Patents

Literature

76results about How to "Avoid affecting follow-up work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

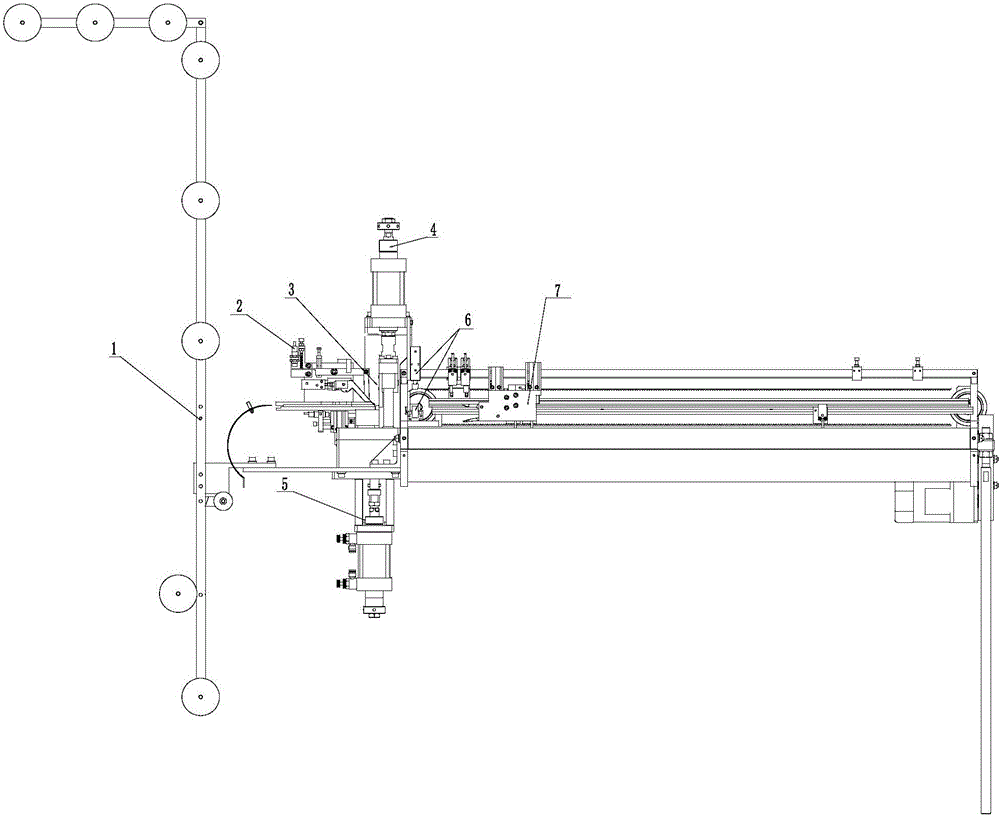

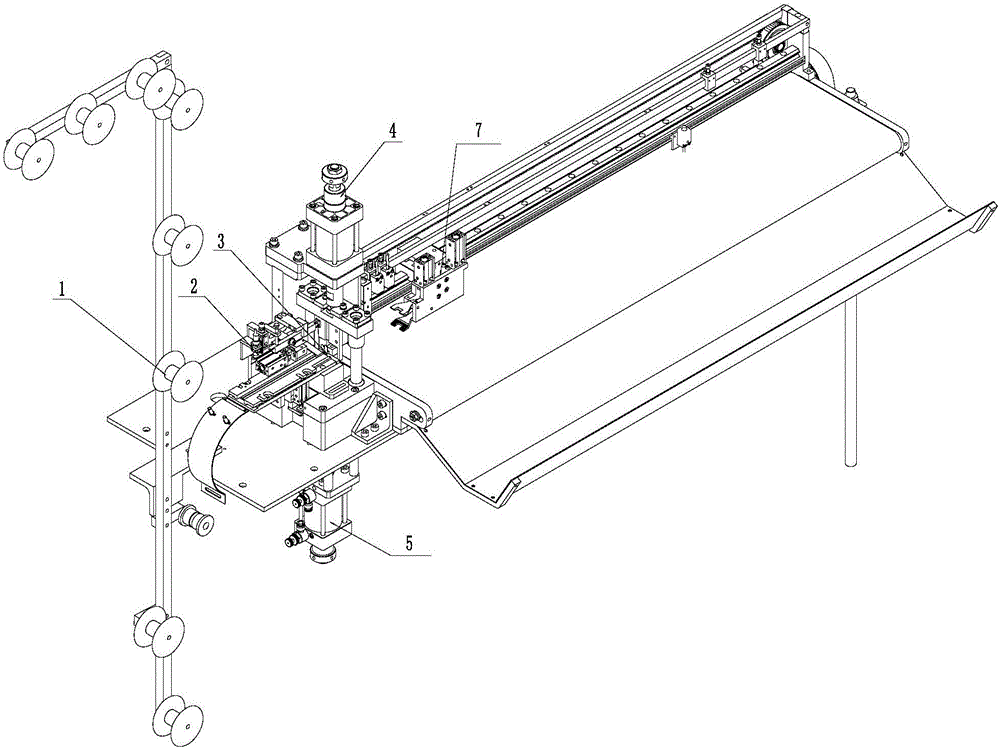

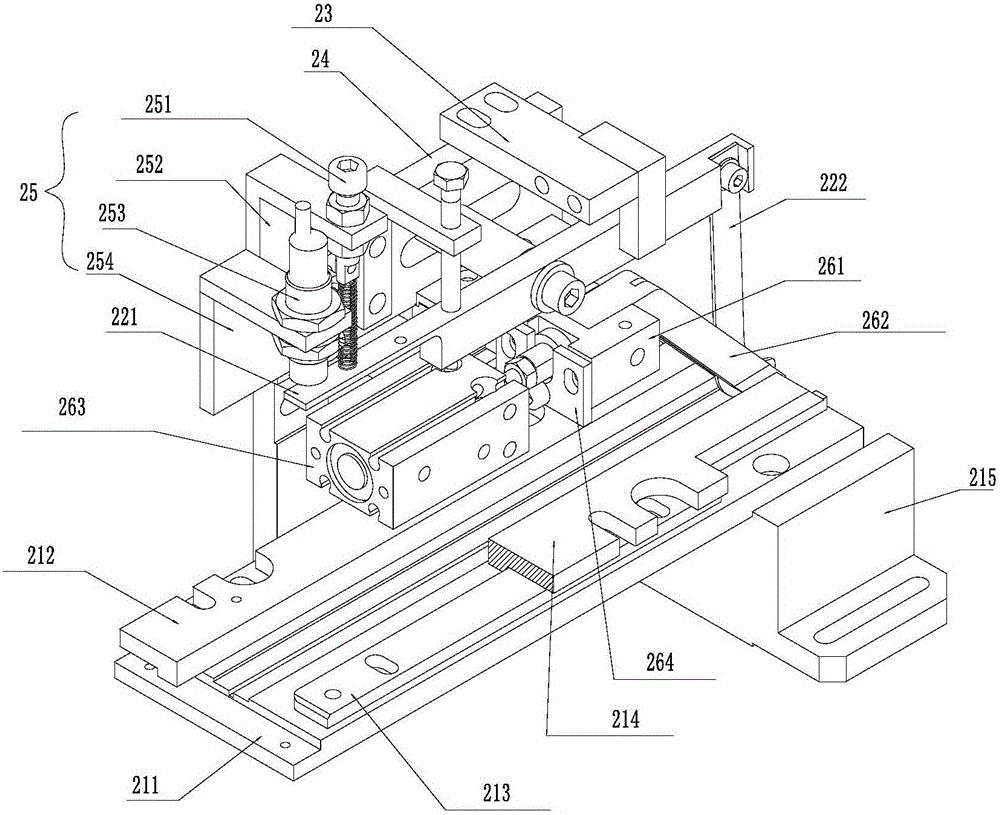

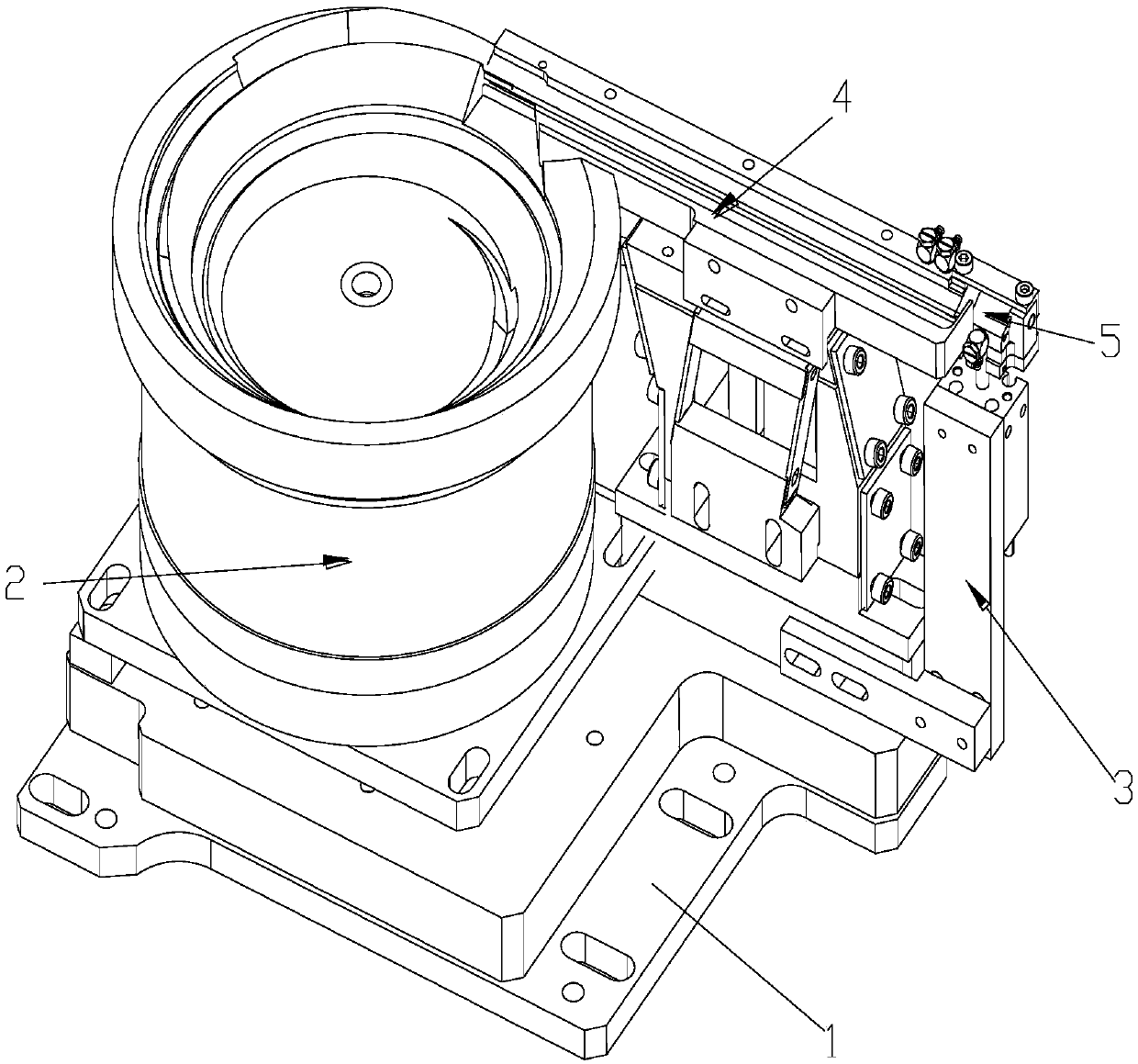

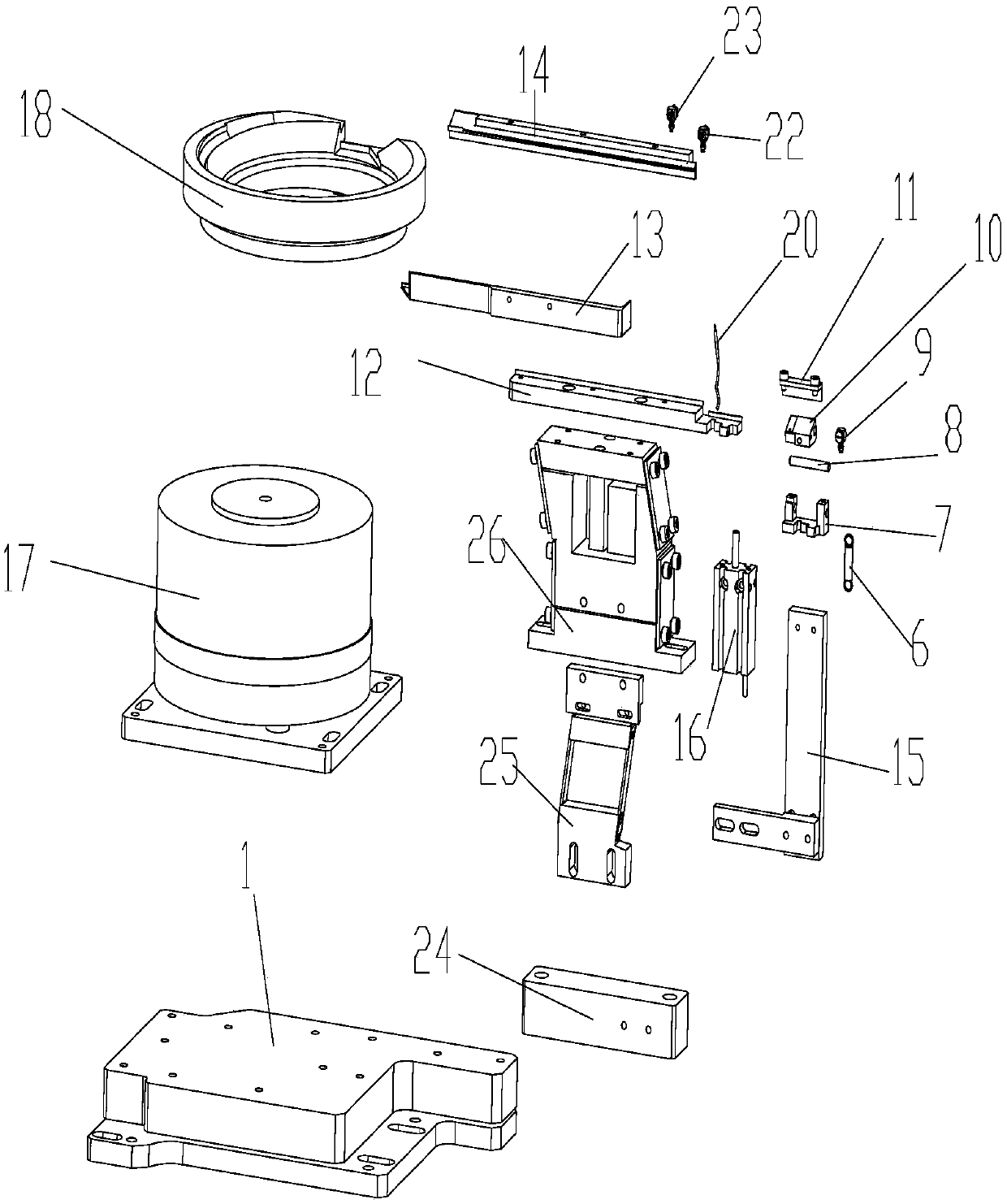

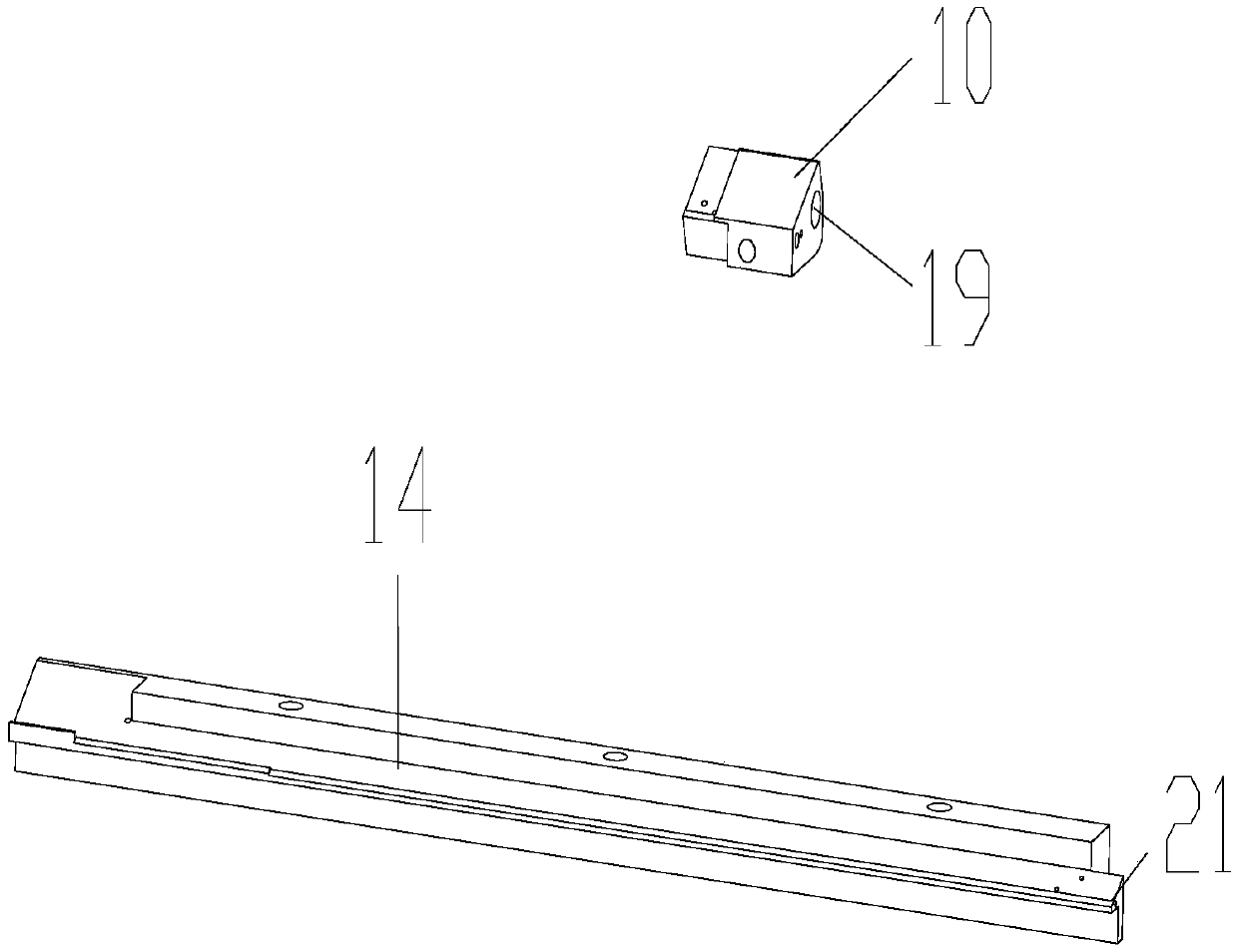

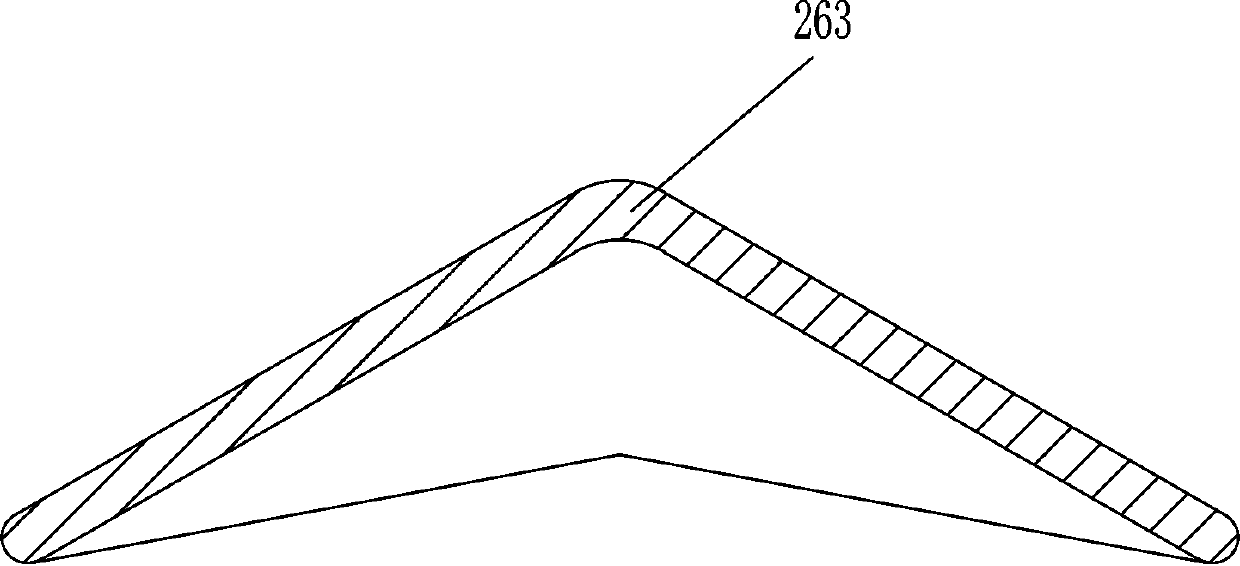

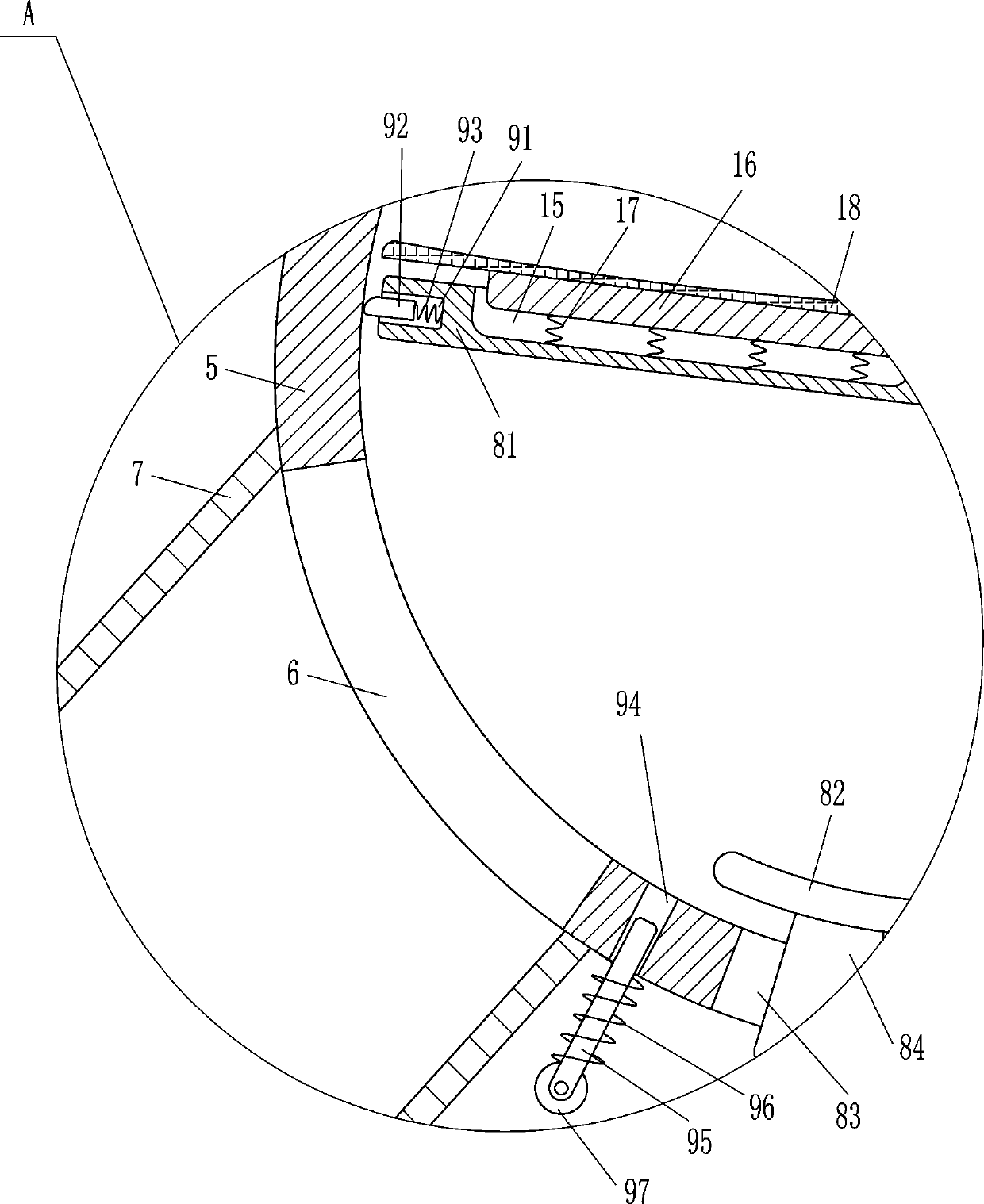

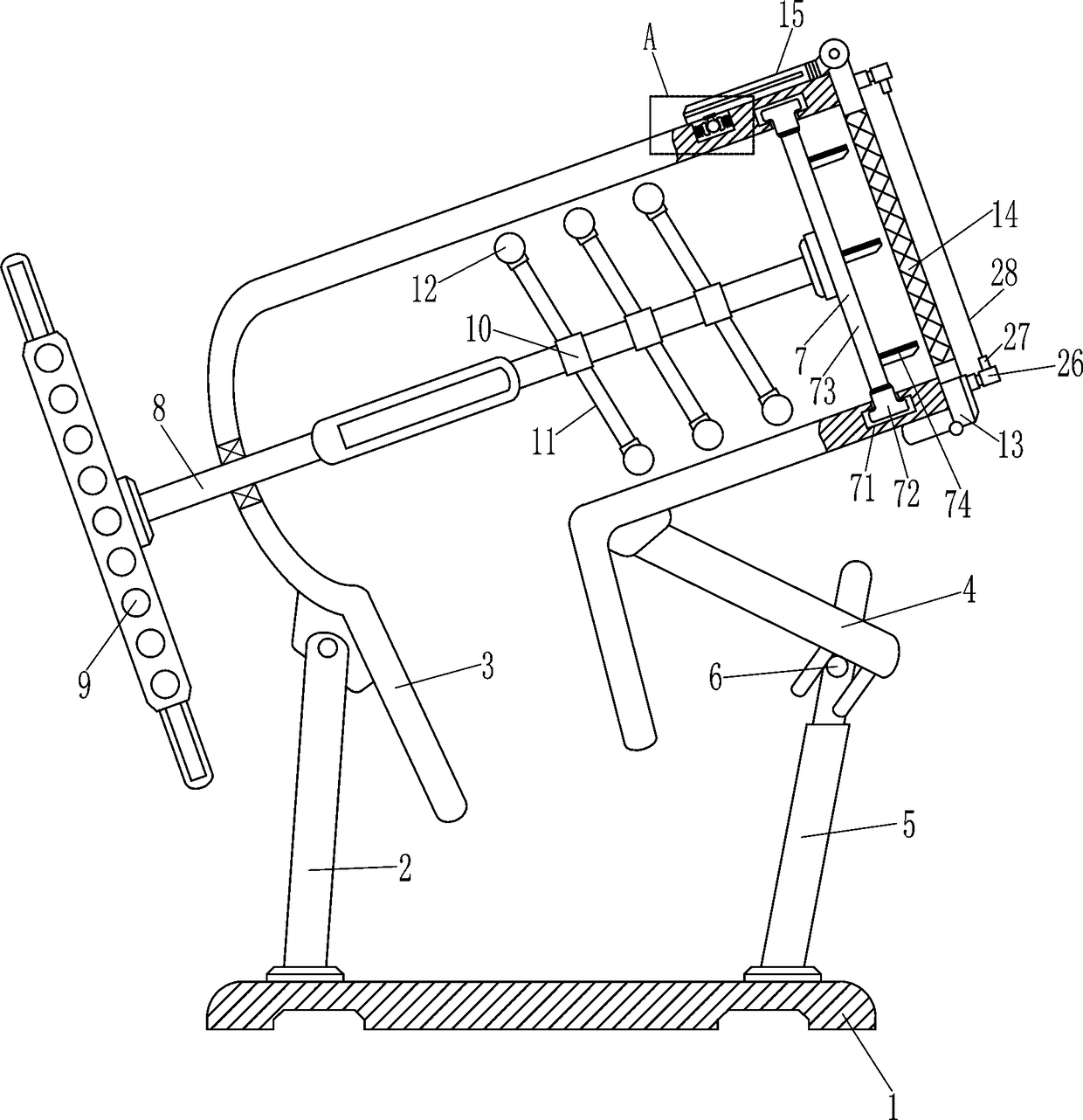

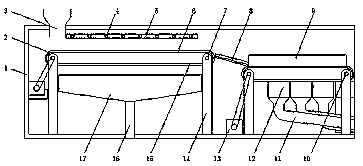

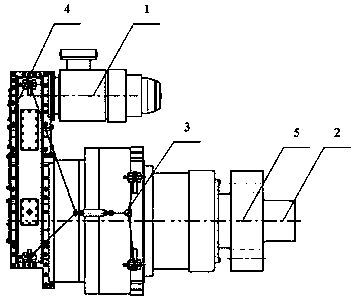

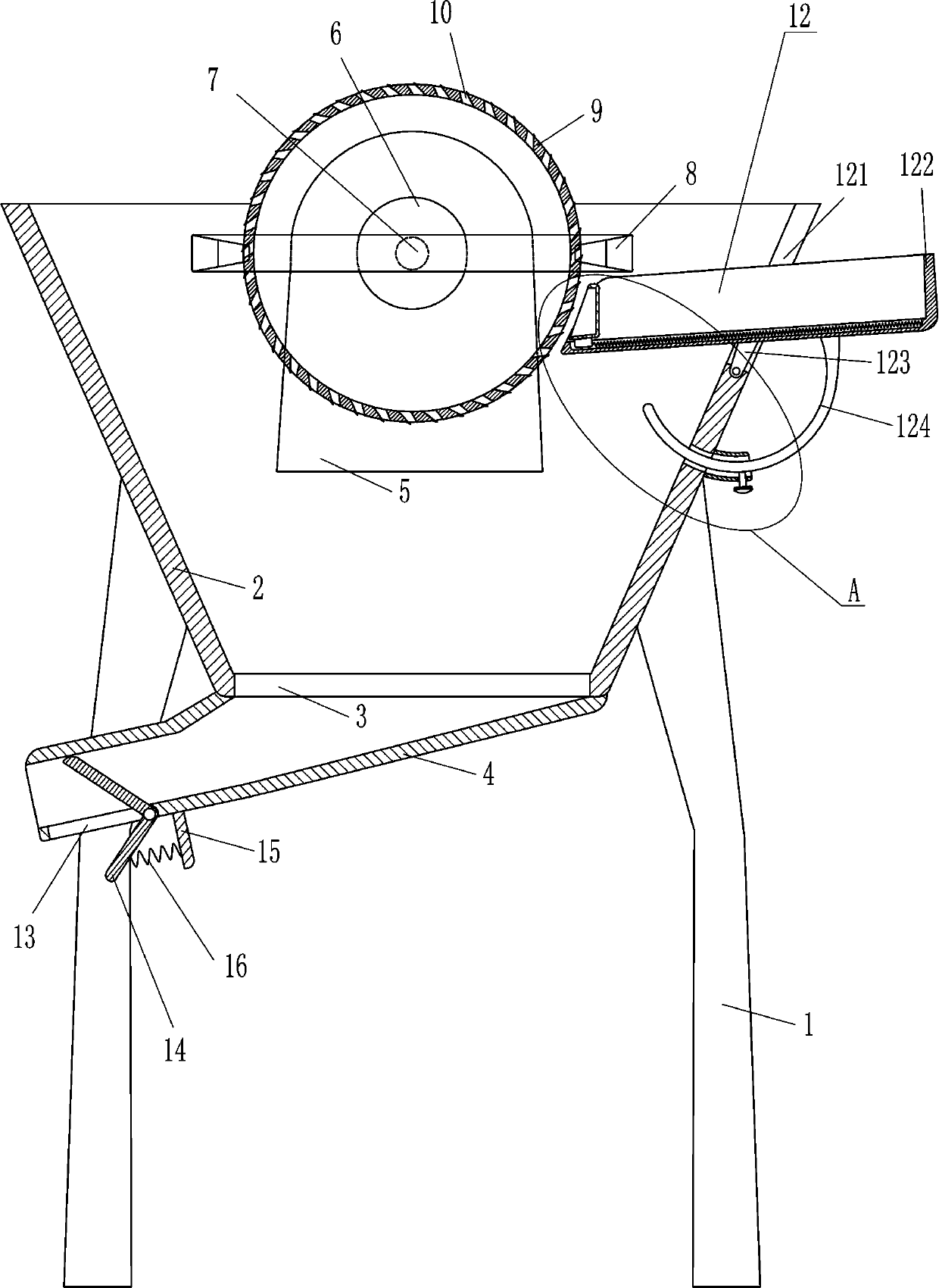

Full-automatic pulling tape opening cut-off machine

ActiveCN106037169AExtend your lifeGuaranteed disconnectionSlide fastenersMechanical engineeringEngineering

The invention provides a full-automatic pulling tape opening cut-off machine, which is capable of simultaneously completing two jobs, namely cutting off a zipper cloth tape and moving a pull head to the top end of a zipper. The cut-off machine comprises a tape feeding part, a mold base part, a lower knife movable part and a pulling tape hand clip part, and further comprises a pressing chain passing part, a hooked needle part and tape pull head devices. The cut-off machine is capable of simultaneously completing two jobs, namely cutting off the zipper cloth tape and moving the pull head to the top end of the zipper; and the cut-off machine is high in production efficiency.

