pressure forming die is adopted, the forming pressure is 150MPa, the left and right feed is 18mm, and the loading path is linear loading. The pipe fitting 9 formed by the internal high pressure forming process has a minimum radius of 4.5 mm, a minimum wall thickness of 0.959 mm, and a thinning rate of 36.1%.

[0047] The test piece is formed by using the internal high pressure forming mold of the stepped structure pipe fitting of the present invention, the distance s between the left and right bushings and the pipe cavity side wall 10 is 4mm, the loading path is the same as that of the traditional internal high pressure forming mold, and the internal pressure only n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com