Combination forming method of deep drawing-punching with variable blank-holding force for tapered foil plate

A technology of variable blank holder force and composite forming, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of types of materials that are easy to pollute the environment, insufficient process stability, long processing cycles, etc., to reduce wall thickness and reduce The effect of thinning, improving the drawing ratio, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

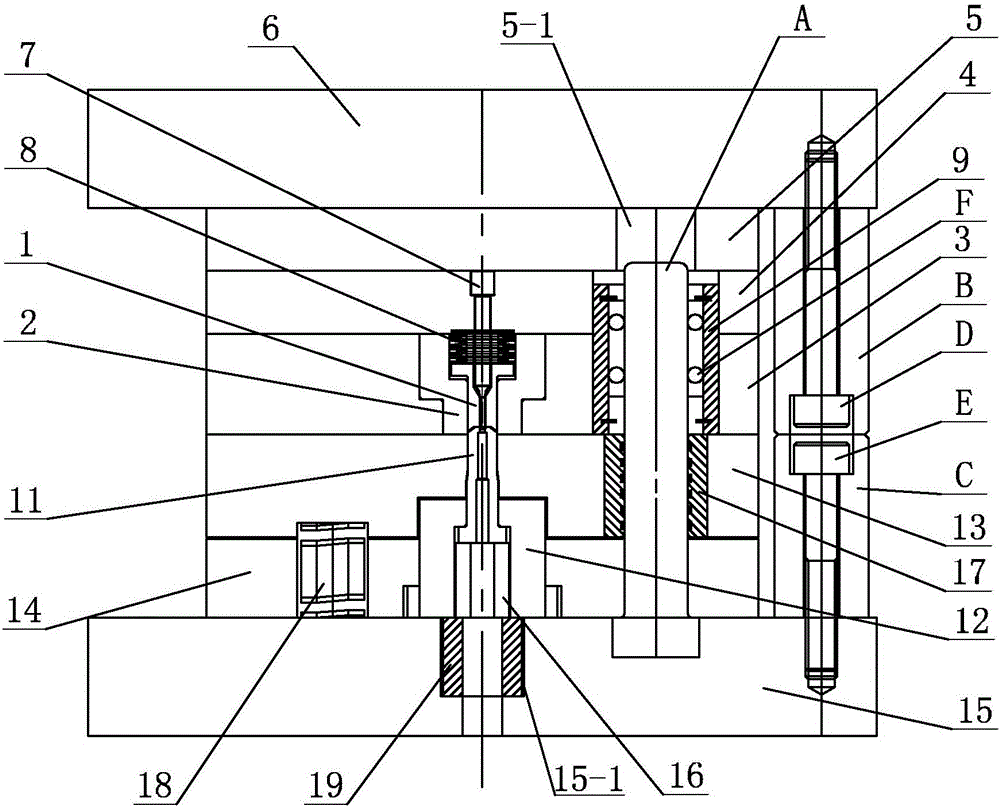

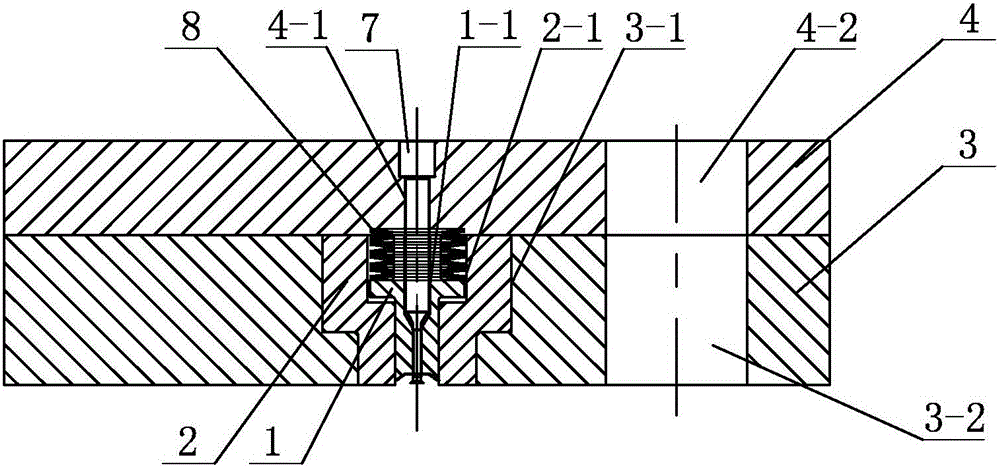

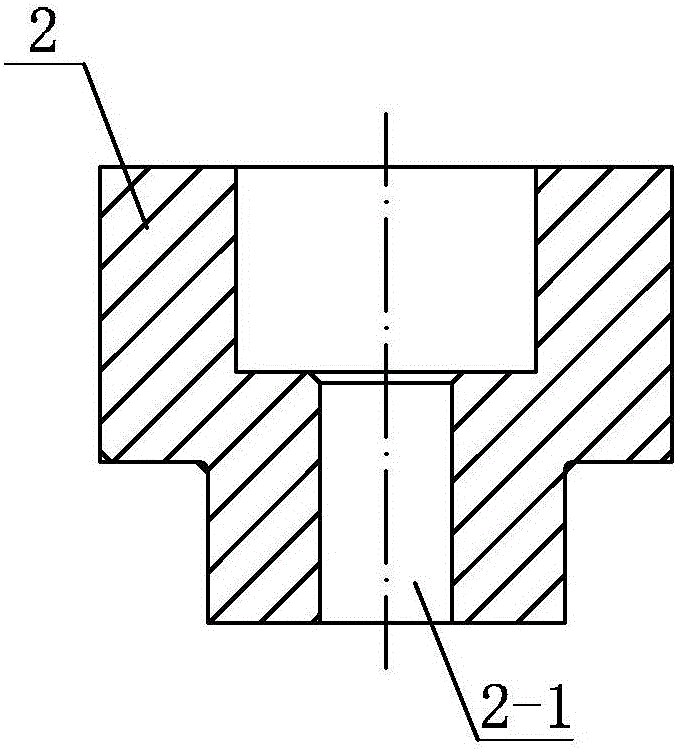

[0032] Specific implementation mode one: combine Figure 1 to Figure 11 Describe this embodiment, this embodiment includes upper mold, lower mold, guide post A, upper limit body B, lower limit body C, upper bolt D and lower bolt E, upper mold includes upper die 1, upper die fixing block 2. Upper binder ring 3, upper die fixing plate 4, upper template 5, upper die seat 6, punch 7, first spring 8 and upper die guide sleeve 9, upper and lower end surfaces of upper binder ring 3 are provided with The mounting hole 3-1 of the upper die fixing block and the first hole 3-2 of the guide sleeve, the upper die fixing block 2 is embedded in the mounting hole 3-1 of the upper die fixing block, the upper and lower end faces of the upper die fixing block 2 There is an upper die mounting hole 2-1, see image 3 , the upper die 1 is set in the upper die mounting hole 2-1, and the upper die 1 is provided with a punch hole 1-1 along the upper and lower end faces, see Figure 4 , the punch hole...

specific Embodiment approach 2

[0033] Specific implementation mode two: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that it also adds several balls F, and several balls F are arranged between the guide post A and the upper die guide sleeve 9 . The ball E plays a supporting role. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0034] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and the specific embodiment one or two is that it also has a second spring 18, the lower end surface of the lower binder ring 13 is provided with a blind hole 13-4, and the lower punch fixing plate 14 There is a second spring installation hole 14-3 facing the blind hole 13-4, and the second spring 18 is installed in the blind hole 13-4 and the second spring installation hole 14-3. The second spring 18 plays a role in providing force for the blank holder in the later stage of deep drawing, and in addition, provides force for the blank holder during blanking. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com