Owner:广州市振宇拉链机械有限公司

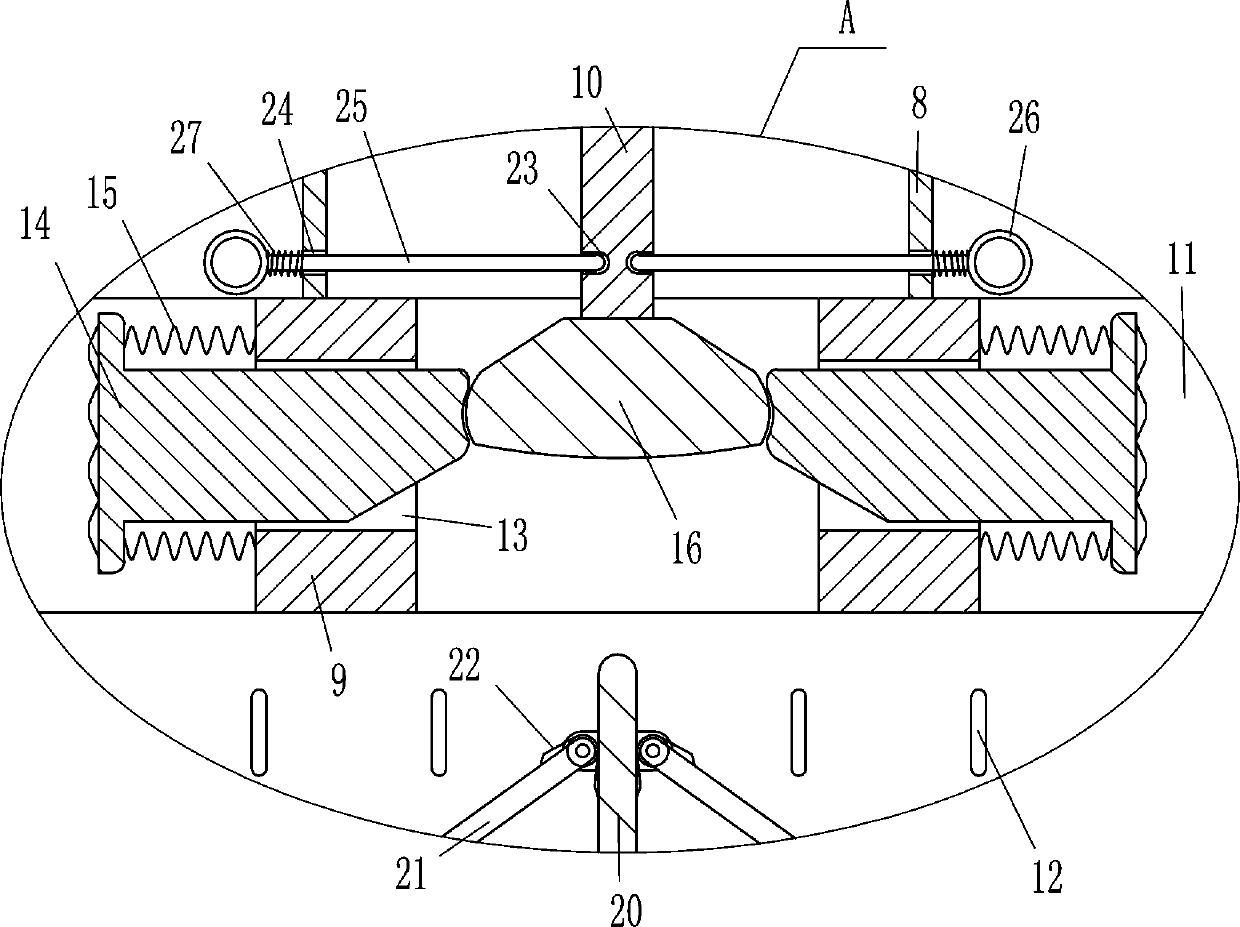

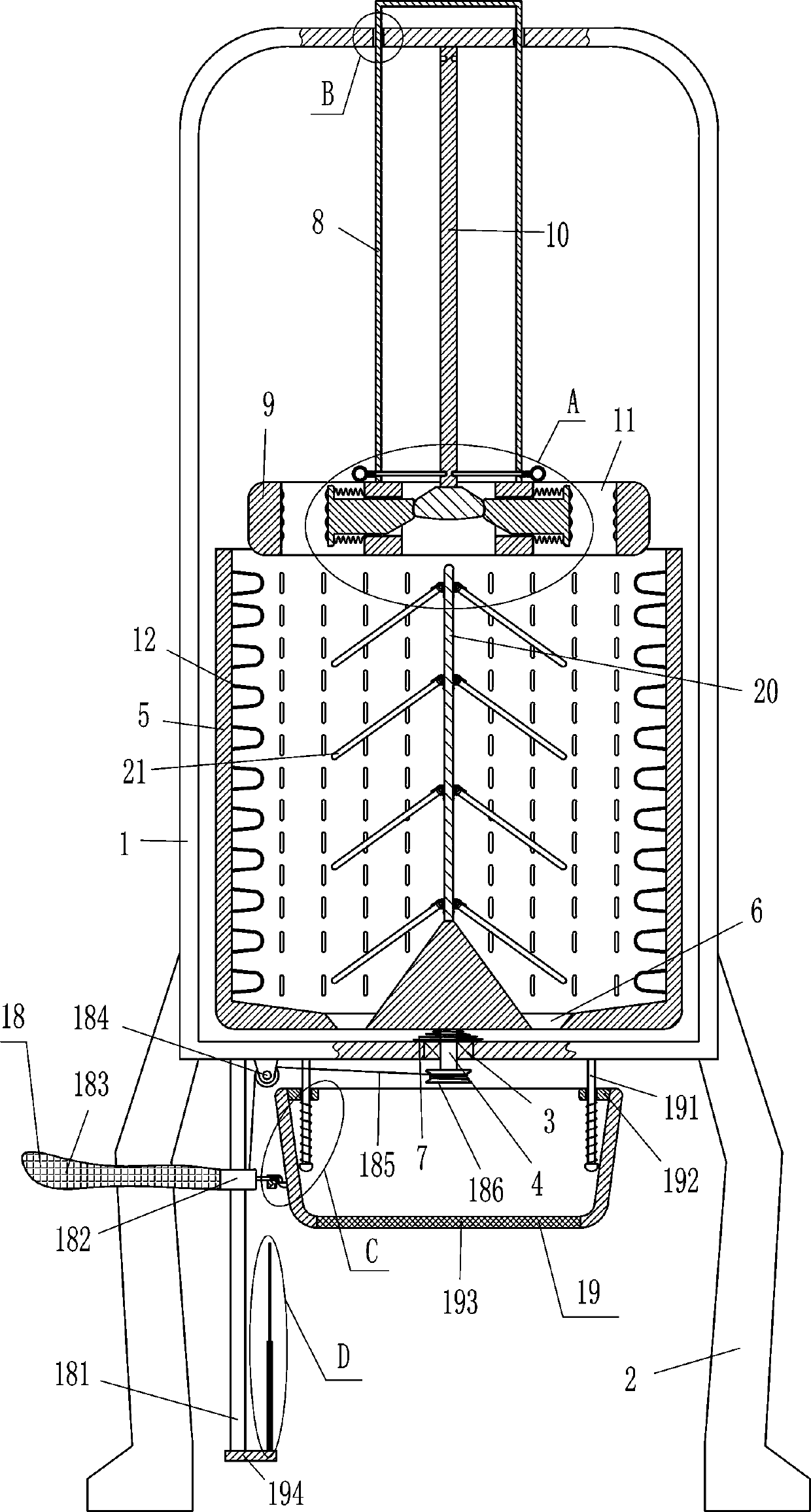

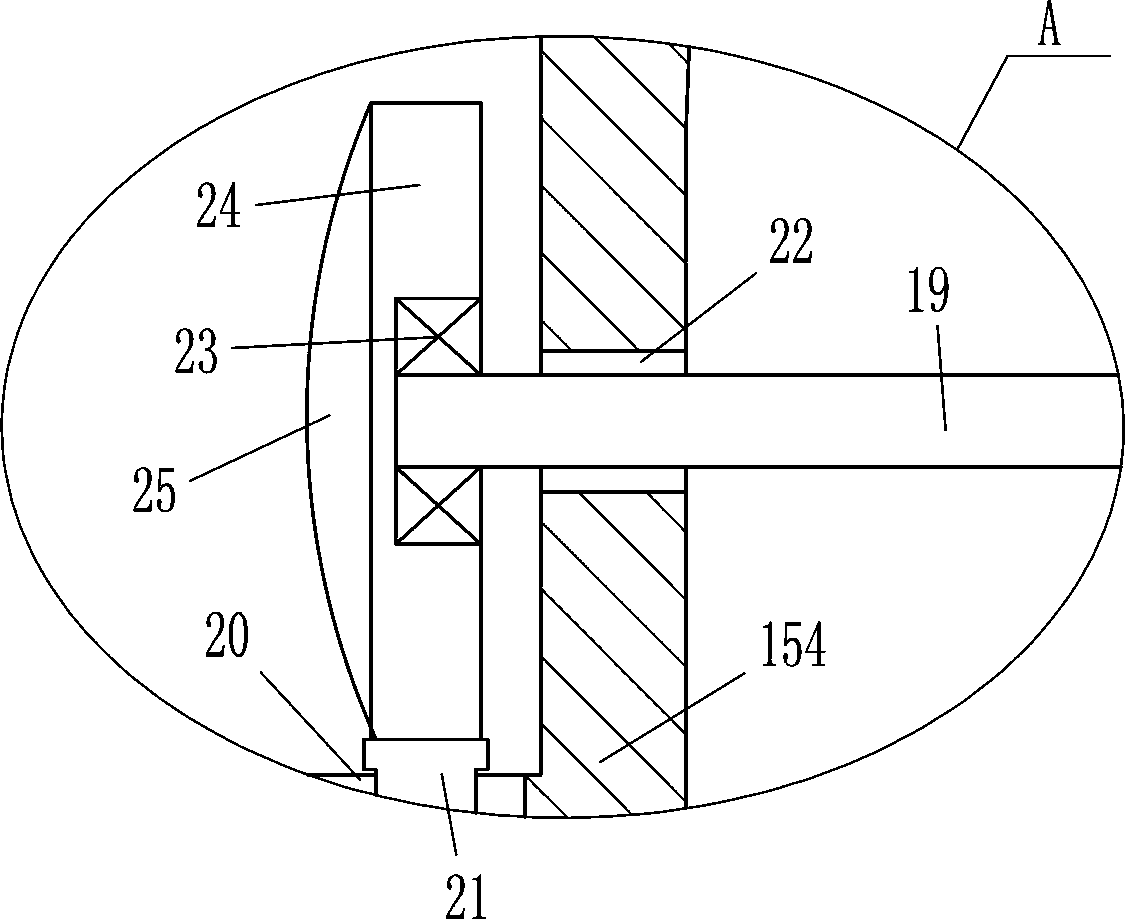

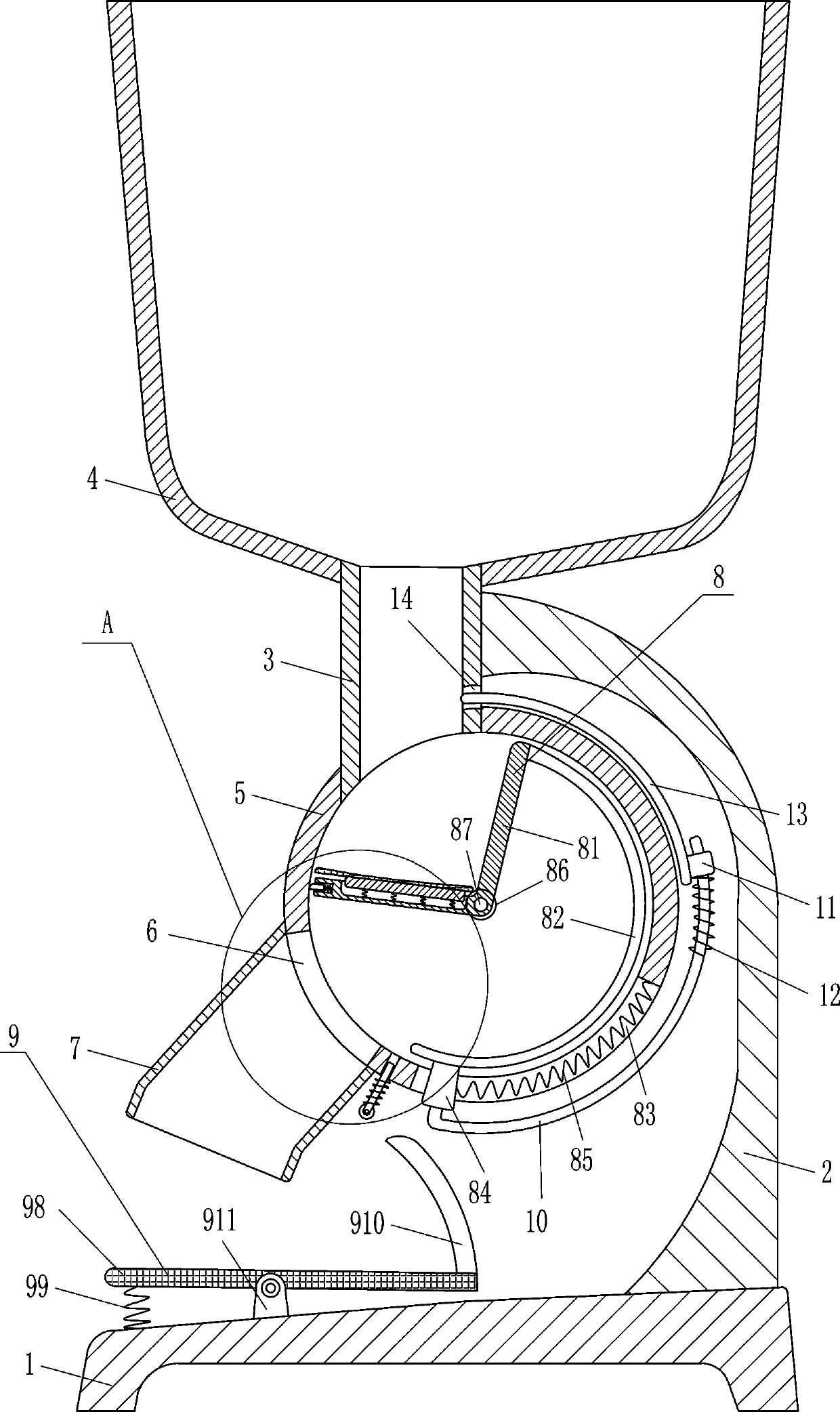

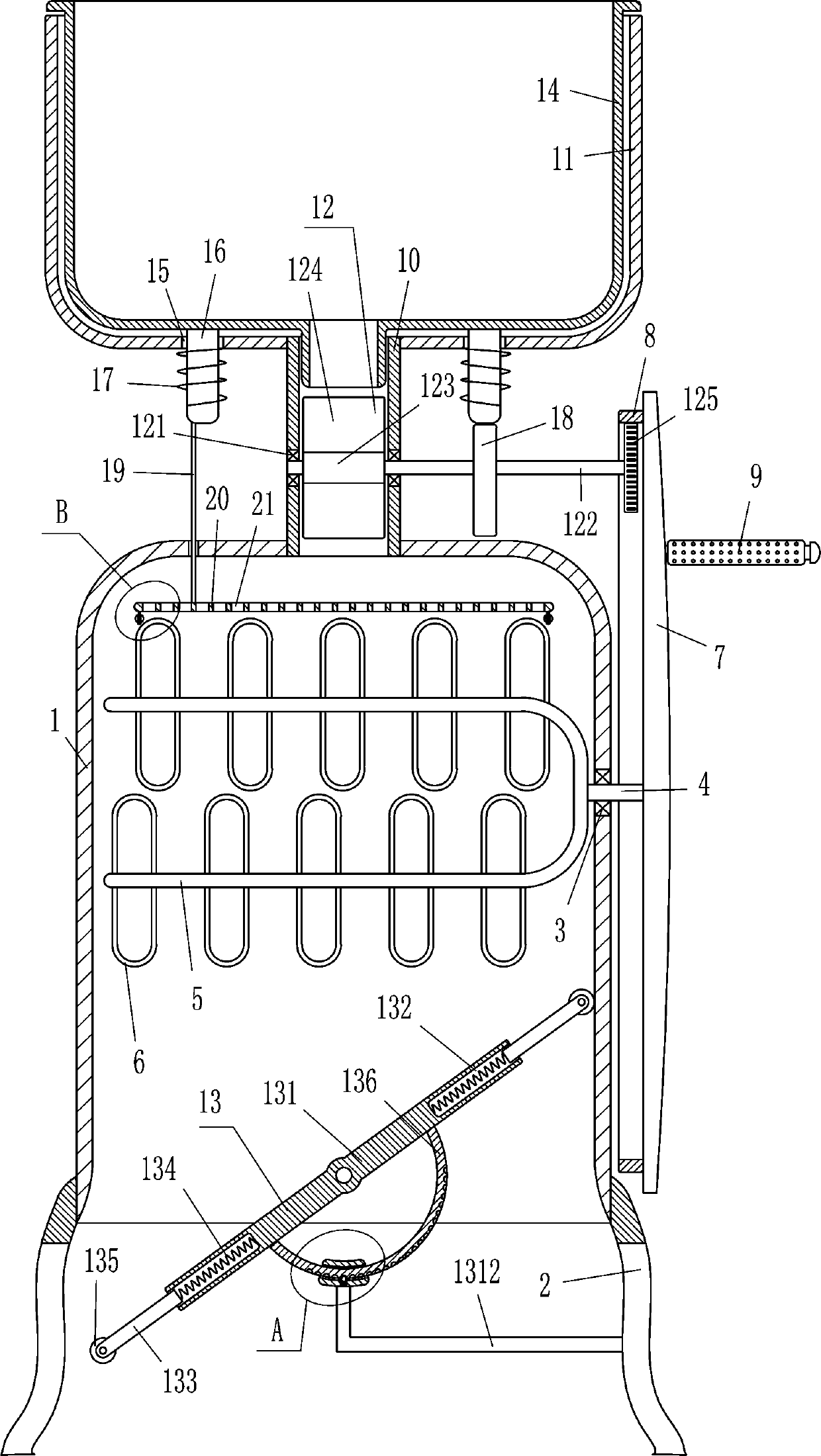

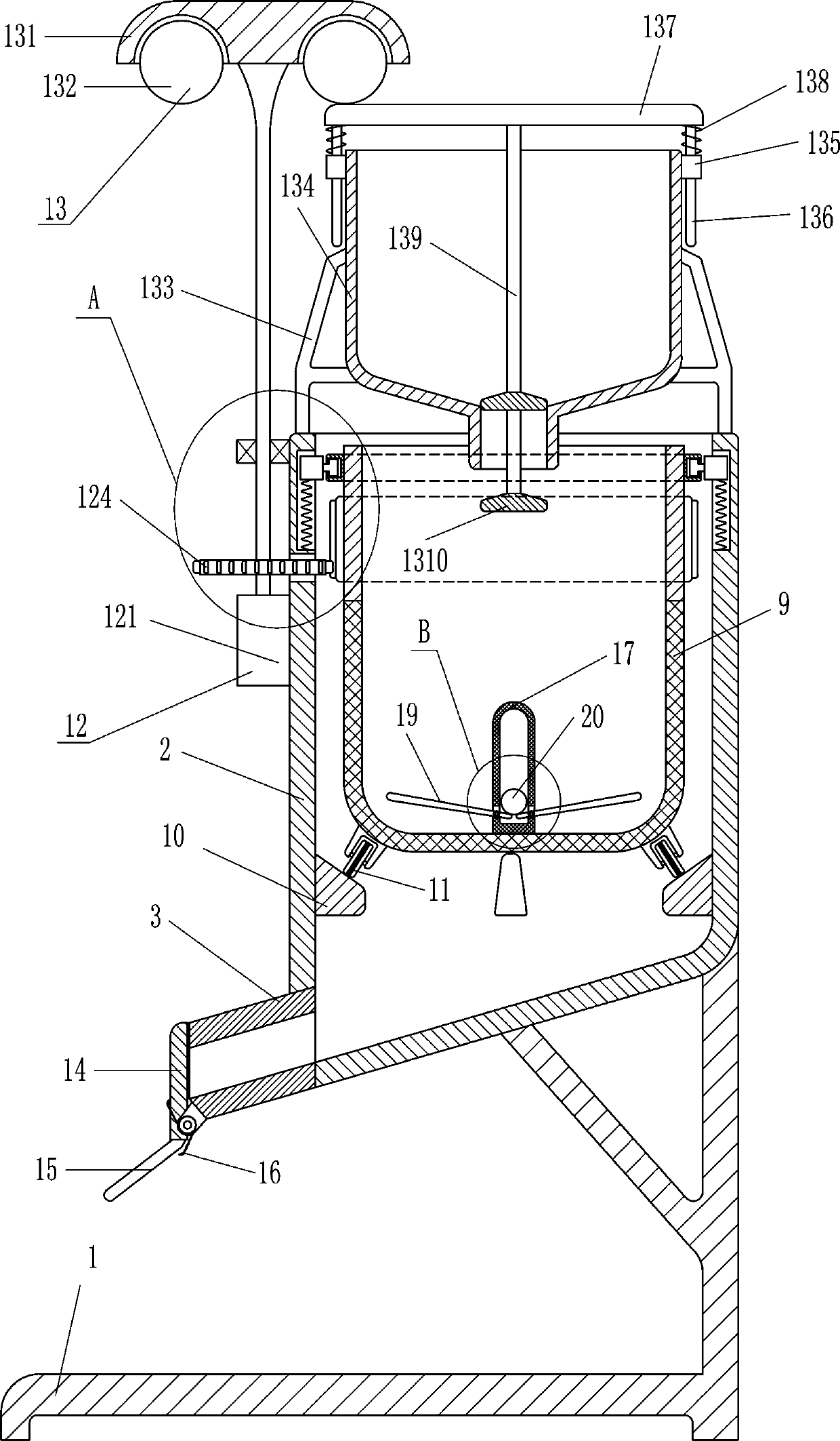

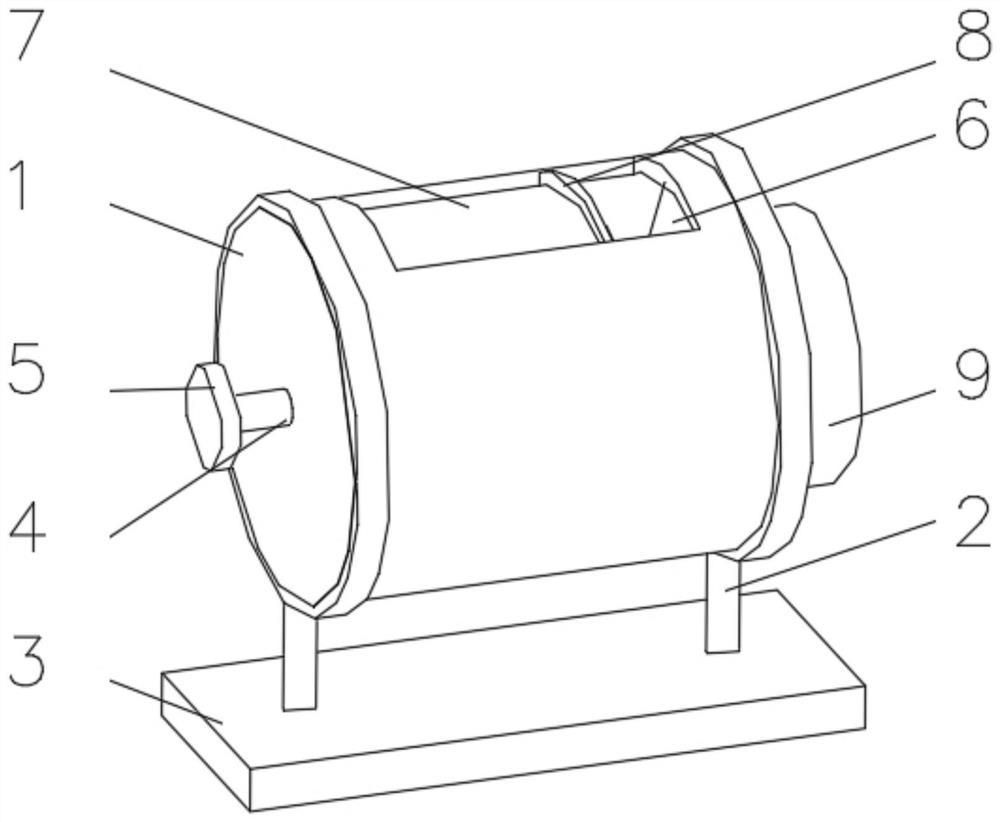

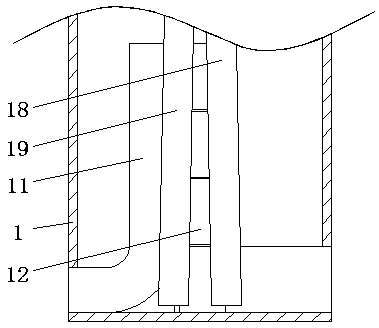

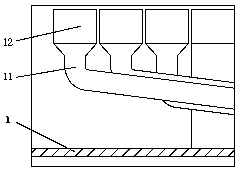

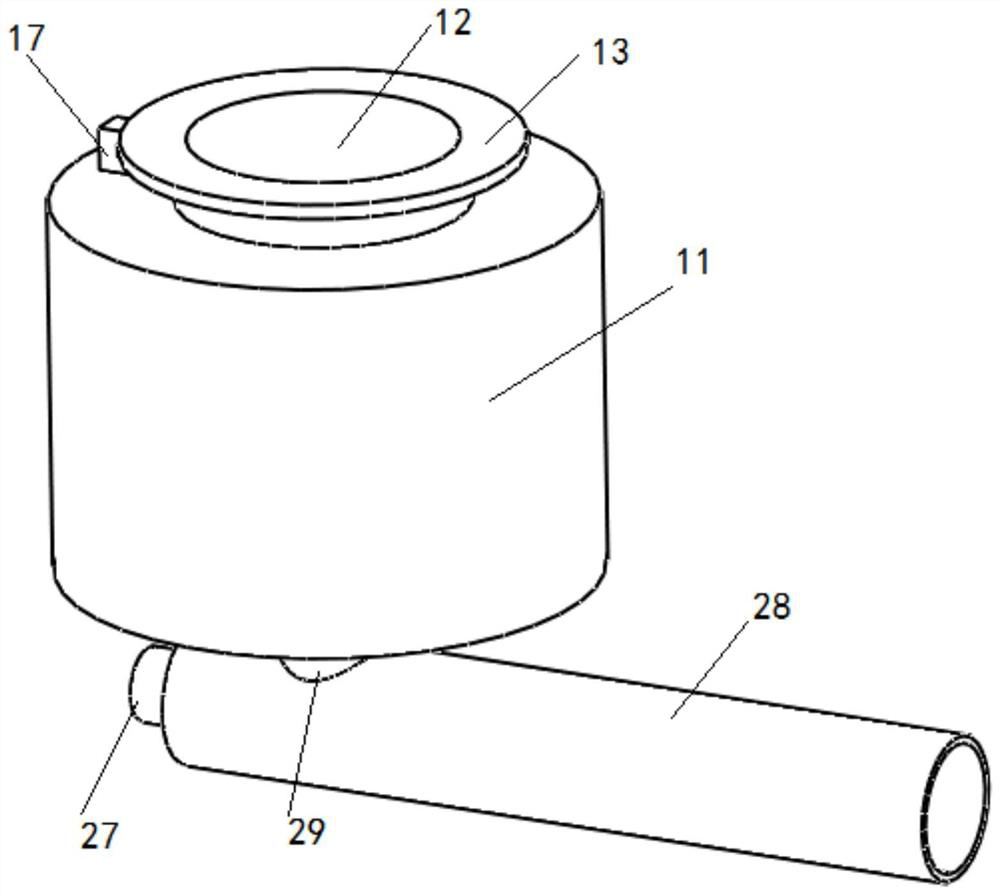

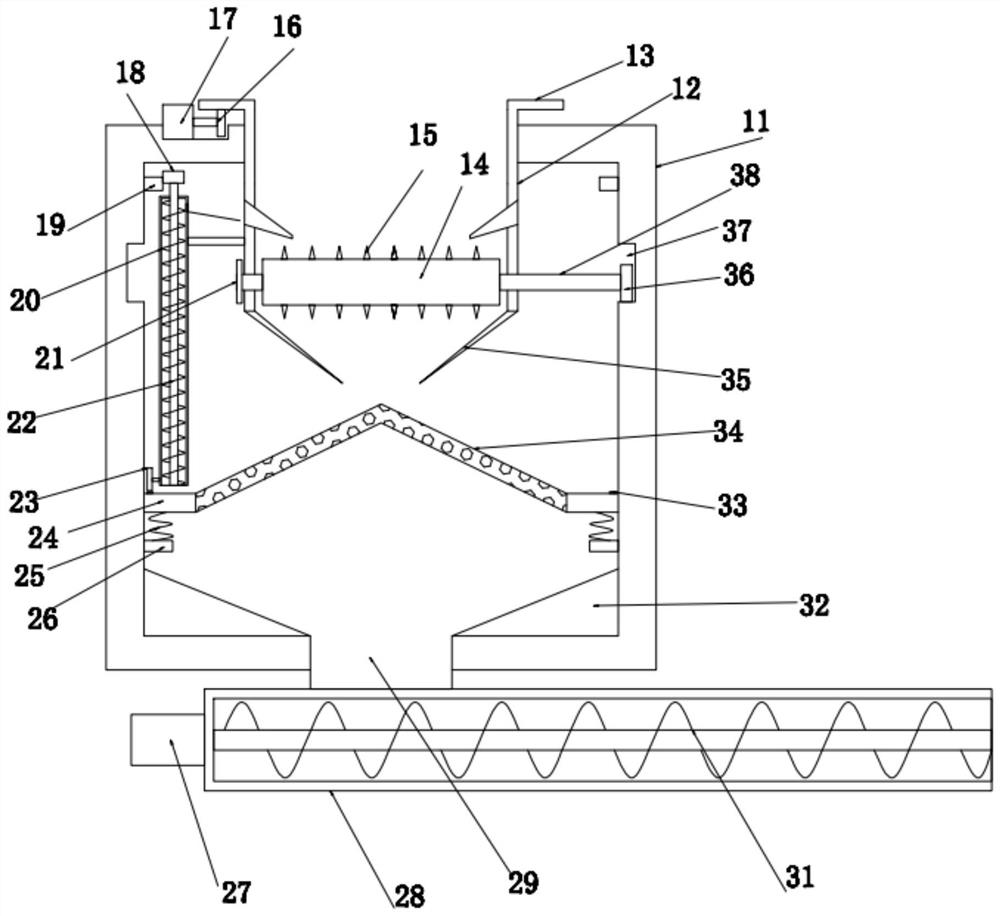

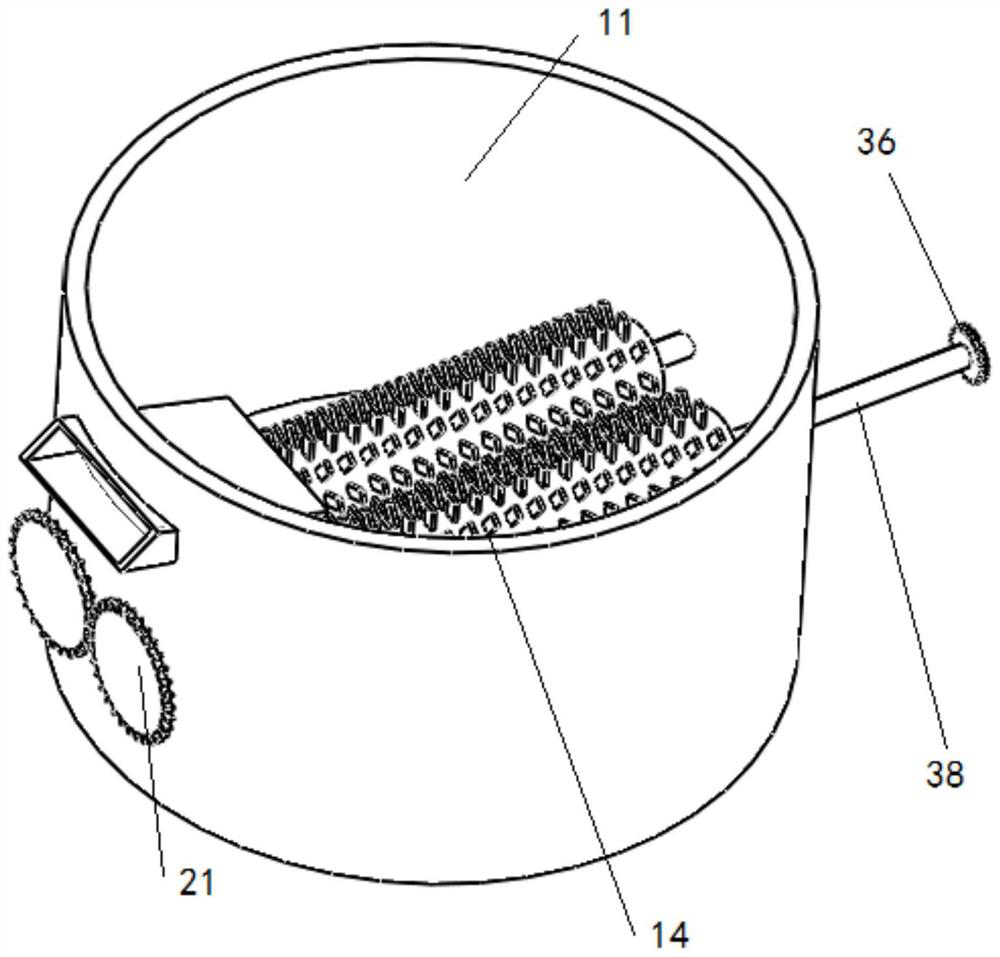

Sesame threshing machine

InactiveCN109644690ASpeed up the efficiency of knocking downAvoid affecting follow-up workThreshersSesamum orientalePulp and paper industry

The invention relates to a threshing machine, in particular to a sesame threshing machine. By the sesame threshing machine, sesame stalks can be thrown manually to avoid sour pain of arms, the workingefficiency is high, and the circumstance that sesames are splashed randomly to cause waste is avoided. According to the technical scheme, the sesame threshing machine comprises a frame, supporting legs, a bearing block, a rotating shaft, a barrel, a volute spiral spring, an n-shaped rod, an annular block, a vertical rod, a u-shaped rod, a wedge-shaped block, a first spring and the like; and the lower portions of the left side surface and the right side surface of the outside of the frame are fixedly connected with the supporting legs, the middle of the bottom of the frame is fixedly connectedwith the bearing block in an embedded manner, the rotating shaft is connected with the bearing in the bearing block, and a driving device is arranged between the bottom end of the rotating shaft andthe left side of the bottom of the outside of the frame. the sesame stalks are placed in a placement hole, by stepping on a pedal plate, the u-shaped rod forwards and reversely rotates alternately tothrown away sesames from the sesame stalks, the working efficiency is high, the circumstance that the sesame stalks are manually thrown to throw away the sesame is not required, and the circumstance that follow-up operation is affected by sour pain of the arms can further be avoided.

