Underground throttle fishing tool and operation method thereof

A technology for fishing tools and chokes, which is applied in the field of downhole choke fishing tools and fishing, can solve the problems of low success rate and high cost, and achieve the effects of high success rate, simple structure, low-cost technology and economical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

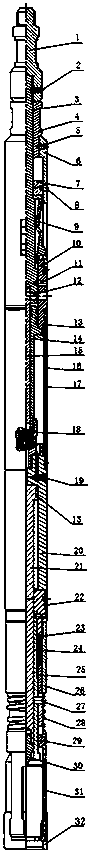

[0027] This embodiment provides a method such as figure 1 The downhole choke fishing tool shown includes a pressure control mechanism and a fishing mechanism connected up and down.

[0028] Connect the pressure control mechanism and the fishing mechanism to form a fishing tool. After the fishing tool is lowered to the top of the throttle through the well test wire, the fishing tool is quickly lowered, and then the fishing tool is slowly raised. When the lifting force is greater than the hanging weight, the fishing tool After grabbing the fishing neck of the throttle, unblock the throttle, and lift up the fishing tool to lift the throttle.

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 As shown, the pressure control mechanism includes an upper joint 1, the inner wall of the lower end of the upper joint 1 is connected to the shock rod 3 through a pin 2, the lower end of the upper joint 1 is connected to a nut 4, and the nut 4 is connected by a flat-end fastening screw 5. The guide tube 6 is provided with a shear sleeve 7 between the inner wall of the guide tube 6 and the outer wall of the shock rod 3. The shear sleeve 7 and the guide tube 6 are connected by a shear pin 8 and the lower end of the guide tube 6 is connected to the outer cylinder 10. , The outer cylinder 10 and the shock rod 3 are connected by a shear pin 11, the lower inner wall of the outer cylinder 10 is connected to a small oil cylinder 14. The top of the small oil cylinder 14 and the bottom end of the shock rod 3 are left with a gap, and the inner wall below the shock rod 3 A piston rod 15 is connected. The piston rod 15, the shock rod 3 and ...

Embodiment 3

[0035] On the basis of embodiment 1, the fishing mechanism includes a connecting seat 22, a spring 23, a mandrel 24, a spacer ring 25, a support tube 26, a safety shear pin 27, a rectangular spring 28, a connecting block 29, a claw 31, Locking sleeve 32;

[0036] The connecting seat 22 is connected to the lower end of the large oil cylinder 29, the support tube 26 and the mandrel 24 are respectively connected to the outside and the inside of the lower end of the connecting seat 22, the mandrel 24 is sleeved on the outside of the lower part of the ejector 30, and the spring 23 and the spacer ring 25 are arranged up and down in the core. Between the shaft 24 and the support tube 26, the spacer ring 25 and the core shaft 24 are fixed by the safety shear pin 27, the spring 23 is compressed and placed between the connecting seat 22 and the spacer ring 25, and the spacer ring 25 is sheathed with a rectangular spring 28, And the rectangular spring 28 is located under the support tube 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com