A mechanical choke fishing tool and its operating method

A salvage tool and choke technology, applied in the field of mechanical choke salvage tools, can solve the problems of high cost and low salvage success rate, and achieve simple structure, easy inspection of tool conditions, low-cost salvage technology and economy. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

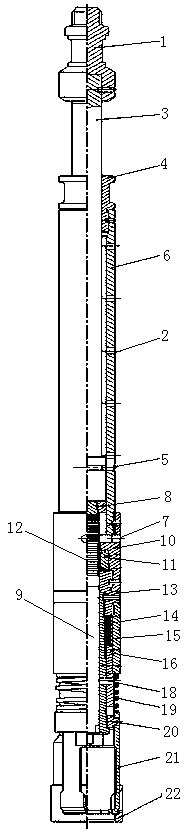

[0036] In order to overcome the problems of high cost and low success rate of salvage in the prior art, this embodiment provides a method such as figure 1 As shown in the mechanical throttle fishing tool, the upper end of the fishing mechanism is sequentially connected with a control rod mechanism and a shock rod mechanism, and the shock rod mechanism includes a shock rod 3 and an outer cylinder 6, and the shock rod 3 The upper end is connected to the upper joint 1, the outer side of the shock rod 3 is covered with a nut 4, the bottom end of the shock rod 3 is provided with a boss outside, the shock rod 3 is placed in the outer cylinder 6, and the nut 4 is connected to the inner side of the upper end of the outer cylinder 6, The lower end of the inner cylinder 6 is inserted with a shear pin 5, and the shear pin 5 is located below the shock rod 3. The control rod mechanism includes a control rod 9, a fixed sleeve 10 and a connecting seat 13. The upper end of the fixed sleeve 10 ...

Embodiment 2

[0044] On the basis of embodiment 1, this embodiment provides a kind of figure 1 In the fishing tool with mechanical restrictor shown, in order to prevent the tool from holding pressure during operation, the side wall of the outer cylinder 6 is provided with a vent hole 2 .

[0045] Further, the fixing sleeve 10 is provided with an observation hole 7 , and when the shear pin 5 is not cut, the observation hole 7 is aligned with the threaded lower end of the control rod 9 . The downward movement position of the control rod can be observed from the observation hole 7, which is convenient for checking the condition of the tool. At the same time, the observation hole 7 also has the effect of ventilation, so as to ensure that the fishing process is carried out normally.

Embodiment 3

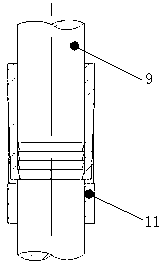

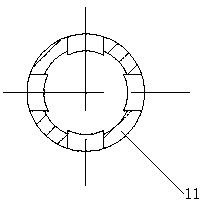

[0047] On the basis of embodiment 2, this embodiment provides a kind of figure 1 In the mechanical throttle fishing tool shown, a spacer sleeve 11 is embedded between the limit step of the fixed sleeve 10 and the connecting seat 13, the spacer sleeve 11 is internally connected to the circlip 12, and the control rod 9 is placed In the jump ring 12, and the top of the control rod 9 is provided with threads;

[0048] Alternatively, telescopic steps are provided on the inner wall of the spacer sleeve 11 , and an inverted tapered thread is provided above the control rod 9 .

[0049] When the restrictor is unsealed, the nut 8 and the control rod 9 are moved downward by the impact of the shock rod 3, and the thread on the control rod 9 is stuck in the retaining spring 12. When the shock rod 3 goes up, the control rod 9 cannot go up. , or the inverted tapered thread on the top of the control rod 9 is stuck on the telescopic step on the inner wall of the spacer sleeve 11. When the sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com