Owner:陈美凤

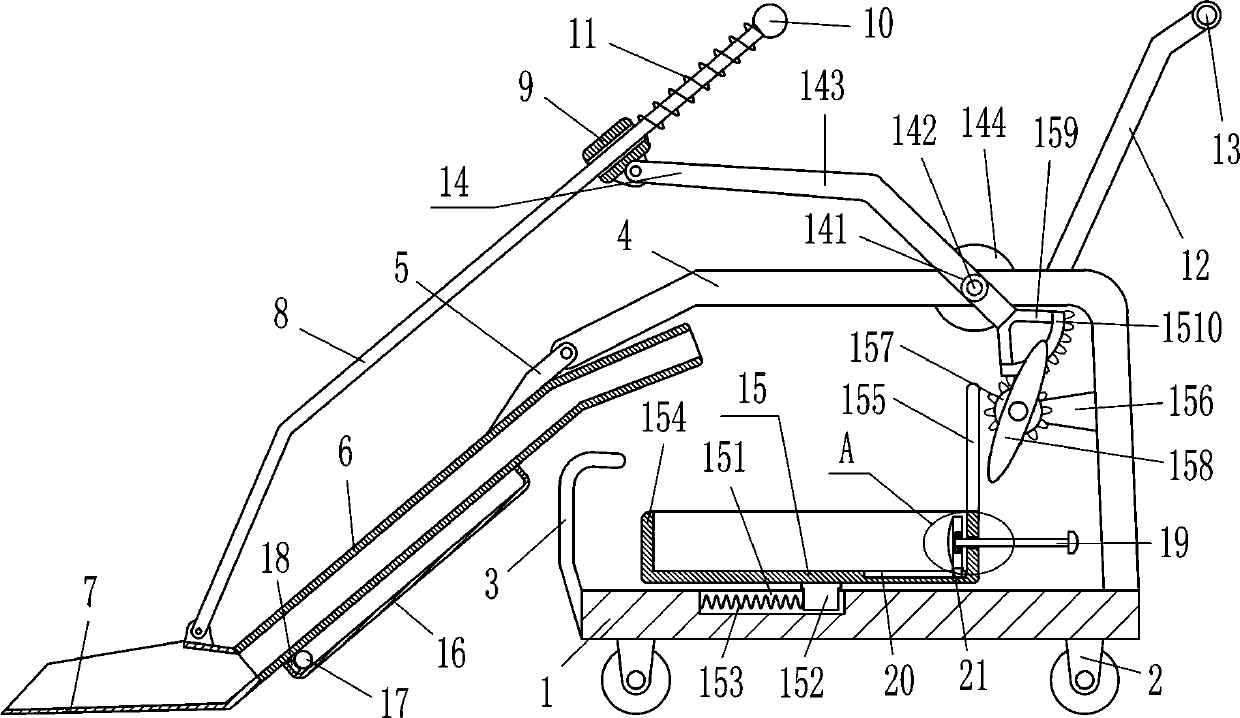

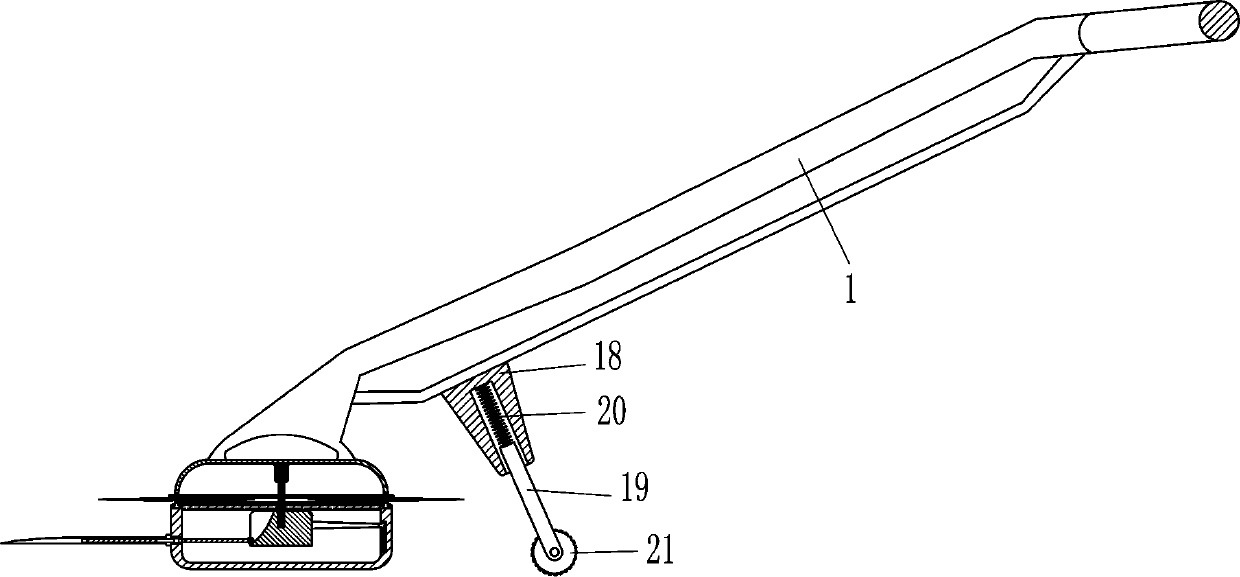

Bulk sand barrel loader

ActiveCN110027918AAvoid affecting follow-up workPrevent fallingConveyorsLoading/unloadingEngineeringDrive motor

The invention relates to a barrel loader, in particular to a bulk sand barrel loader. The bulk sand barrel loader aims at achieving the technical effects of being capable of replacing manual work to pour sand into a sand charging barrel, avoiding arm soreness, saving labor, and being capable of shaking the sand charging barrel to smooth the sand. According to the technical scheme, the bulk sand barrel loader comprises a bottom plate, wheels, an inverted-L-shaped baffle plate, an inverted-L-shaped frame, a connecting rod, a movable pipe, a bucket, a movable rod, a sliding sleeve, a limiting ball and the like, the wheels are symmetrically arranged on the left side and the right side of the bottom of the bottom plate, the inverted-L-shaped baffle plate capable of preventing the sand chargingbarrel from falling off is arranged on the left side surface of the bottom plate, the inverted-L-shaped frame is fixedly connected to the right side of the top of the bottom plate, and the connectingrod is hinged to the left end of the inverted-L-shaped frame. According to the sand loading barrel, sand is shoveled up by the bucket, a driving motor is started to rotate forwards, the bucket can move upwards to be in an inclined state, the sand is poured into the sand charging barrel through the movable pipe, people do not need to continuously shovel the sand into the sand charging barrel by using a shovel, labor is saved, and the problem that arm soreness influences subsequent work is avoided.

Owner:威海高新园区运营管理有限公司

Ceramic tile quality detection device

The invention relates to a detection device, in particular to a ceramic tile quality detection device, and aims to provide the ceramic tile quality detection device which can replace people to carry out quality detection on ceramic tiles, is convenient to operate and high in working efficiency and can collect broken ceramic tiles. The ceramic tile quality detection device comprises a base, a transverse plate and a fixed plate, wherein a vertical plate is installed in the middle of one side of the base; the transverse plate is mounted between one side of the base and the middle part of one sideof the vertical plate; and the fixed plate is fixedly connected to one side, far away from the base and the vertical plate, of the transverse plate. According to the ceramic tile quality detection device, a motor is started and drives a conveying mechanism to rotate forwards, the conveying mechanism rotates forwards to drive the ceramic tiles to move backwards to make contact with an ejecting mechanism, at the moment, the conveying mechanism drives the ejecting mechanism to operate, the ejecting mechanism operates to drive the ceramic tiles to move upwards to proper positions to be disengagedfrom the ejecting mechanism, and the ceramic tiles fall downwards under the action of gravity to be subjected to quality detection.

Owner:佛山市科维骏机电设备有限公司

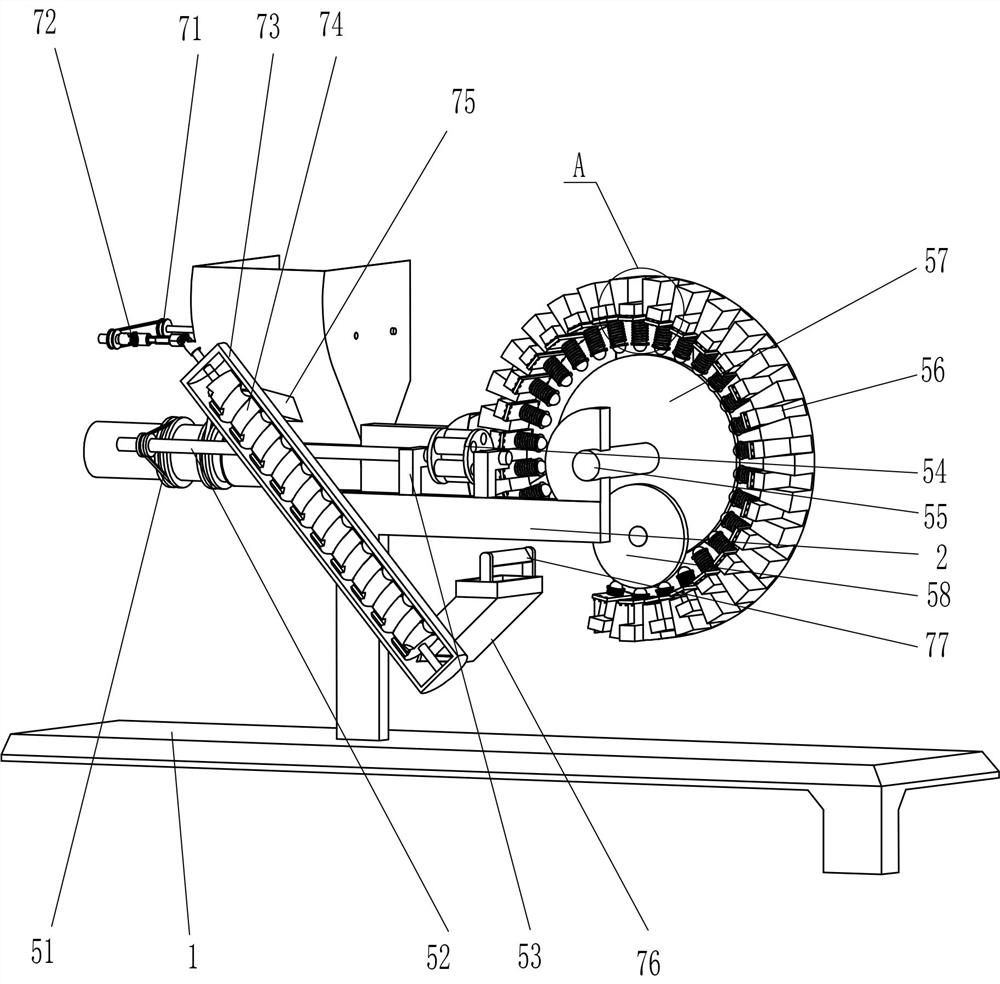

Oblique-to-flat self-return feeding device

PendingCN109677852ASports effectsAvoid affecting follow-up workControl devices for conveyorsJigging conveyorsMechanical engineeringEngineering

Owner:昆山兴基德自动化设备有限公司

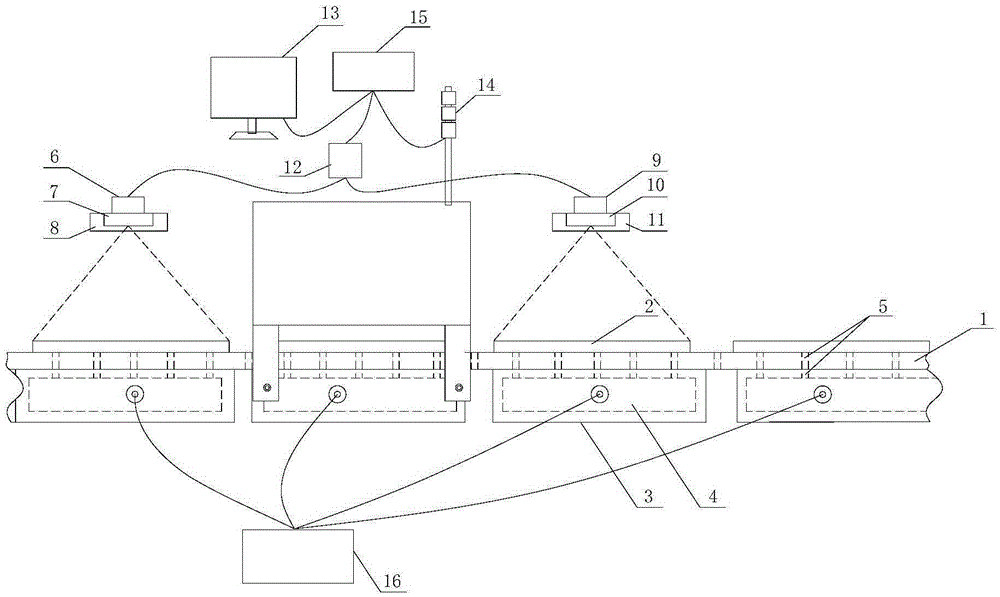

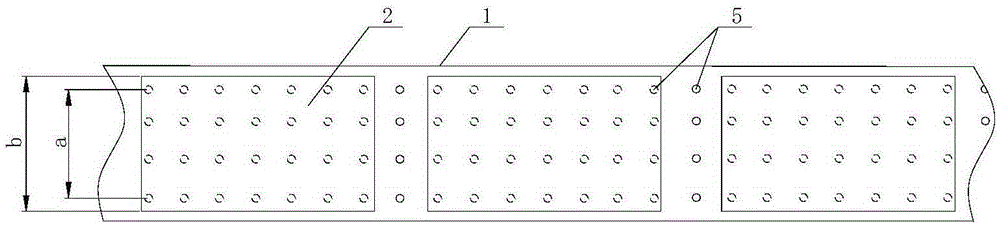

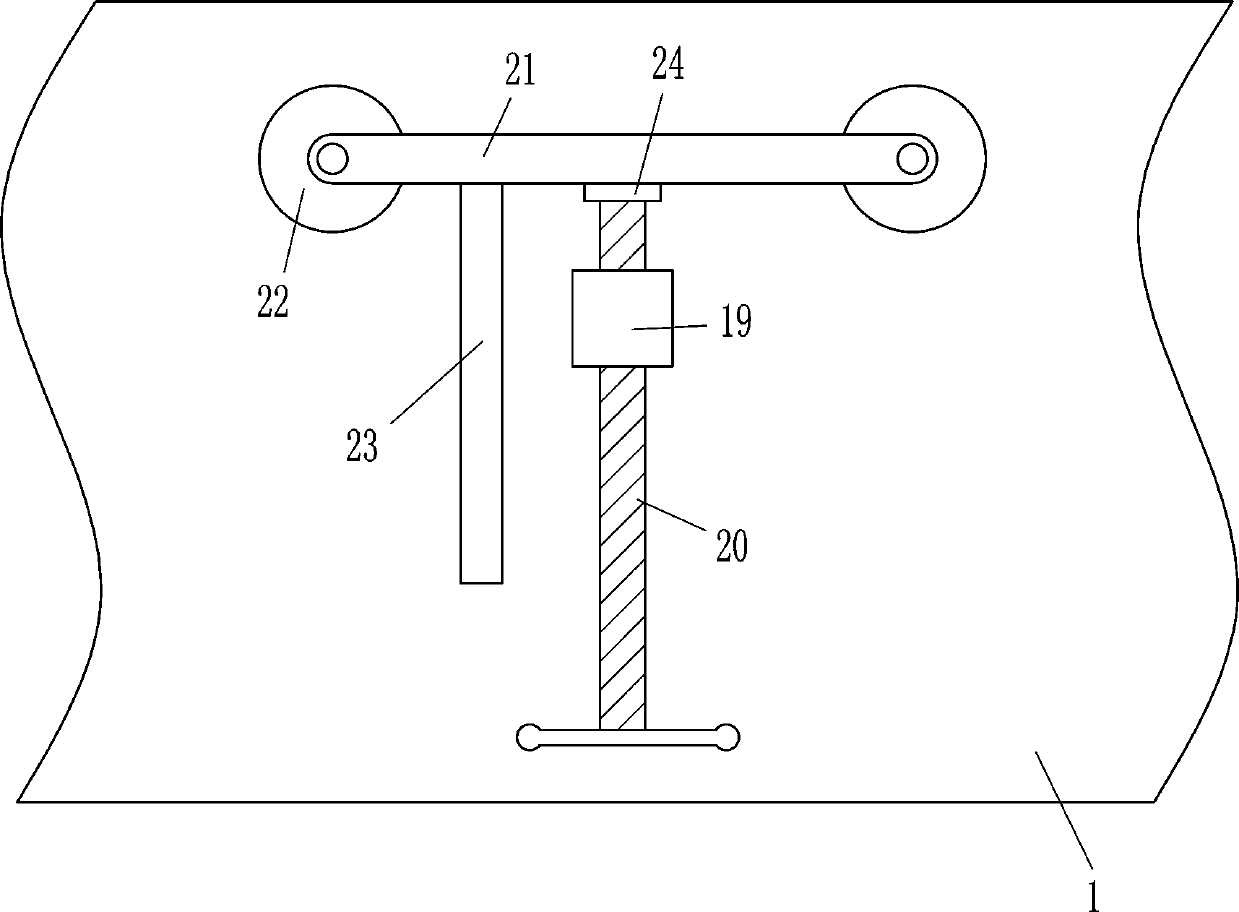

Pressure type solar panel cracking detection mechanism

InactiveCN105428463ATimely processingAvoid affecting follow-up workSemiconductor/solid-state device testing/measurementFinal product manufactureDisplay deviceAutomatic testing

