Furrowing and ridging device with adjustable furrow depth

A deep furrow technology, applied in planting methods, digging/covering ditches, shovels, etc., can solve the problems of not being able to complete ridging and rotary tillage at the same time, and achieve improved work efficiency and economic benefits, flexibility and The effect of improving adaptability and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

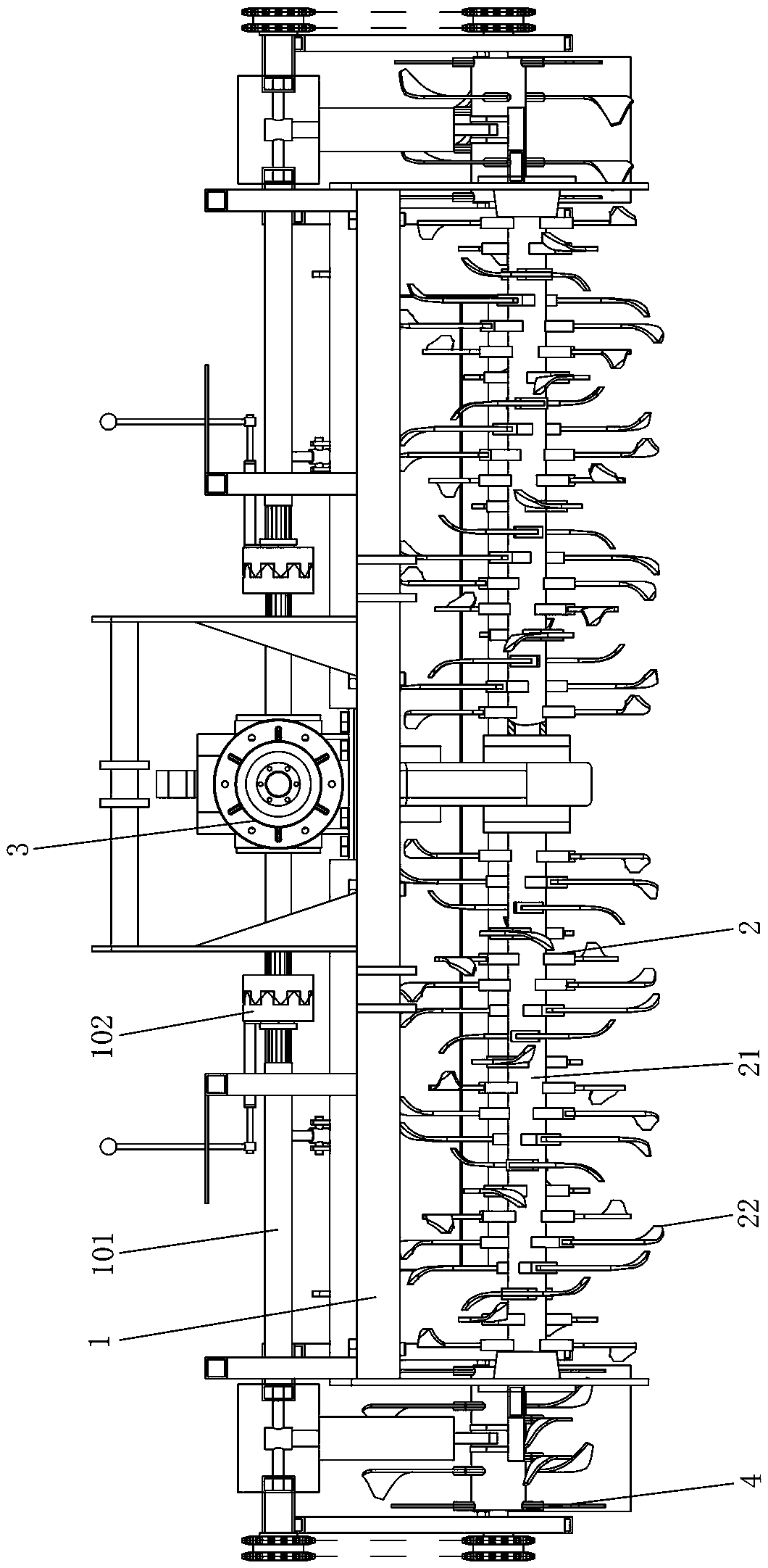

