a tray structure

A tray and tray seat technology, applied in the direction of rigid containers, containers, packaging, etc., can solve the problems of poor adaptability of automatic moving mechanism, affect the handling efficiency and quality of electronic components, and easily damage electronic components, so as to ensure the handling efficiency and Quality, Less Injury, Adaptable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

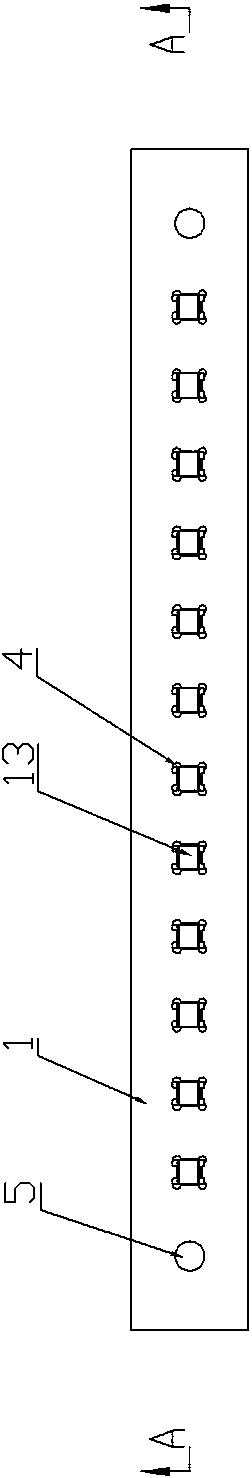

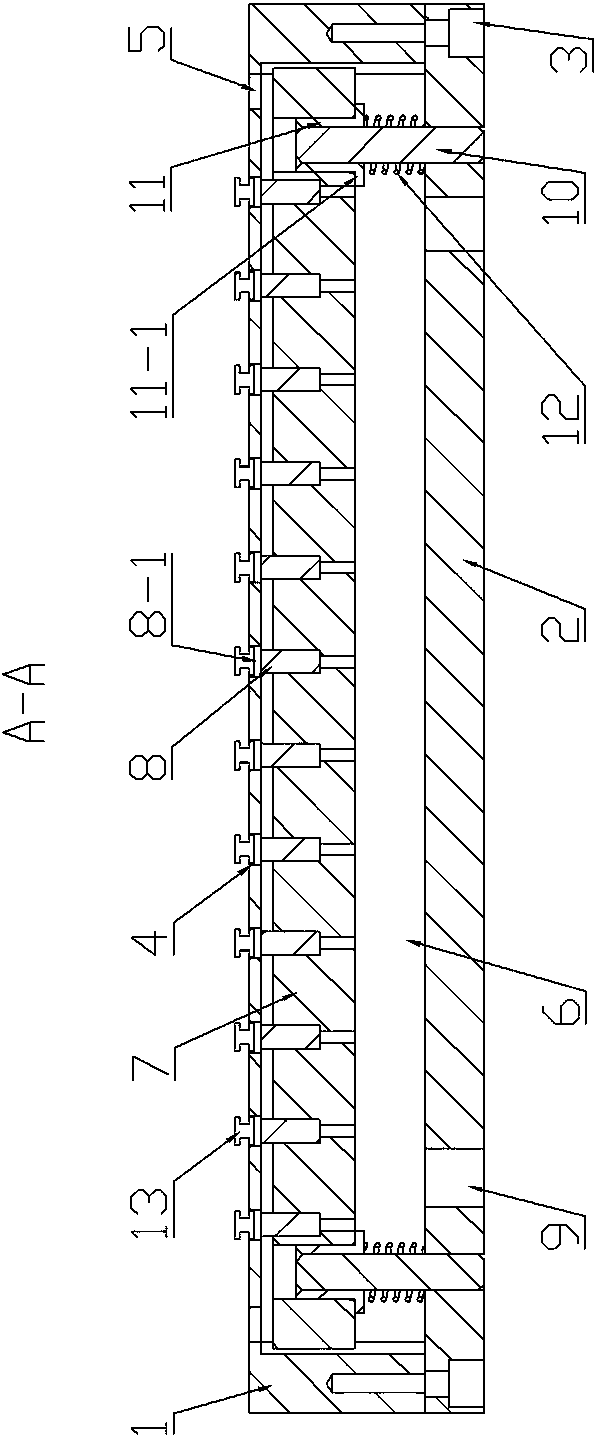

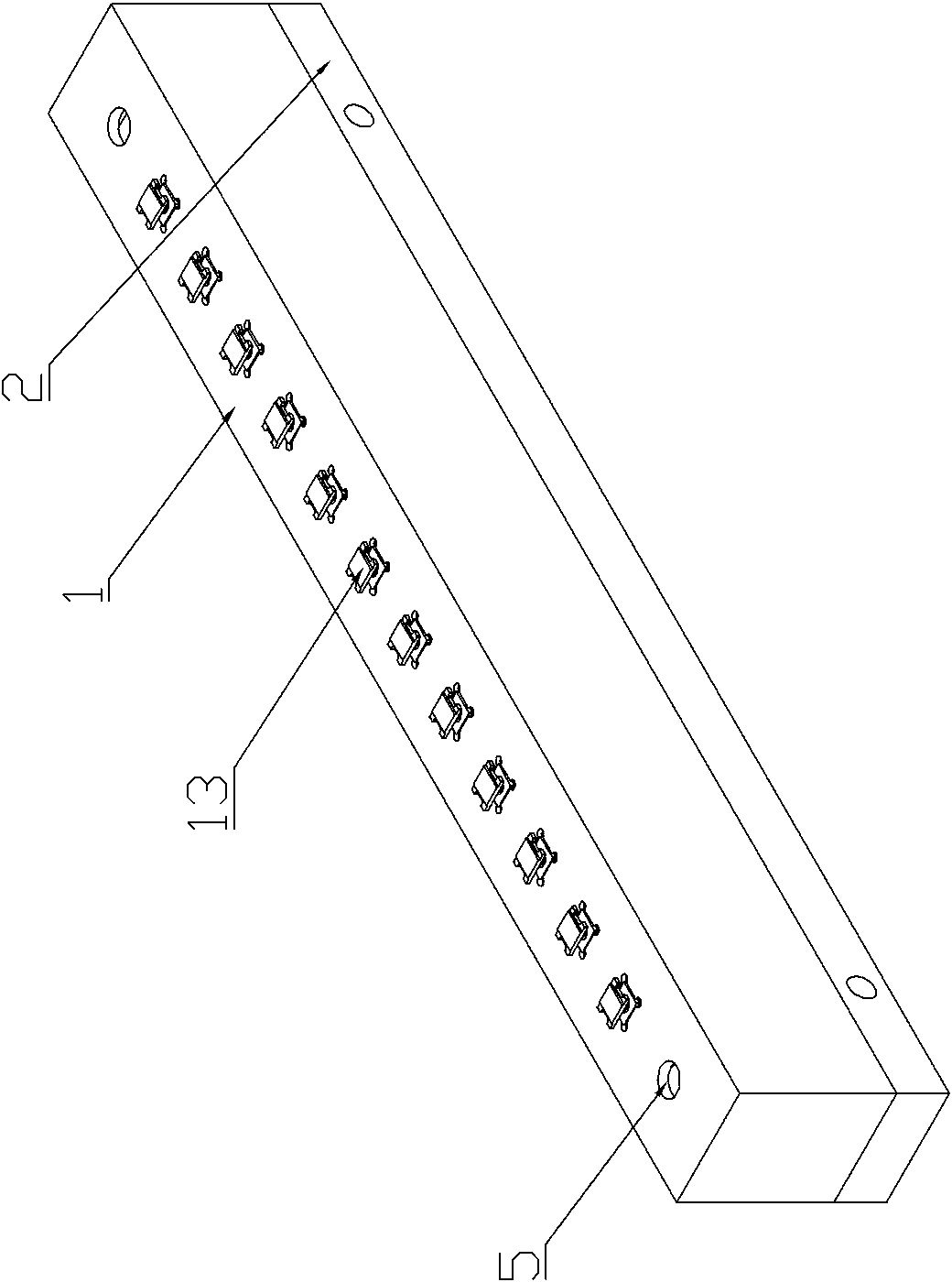

[0013] Such as Figure 1-Figure 3 As shown, a pallet structure includes a pallet base 1 and a bottom plate 2. The pallet base 1 is installed on the bottom plate 2 through screws 3. There are 12 workpiece placement slots 4 uniformly opened in the middle of the top of the pallet base 1, and the two sides of the top are symmetrical. The limited hole 5 is set, the tray seat 1 and the bottom plate 2 form a cavity 6, and a movable seat plate 7 is arranged in the cavity 6, and 12 tray columns 8 are evenly distributed on the movable seat plate 7, and the 12 tray columns 8 are respectively Embedded in the movable seat plate 7, the 12 tray columns 8 are compatible with the 12 workpiece placement slots 4 and can slide in the workpiece placement slots 4. The bottom of the tray seat 1 is symmetrically provided with positioning holes 9, and the movable seat plate 7 The two sides are respectively connected to the bottom plate 2 by pins 10, the bushing 11 is sleeved on the pins 10, the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com