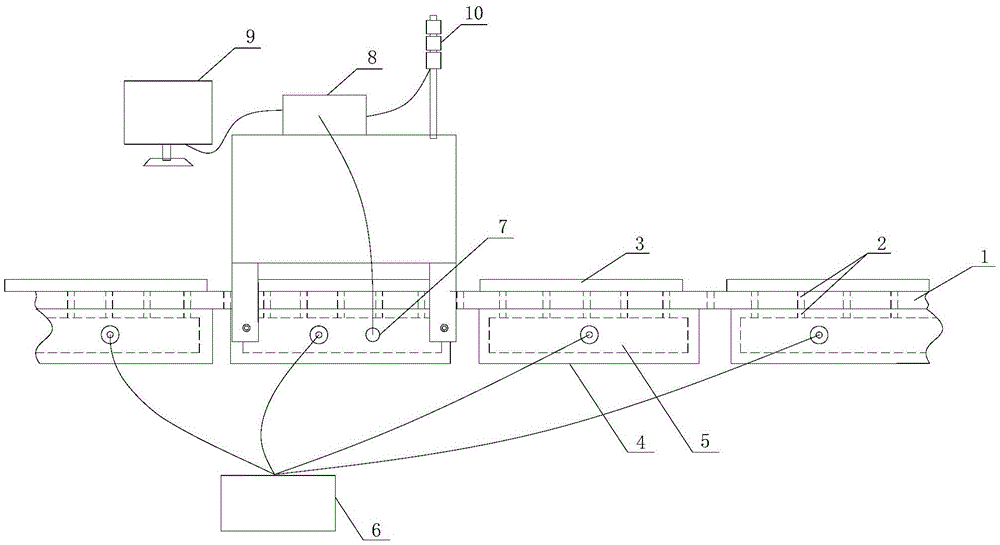

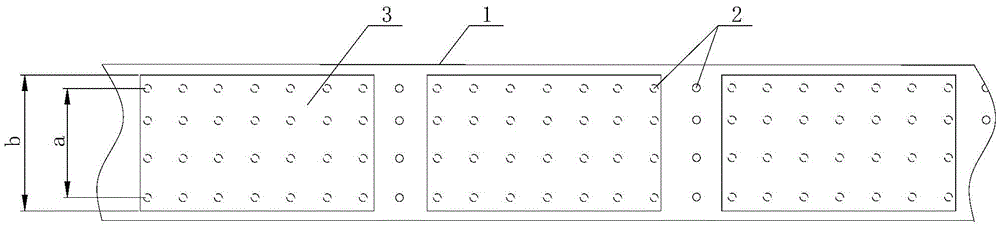

The invention provides a pressure type solar panel cracking detection mechanism. The pressure type solar panel cracking detection mechanism comprises a conveying belt, a plurality of vacuum adsorption assemblies and a pressure detection assembly; a plurality of rows of through holes are formed in the conveying belt; the distance between two rows of through holes at the outmost side is smaller than the length of sides of solar panels at the width direction of the conveying belt; each vacuum adsorption assembly comprises an adsorption plate located below the conveying belt; a cavity is formed in the adsorption plate; a plurality of through holes communicated with the cavity and the outside are formed at the upper end of the adsorption plate; the pressure detection assembly includes pressure sensors, a measuring circuit and a display device; the pressure sensors are arranged on the inner walls of the cavities; and the pressure sensors are in line connection with the measuring circuit and the display device outside the cavities successively. According to the pressure type solar panel cracking detection mechanism of the invention, the pressure sensors are adopted to monitor pressure change in the cavities in the adsorption plates, and therefore, automatic detection of the cracking of the solar panels can be realized, and the reliability of a welding system can be improved, and influence on downstream processes can be avoided, and work efficiency can be improved.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

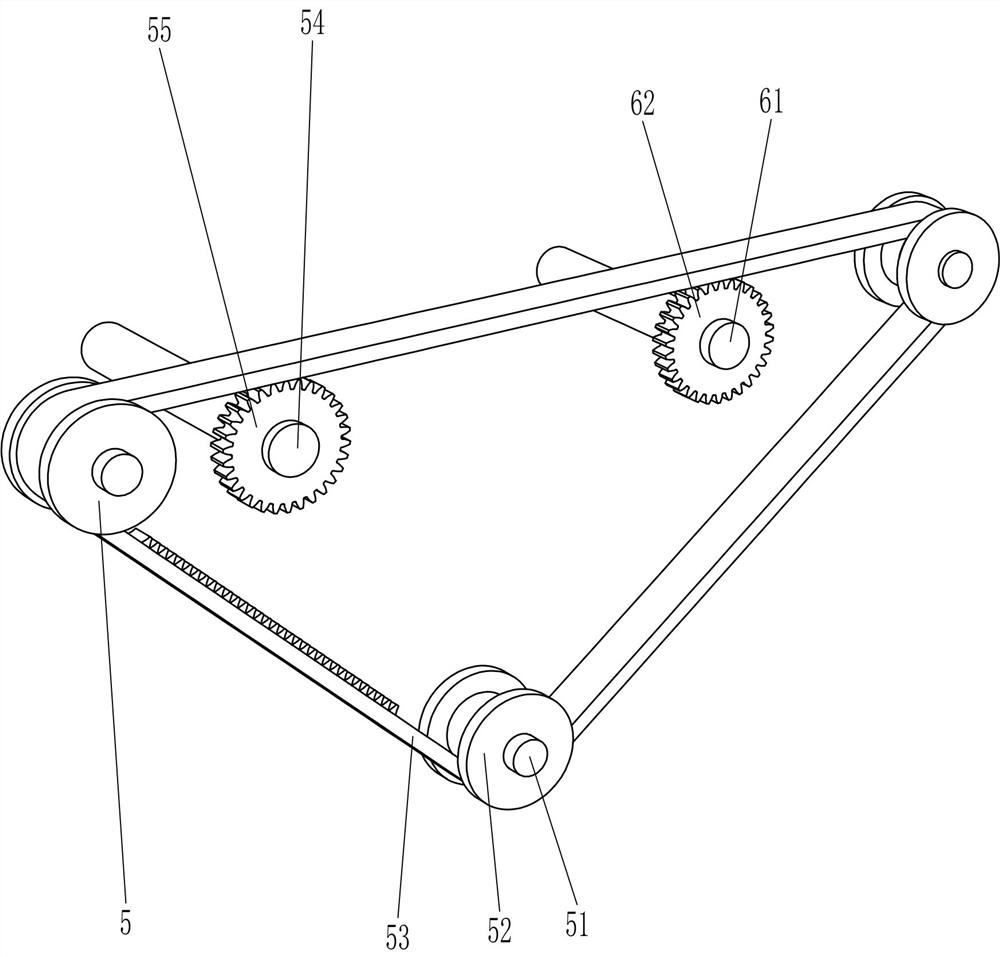

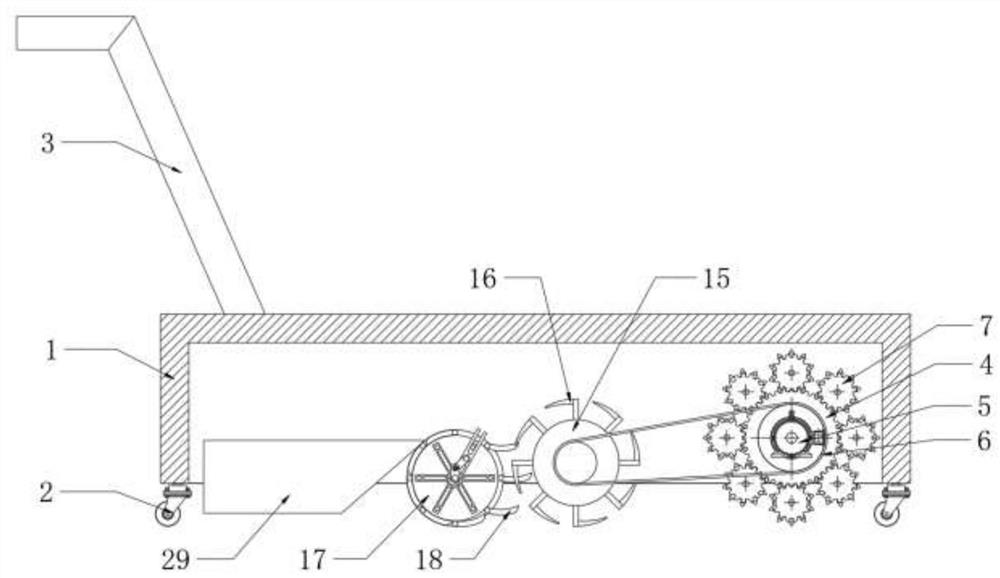

Temporary marking machine for stadiums

ActiveCN109794057AAvoid accumulationAvoid affecting useSki bindingsWater-skiingGear wheelEngineering

The invention relates to a marking machine, in particular to a temporary marking machine for stadiums. The technical problem of the invention is to provide a temporary marking machine for stadiums, which has no need for a user to make markings with limestone powder, which prevents bending of markings from affecting usage, which allows multiple markings to be made at the same time, and which has high working efficiency. The temporary marking machine for stadiums comprises a bottom plate, a first roller, a holding basket, a piston, a push handle, a second roller, a first bearing block, a spindle, a screw conveyer shaft, a discharge pipe, a first bevel gear and the like; the first roller is mounted on the right of the bottom of the bottom plate; the holding basket to store limestone powder may be mounted on the left of the top of the bottom plate; the piston is arranged on the right side of the top of the holding basket. The limestone powder is poured into the holding basket; the machineherein is pushed to move at a marking position; the limestone power falls on the marking position to form a marking; holding the limestone powder manually to make markings is not required; it is prevented that bending of the markings affects usage.

Owner:ANHUI QIANTONG EDUCATION MFG

Visual detection mechanism for crack of solar cell panel

InactiveCN105403573AImprove accuracyImprove detection efficiencyOptically investigating flaws/contaminationProduction lineData acquisition

The invention provides a visual detection mechanism for crack of a solar cell panel. The visual detection mechanism comprises a conveyor belt and a visual detection assembly. Solar cell panels are placed on the conveyor belt at an equal interval; the visual detection assembly comprises a first camera, first lens and first light source arranged over a solar cell panel about to enter a welding station, a second camera, second lens and second light source arranged over a solar cell panel having departed from the welding station, a data acquisition card, a display unit and an industrial control computer, wherein the first camera and the second camera are successively connected with the data acquisition card and the industrial control computer in a line connection manner, and the display unit is in line connection with the industrial control computer. The visual detection mechanism for crack of the solar cell panel employs combinations of the cameras, the lenses and the light sources to replace artificial detection of cracks on the solar cell panel, can effectively improve the detection speed and precision of a production line and prevents misjudgement and leak detection caused by fatigue of eyes of workers.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

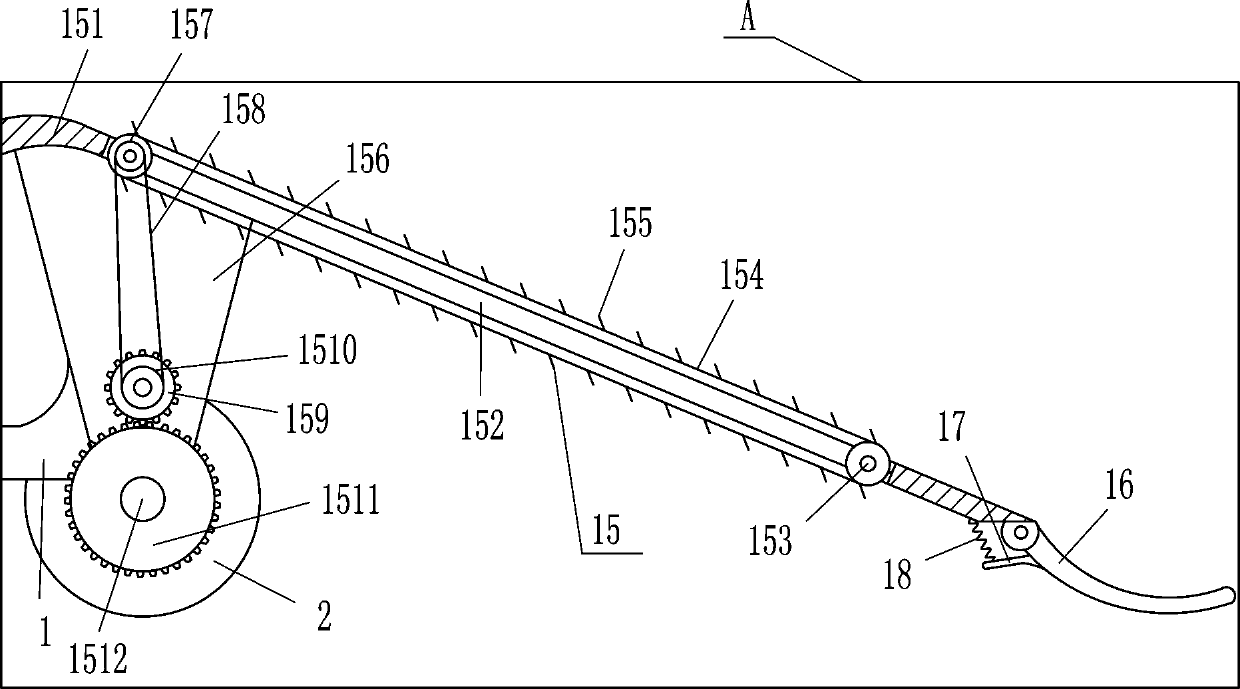

Garden roadside branch pruner

ActiveCN109892126AAvoid affecting follow-up workImprove work efficiencyCuttersCutting implementsDrive motorEngineering

The invention relates to a pruner, in particular to a garden roadside branch pruner. The technical purpose is to provide the garden roadside branch pruner which can make people prune branches more conveniently, saves more effort, does not need to stoop constantly, and avoids the situation that waist aches affect the follow-up work. According to the technical scheme, the garden roadside branch pruner comprises a bottom plate, wheels, a slanting rod, a handle, a frame, vertical sliding blocks, a vertical sliding rail and the like; the left and right sides of the bottom of the bottom plate are provided with the wheels respectively, the middle of the top of the bottom plate is fixedly connected with the frame, and the frame is internally provided with the vertical sliding rail playing a guiding role. The garden roadside branch pruner has the advantages that a driving motor is started, so that a first cutter moves vertically; then the pruner is pushed to move rightward along a flower nursery, so that the first cutter cooperates with a second cutter to prune the branches, a person does not need to hold scissors by hand to prune the branches, more effort is saved, the work efficiency is also high, stooping is not needed, and it is avoided that the waist aches affect the follow-up work.