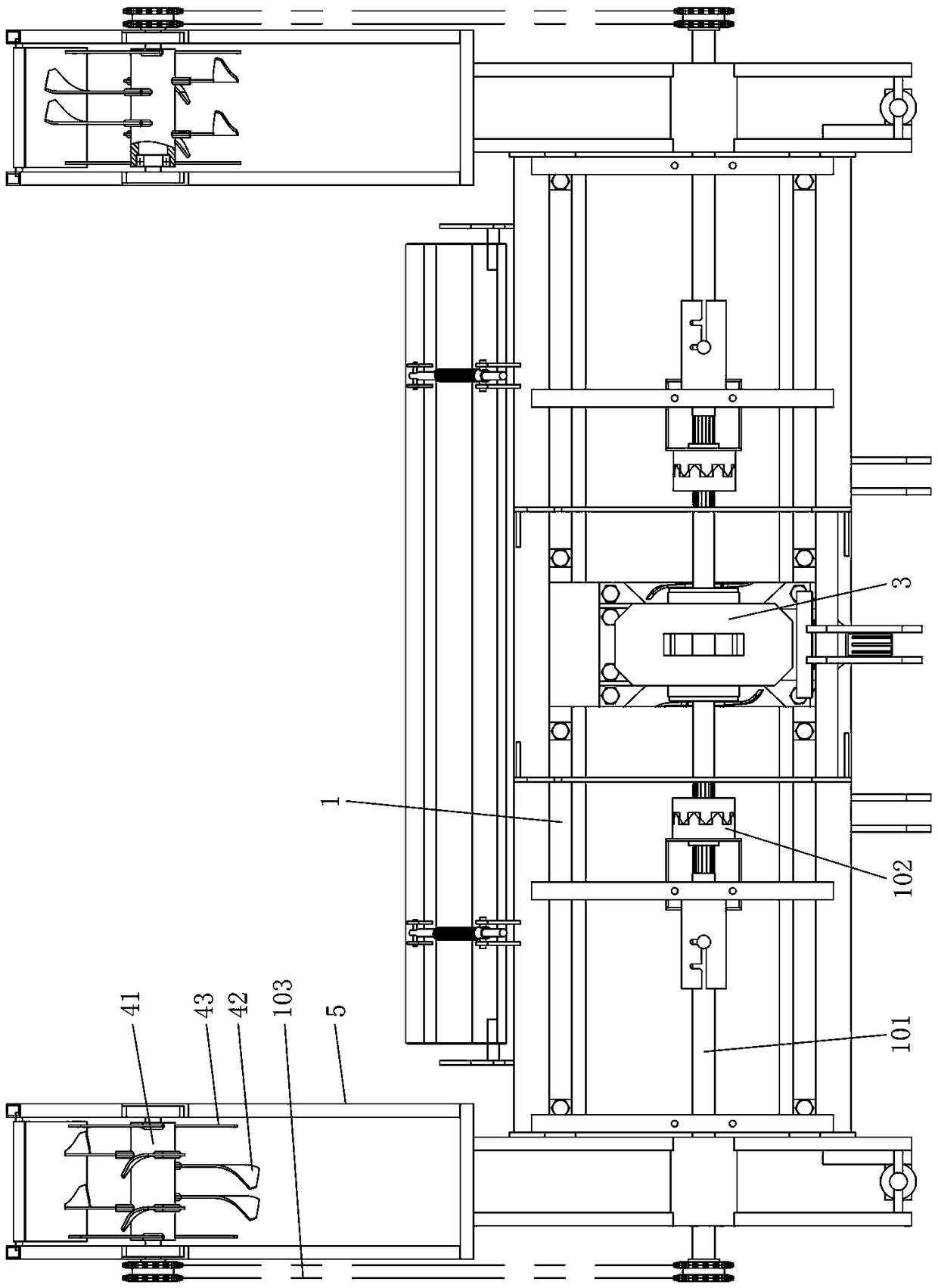

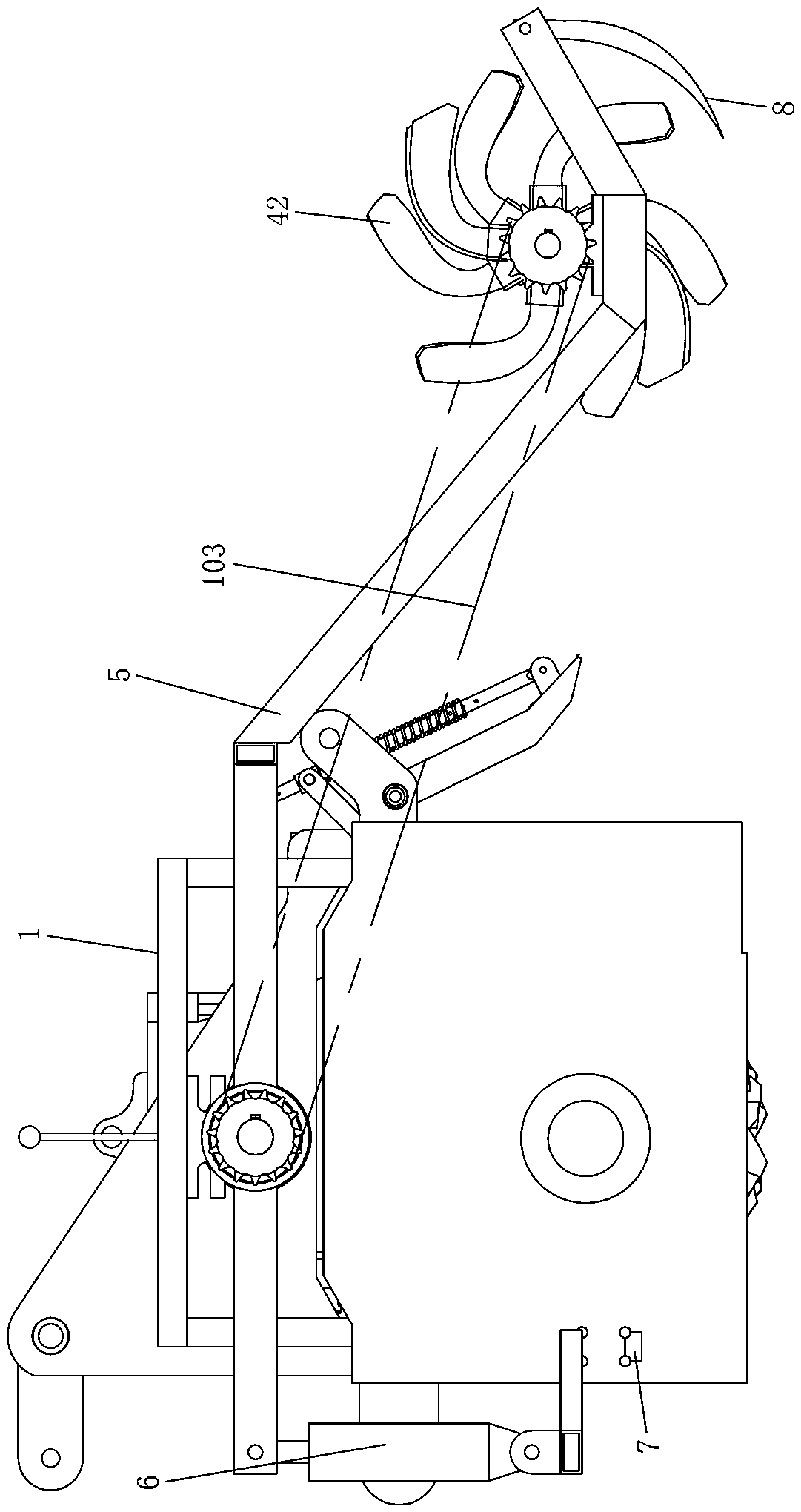

[0023] Such as Figure 1 to Figure 4 As shown, the box-forming ridging device with adjustable furrow depth of the present embodiment includes a frame 1 on which a rotary tillage assembly 2 and a gearbox 3 are installed, and the gearbox 3 is connected with the rotary tillage assembly 2 for Drive the rotary tillage assembly 2 to work, and the rear of both sides of the rotary tillage assembly 2 are provided with ditching and ridge assembly 4 connected to the gearbox 3, and each ditch and ridge assembly 4 is installed in a height-adjustable manner through the groove depth adjustment mechanism on rack 1. The box-forming and ridge-forming device with adjustable furrow depth is installed on tractors and other traction implements to work. First, the front-mounted rotary tillage assembly 2 performs rotary tillage on the soil, and then the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com