Differential temperature drawing process method

A process method, a technology of differential temperature deep drawing, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of energy waste, low heating efficiency, etc., and achieve the effect of improving heating efficiency, improving production efficiency, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Such as Figure 1-7 As shown, if you want to carry out differential temperature deep drawing on a cylindrical part, the steps are as follows:

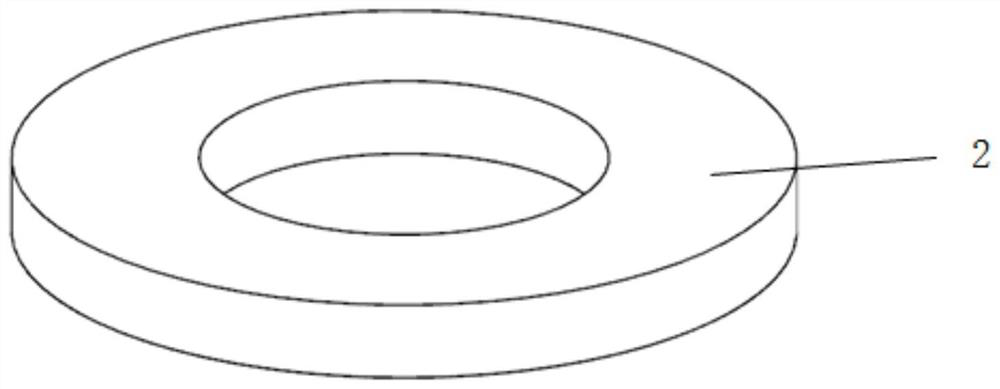

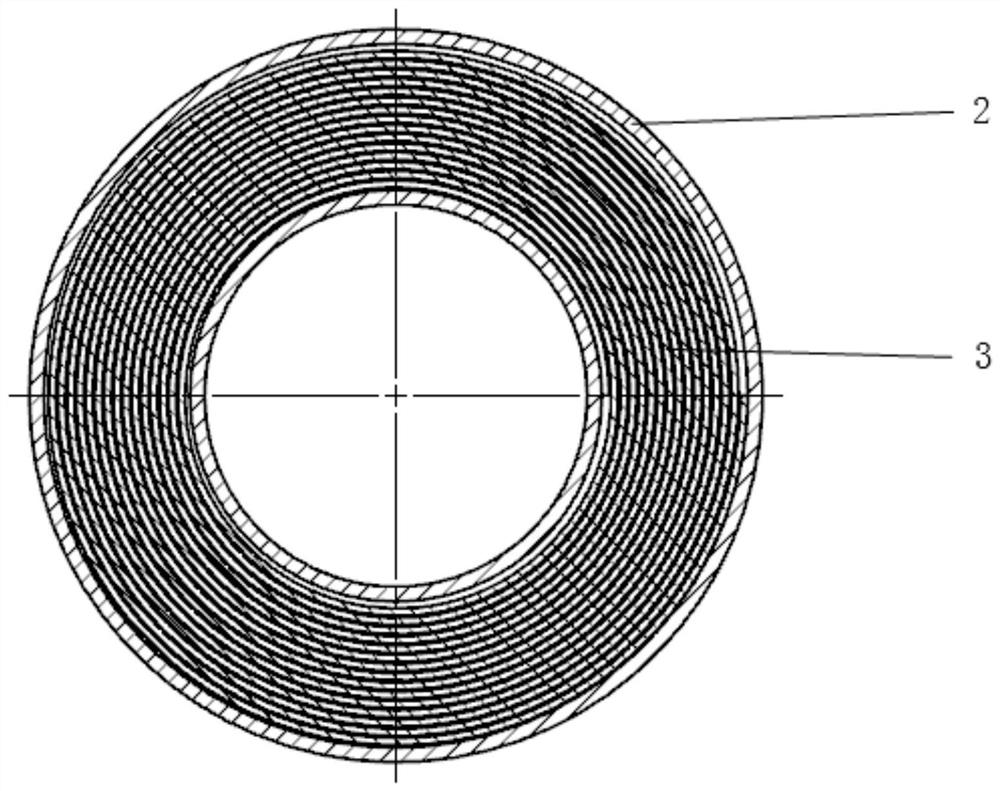

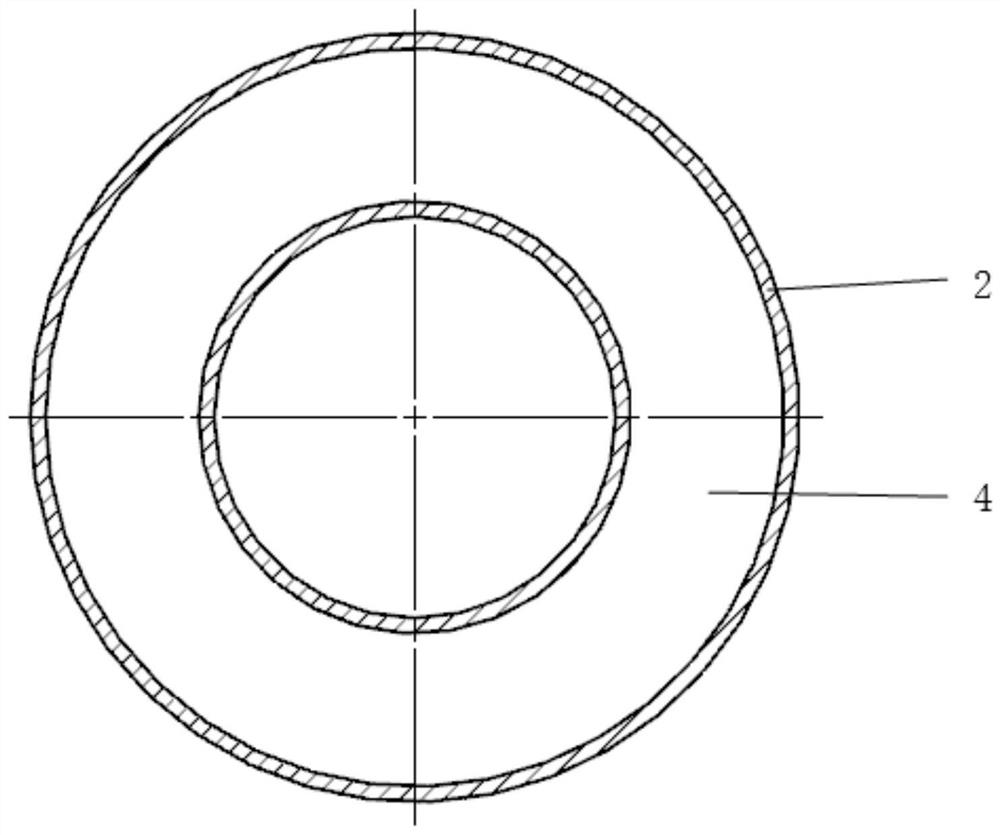

[0035] S1. Ceramics will not shield the magnetic field, and they will not be heated by induction. Moreover, the strength of some special ceramics can reach 40-100Mpa, and the blankholder force is often within 30Mpa. Therefore, the ring-shaped blankholder 2 of ceramic material is selected; the blankholder 2 A circular cavity 4 is arranged inside, and coils 3 at equal intervals are wound in the cavity 4;

[0036] S2. Fix the die 7 whose middle part is depressed downward to form a groove, place the slab 6 on the top of the die 7, place the blank holder 2 on the upper end of the slab 6, and give the slab 6 a certain blank holder force , at the same time, the punch 5 is placed above the slab 6 corresponding to the groove;

[0037] S3, passing a high-frequency AC current of a certain size to the coil 3 to generate a rapidly changing...

Embodiment 2

[0041] When deep-drawing the box-shaped part, the shape of the blank holder 2 is selected as a rectangle, and there is a circular cavity inside, and the coil 3 is wound in the cavity, such as Figure 8-9 As shown, then according to the steps of embodiment 1, deep drawing can be carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com