Owner:阜南县富昌恒业工艺品有限公司

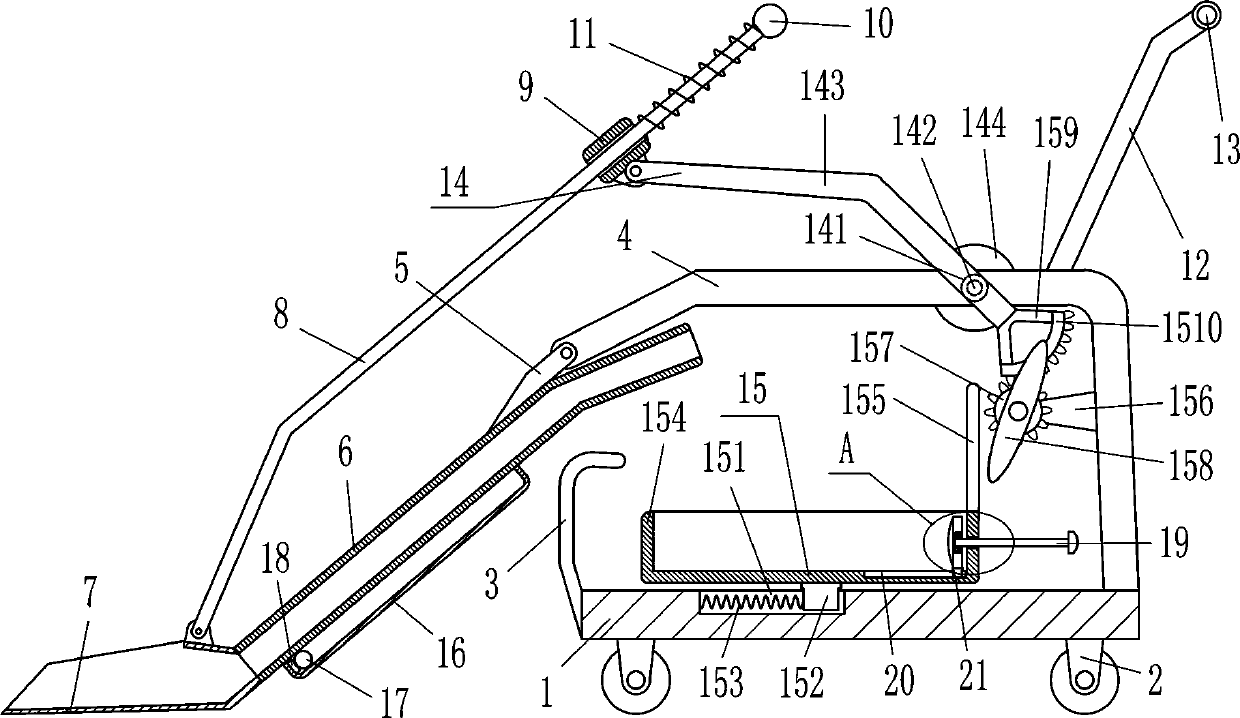

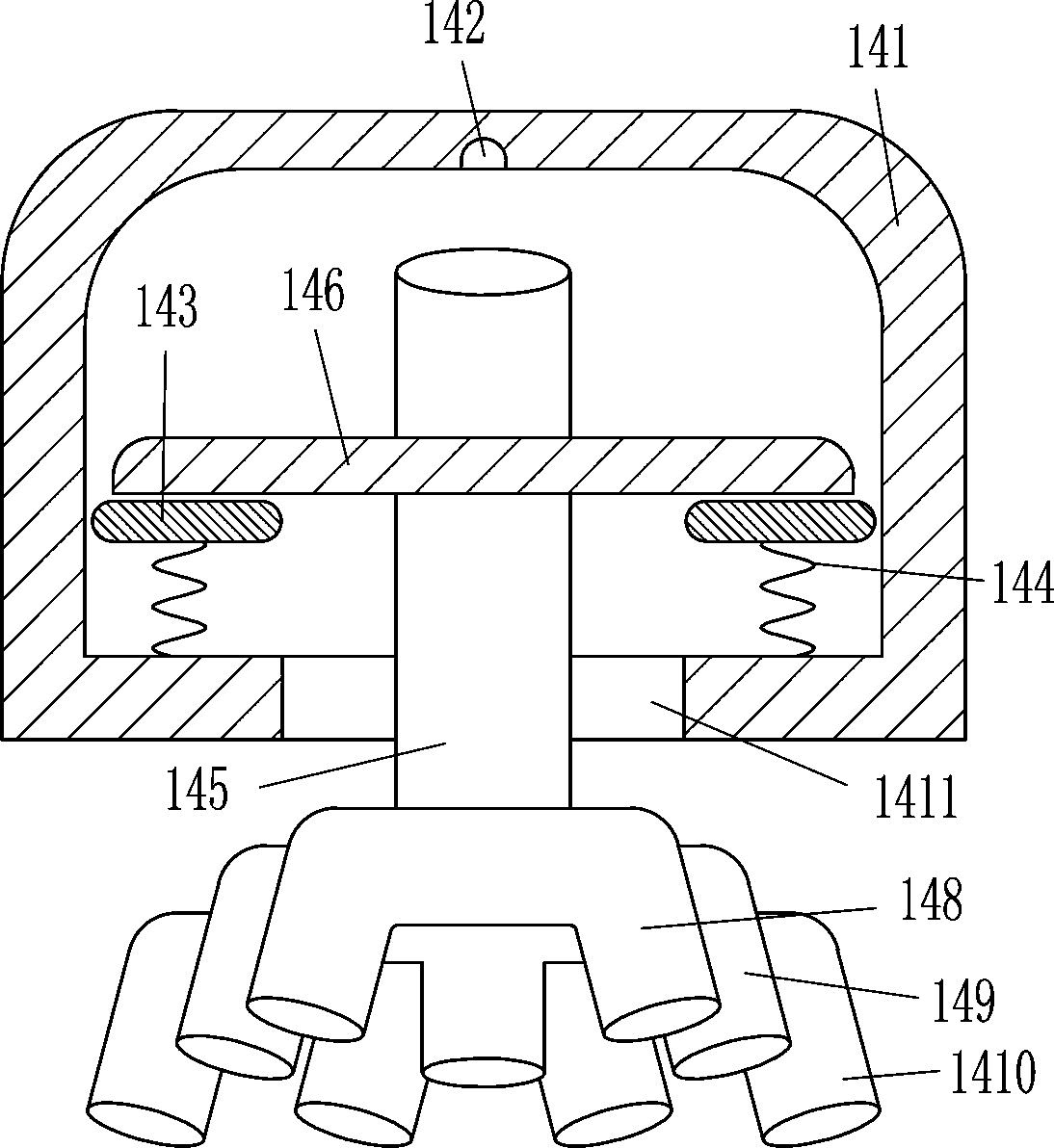

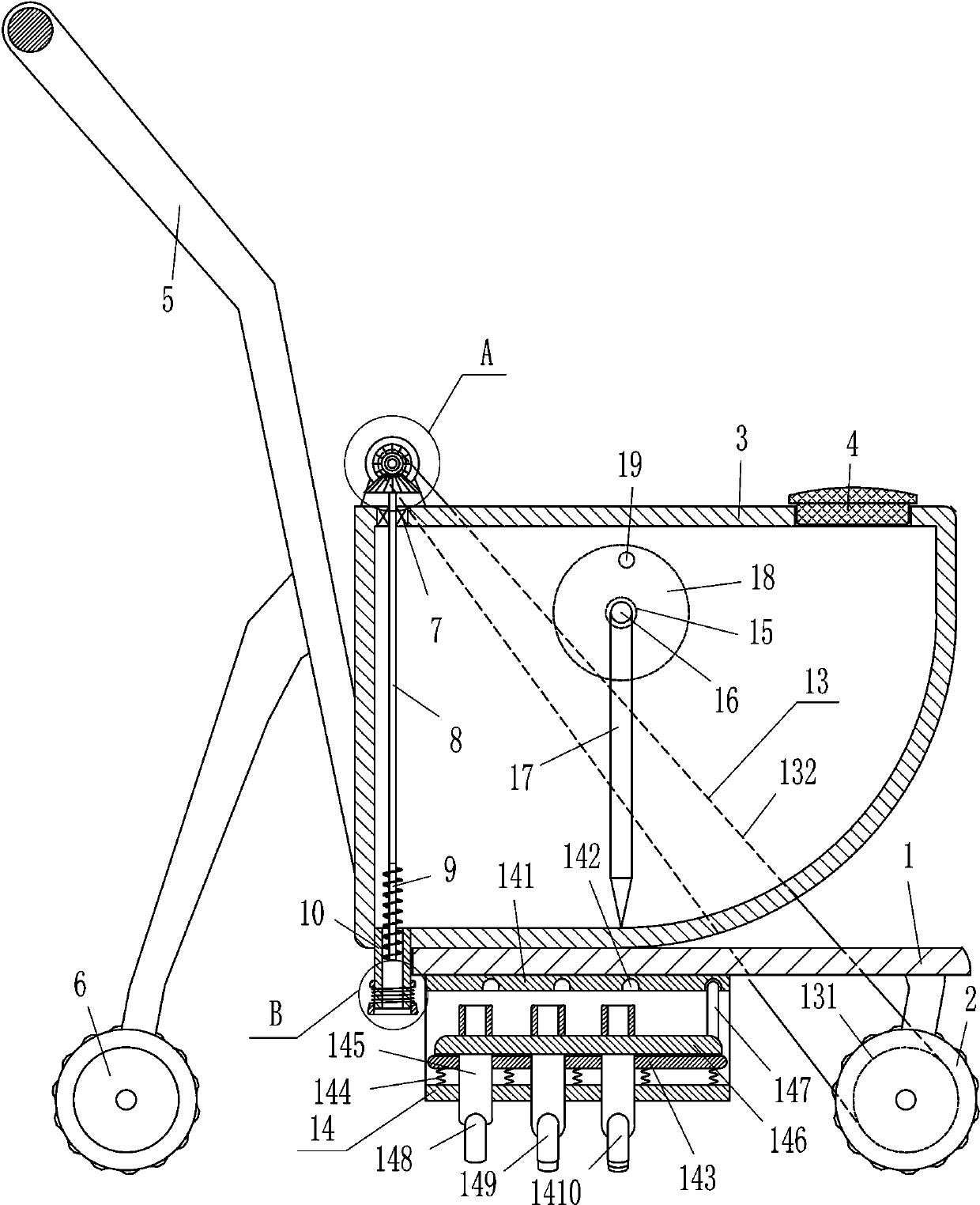

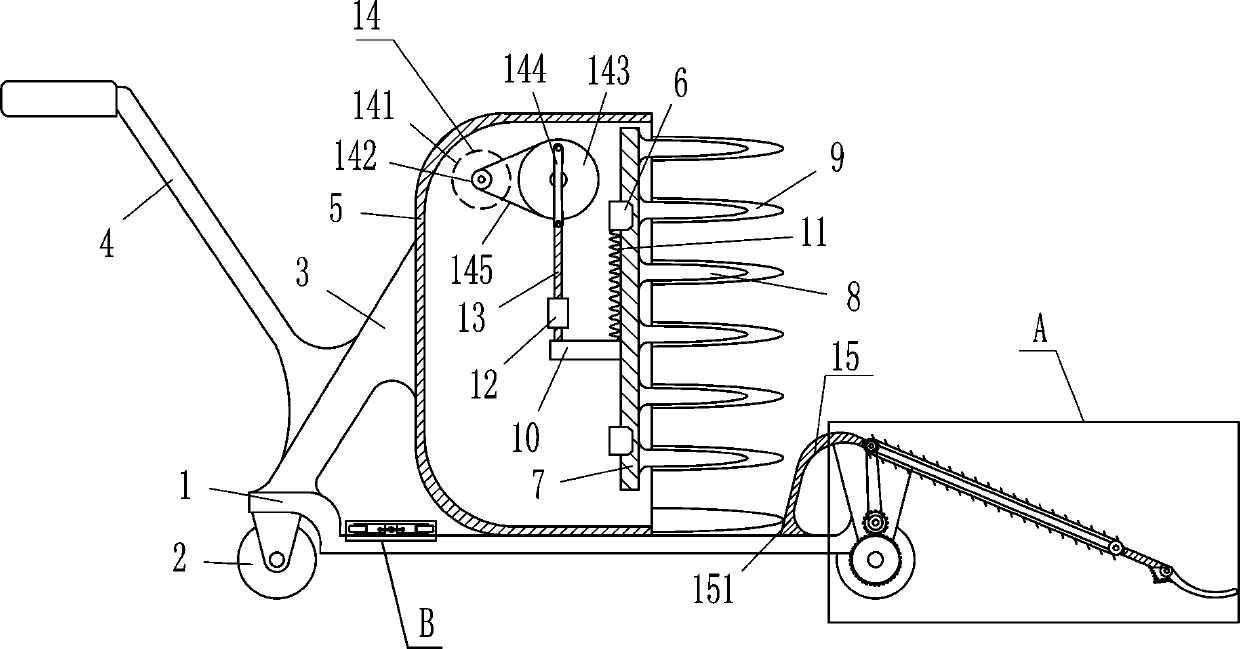

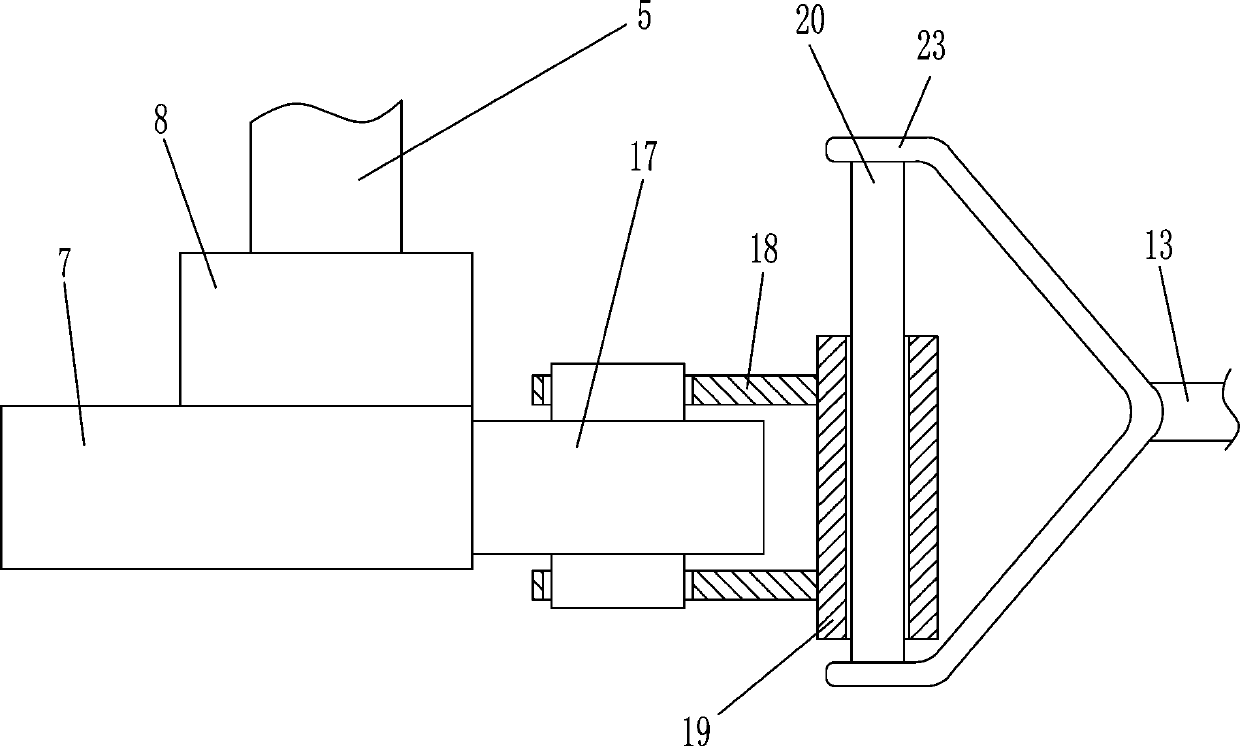

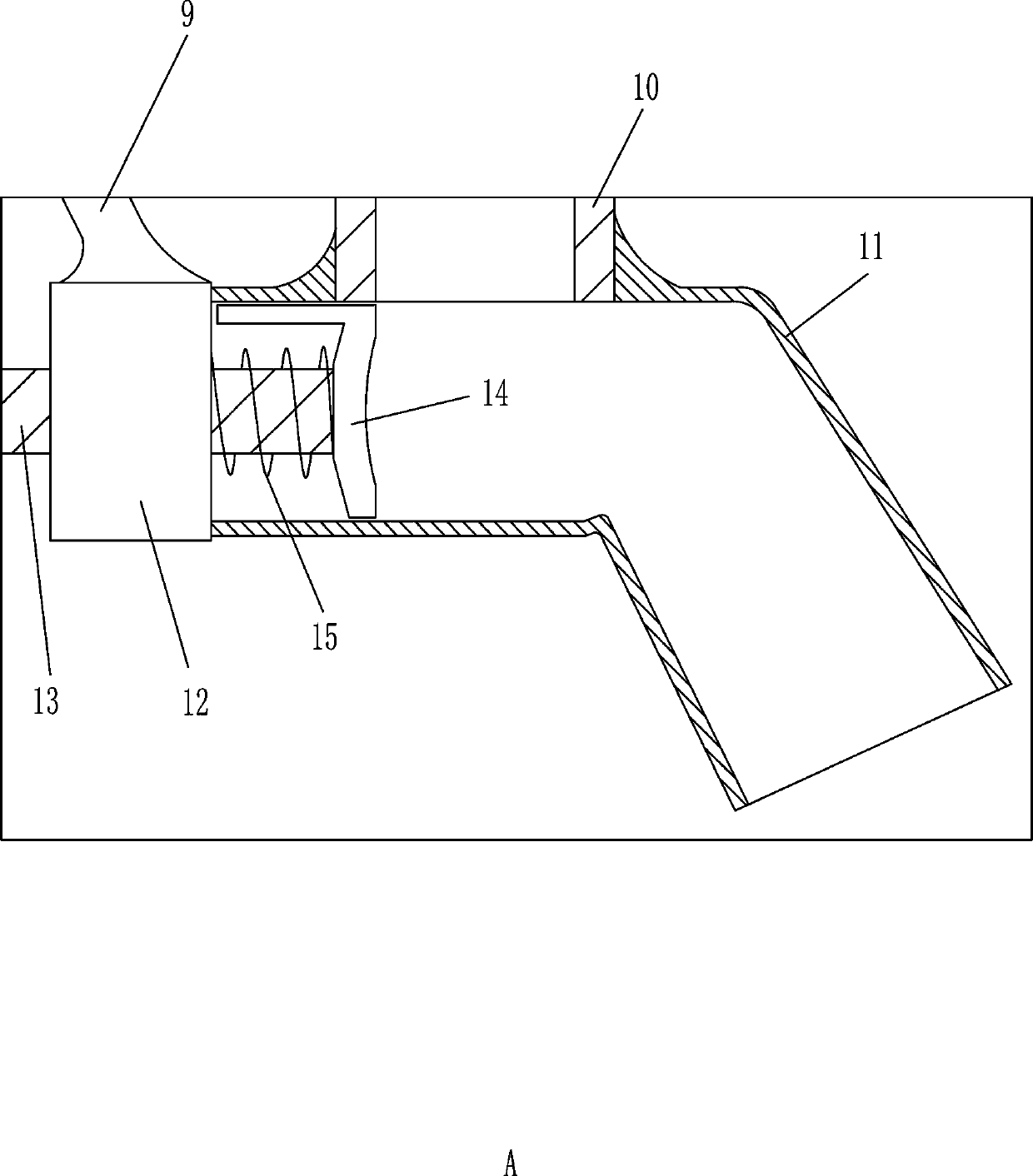

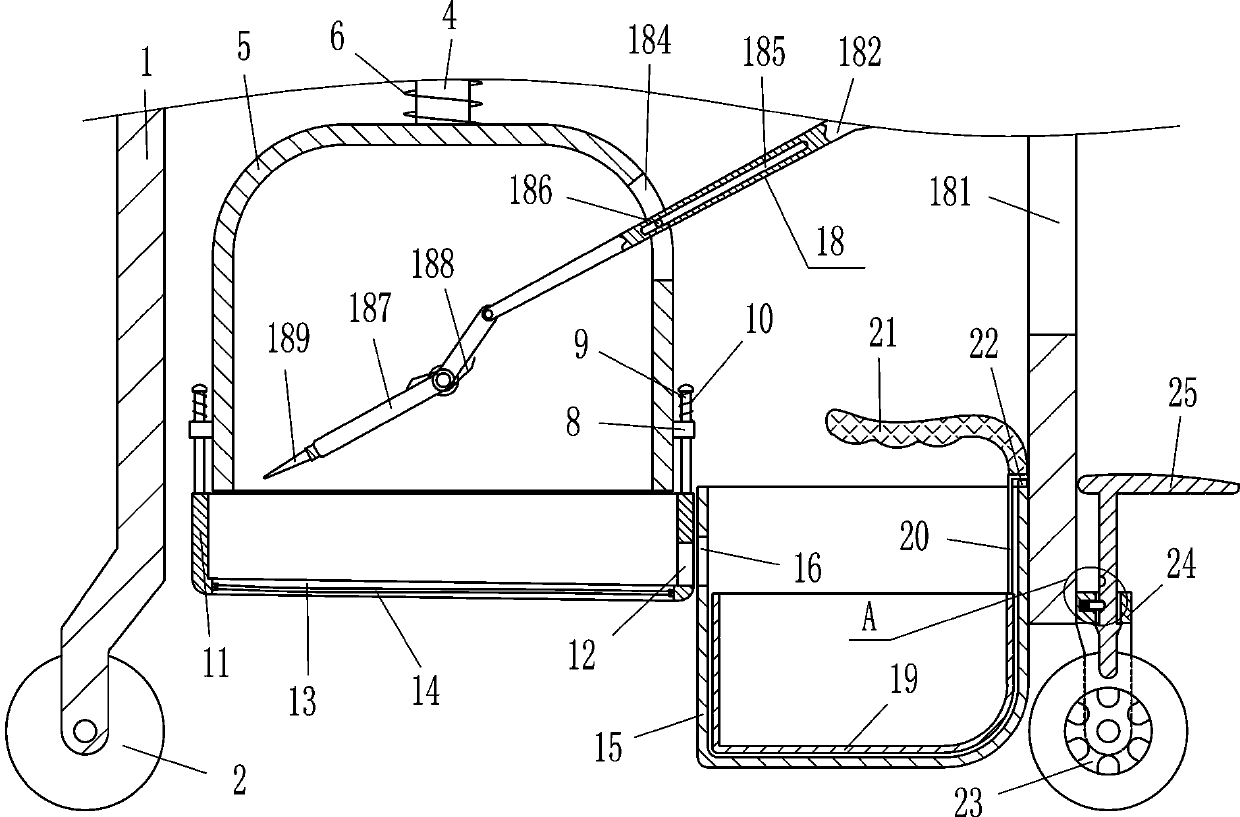

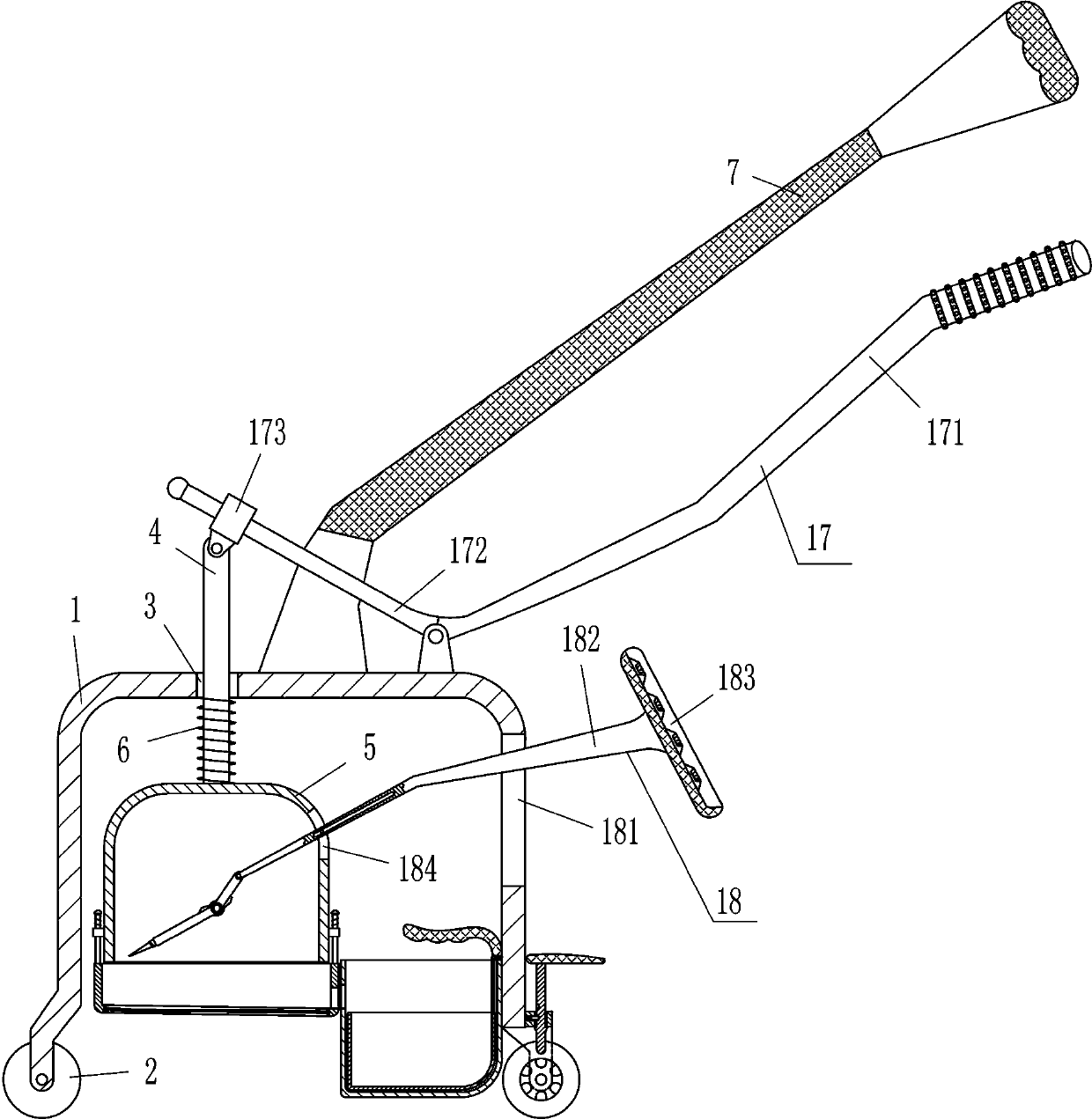

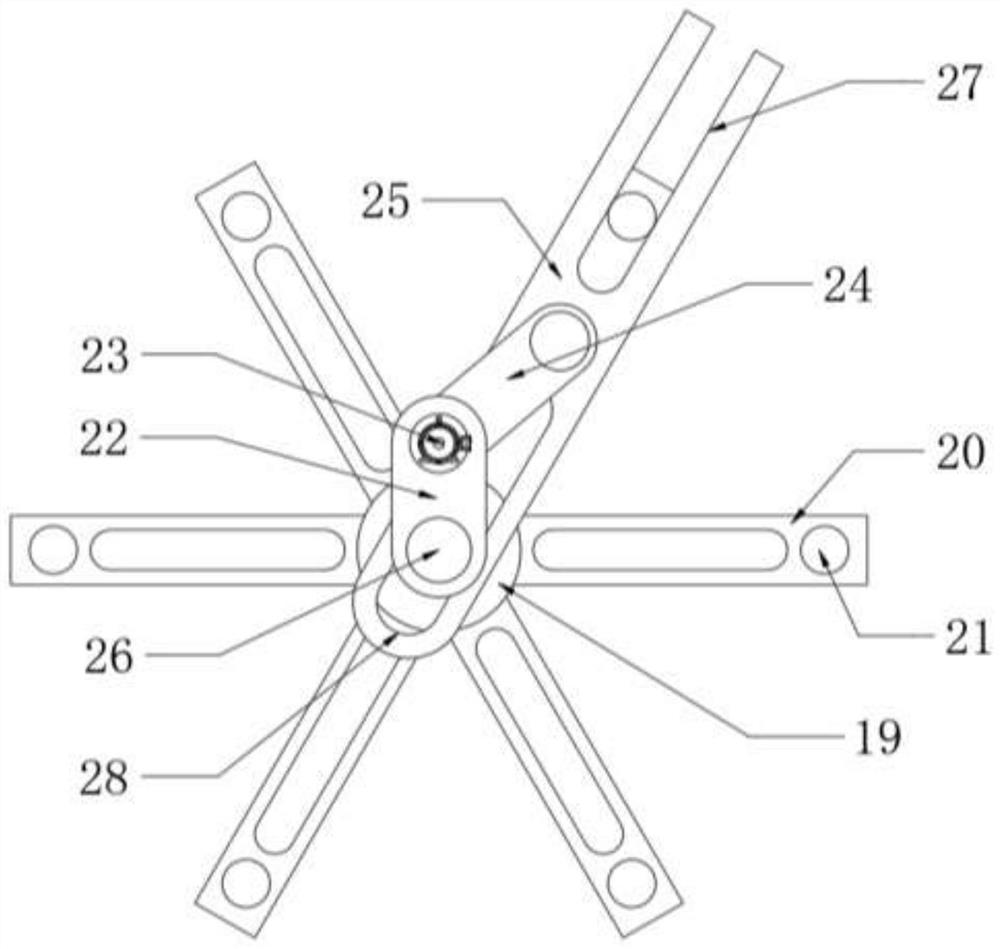

Handcart type potato seeder

InactiveCN110419302AAvoid affecting follow-up workSeed depositing seeder partsBroadcast seedersEngineeringCam

The invention relates to a seeder, in particular to a handcart type potato seeder, which can dig into soil to sow seeds in a convenient and labor-saving manner and can avoid affecting follow-up work due to pain in the waist caused by continuous bending down. The technical scheme includes: the handcart type potato seeder comprises a mounting frame, reinforcing ribs, a funnel, a push handle, a rotating shaft, coarse-textured wheels, a first cam, a second cam, a first supporting rod, a feeding pipe and the like, wherein the feeding pipe is connected to the middle of the bottom of the funnel and communicated into the funnel. In application of the handcart type potato seeder, potato seeds are placed in the funnel and then drop into a bell-mouth bending pipe, a push plate is driven to move leftand right continuously when the handcart type potato seeder is pushed leftwards, and further the push plate moves rightwards to push the potato seeds to drop into soil to complete the sowing, the wayof sowing the potato seeds by continuous bending down is omitted, affecting the follow-up work due to pain in the waist is avoided, and great convenience is brought to users.

