A Circuit of Four Half-Bridge Sensors Connected in Series and Four Corners to Measure the Electronic Scale

A technology of sensors and electronic scales, applied in measuring devices, instruments, weighing, etc., can solve the problems of unable to measure the output of pressure sensors, the accuracy can only reach 1/200, and the production pass rate is not high, so as to improve the production pass rate, The effects of improved accuracy and improved four-corner eccentric load performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

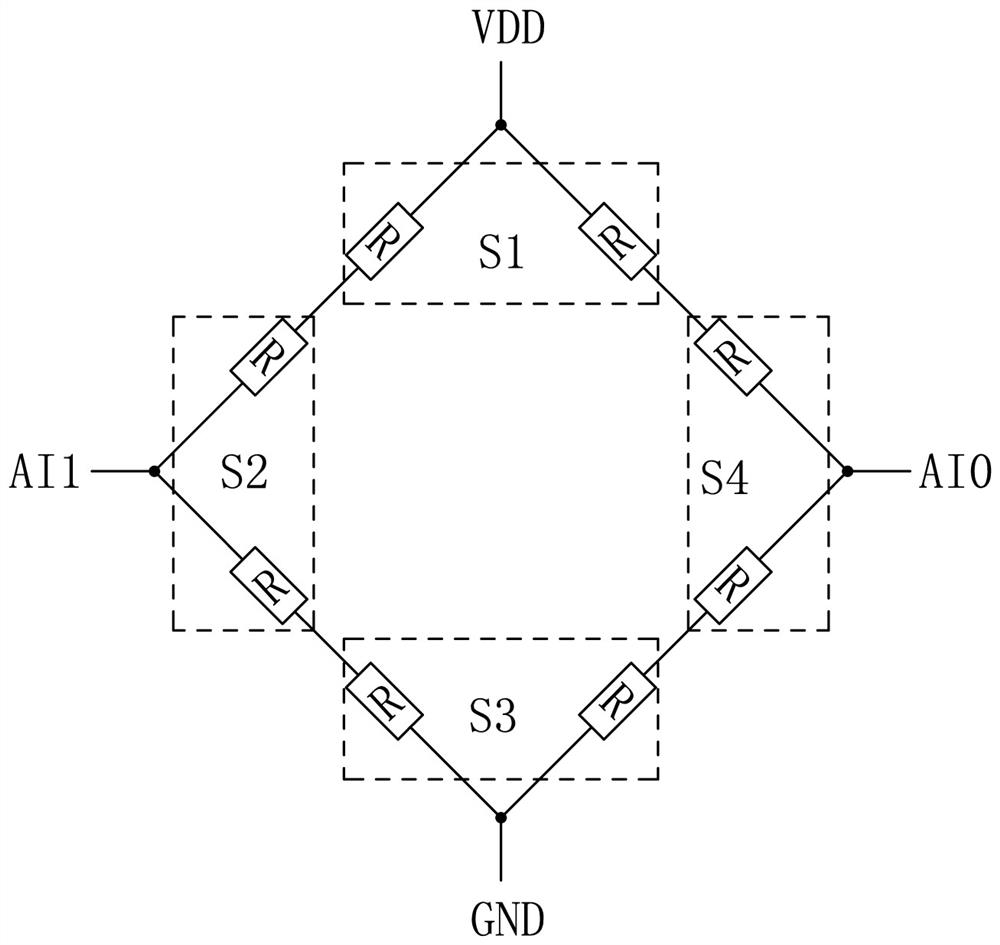

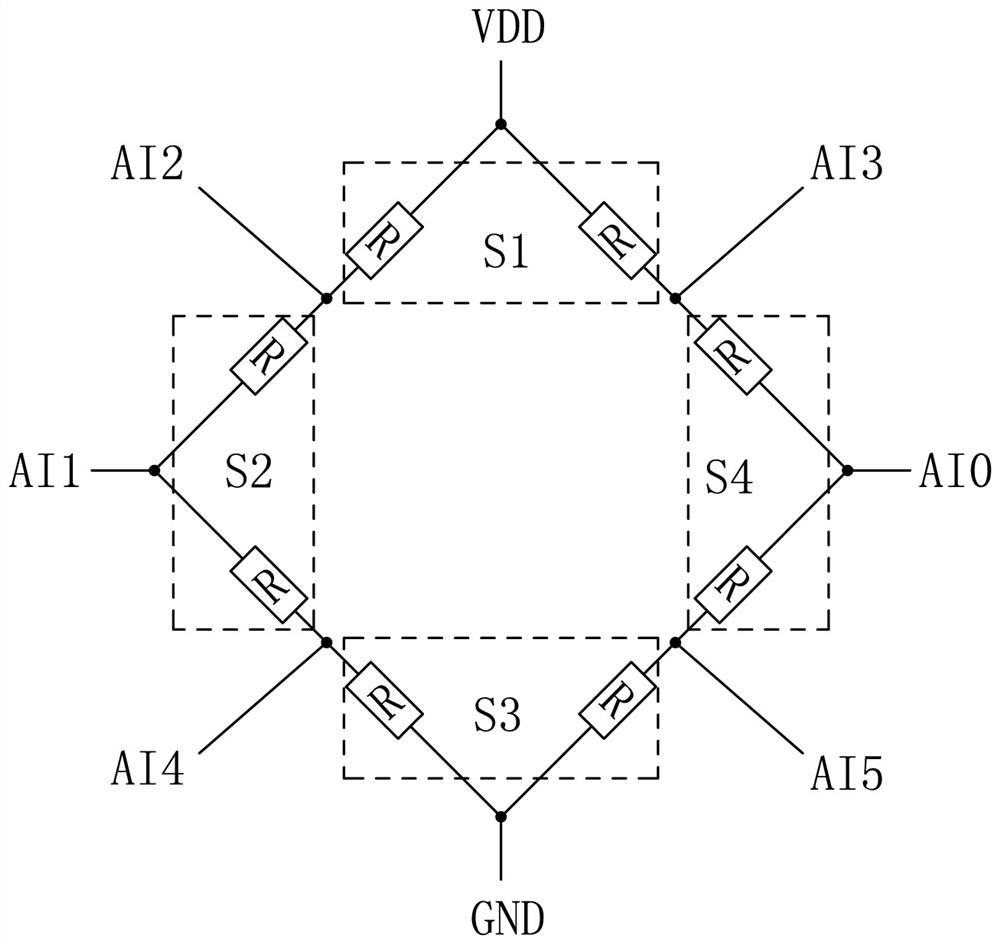

[0010] refer to figure 2 , a four-half-bridge sensor connected in series four-corner measuring electronic scale circuit, including four resistive pressure sensors S1, pressure sensor S2, pressure sensor S3 and pressure sensor S4, the pressure sensor S1, pressure sensor S2, pressure sensor S3 Both pressure sensor S4 and pressure sensor S4 include two resistors R connected in series. The pressure sensor S1, pressure sensor S4, pressure sensor S3 and pressure sensor S2 are sequentially connected in series to form a bridge with power contacts and six signal measuring points. The power contacts Including the positive power supply VDD connected to the junction of the two resistors R in the pressure sensor S1 and the negative power supply GND connected to the junction of the two resistors R in the pressure sensor S3, the six signal measuring points are respectively : the measurement terminal AI0 connected to the node of two resistors R in the pressure sensor S4, the measurement term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com