Hillside orchard trencher

A ditching machine and orchard technology, which is applied in the direction of excavation/covering ditch holes, planting methods, applications, etc., can solve the problems of gravel damage to the ditching machine, irregular ditching, and insufficient ditching depth, etc., to ensure the ditching ditch quality, neat ditch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

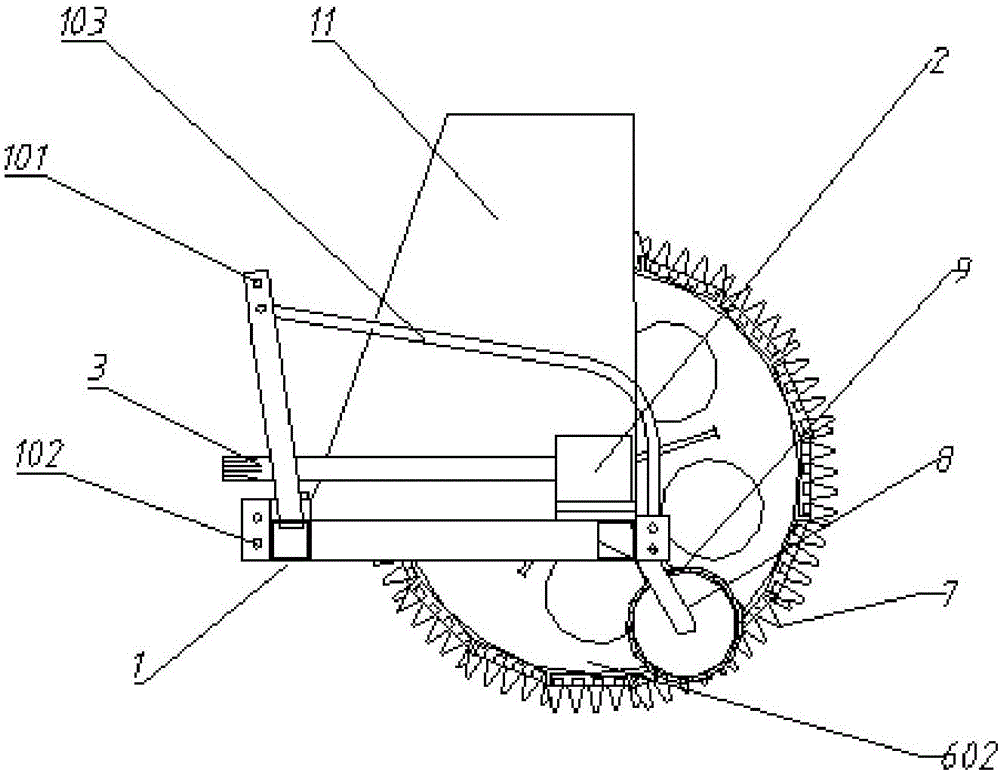

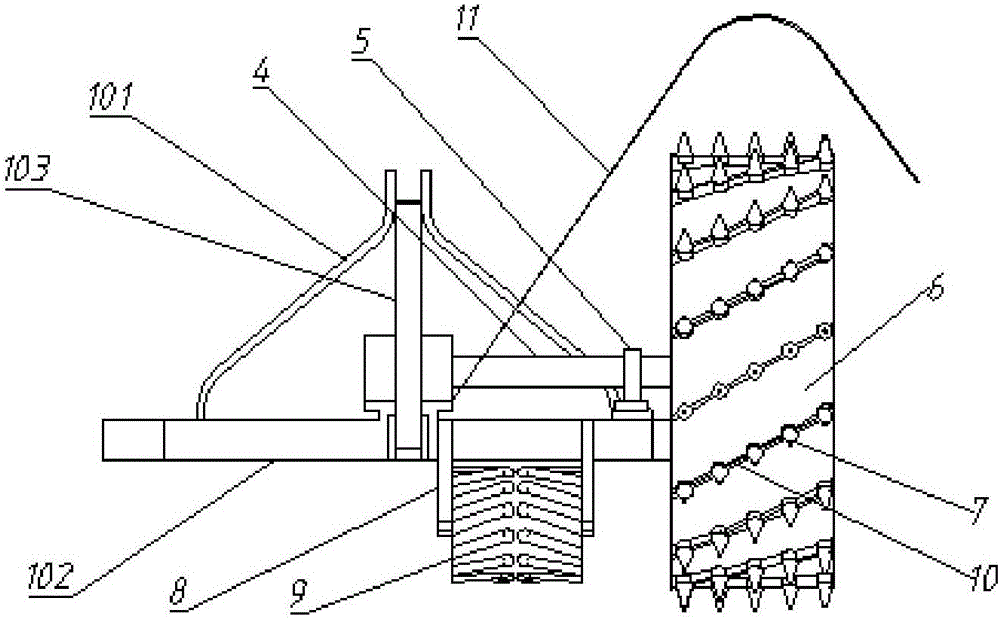

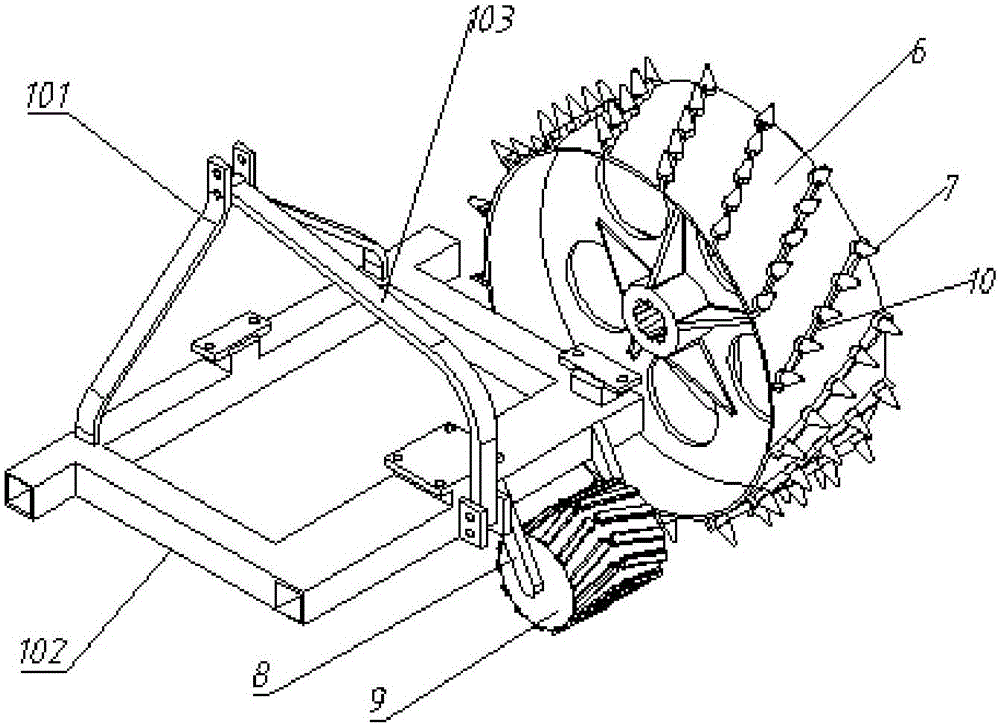

[0021] Such as Figure 1-4 As shown, one specific embodiment of a mountain orchard ditching machine includes a frame 1 movably connected with a locomotive, and the frame 1 includes an upper suspension seat 101 , a lower suspension seat 102 and an upper suspension tie rod 103 . Both the upper suspension seat 101 and the lower suspension seat 102 are bolted to the locomotive, and the lower end of the upper suspension seat 101 is welded to the lower suspension seat 102 . The lower suspension seat 102 extends symmetrically to both sides, and the concrete underground suspension seat is welded by rectangular steel pipes (refer to image 3 ). The two ends of the upper suspension pull rod 103 are respectively connected by bolts to the upper end of the upper suspension seat 101 and the lower suspension seat 102 away from the side of the connection end, so that the frame is more stable. The locomotive drags forward.

[0022] A gearbox 2 is installed in the middle of the frame 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com