Owner:罗煊

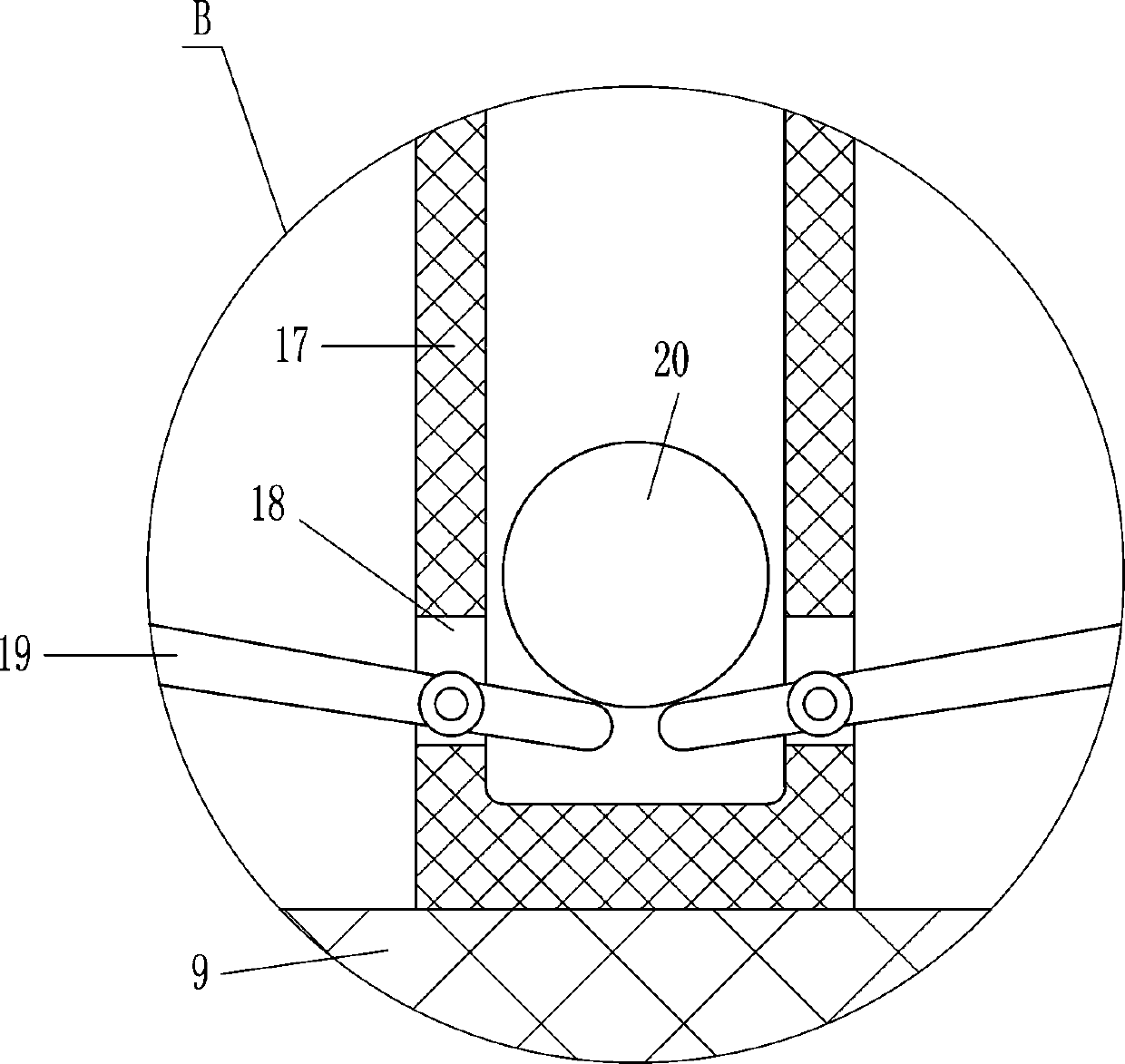

Intermittent discharging device

ActiveCN110683377ANot easy to damageAvoid affecting follow-up workLoading/unloadingClassical mechanicsPipe

The invention relates to a discharging device, in particular to an intermittent discharging device. The intermittent discharging device can intermittently drop spherical materials out for manual treatment, continuous bowing is not needed, the influence of waist arch on subsequent work is avoided, and the phenomenon that the spherical materials are prone to falling to ground so as to be damaged isavoided. The intermittent discharging device comprises a base and the like, wherein the right side of the top of the base is fixedly connected with a supporting plate, and the left end of the supporting plate is fixedly connected with a discharging pipe. According to the device, an appropriate quantity of spherical materials are poured into a loading frame, the spherical materials fall into a hollow cylinder body through the discharging pipe, the spherical materials fall onto an L-shaped plate, the L-shaped plate drives the spherical materials to reversely rotate to the right side of a discharging port, the spherical materials fall into the discharging pipe through the discharging port, and then drop onto a workbench for being treated by workers, the spherical materials do no needed to betaken out from a collecting container by the workers in a continuous bowing mode, the subsequent work is prevented from being affected by the waist ache, and the phenomenon that the spherical materials are prone to falling to the ground so as to damaged is avoided.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

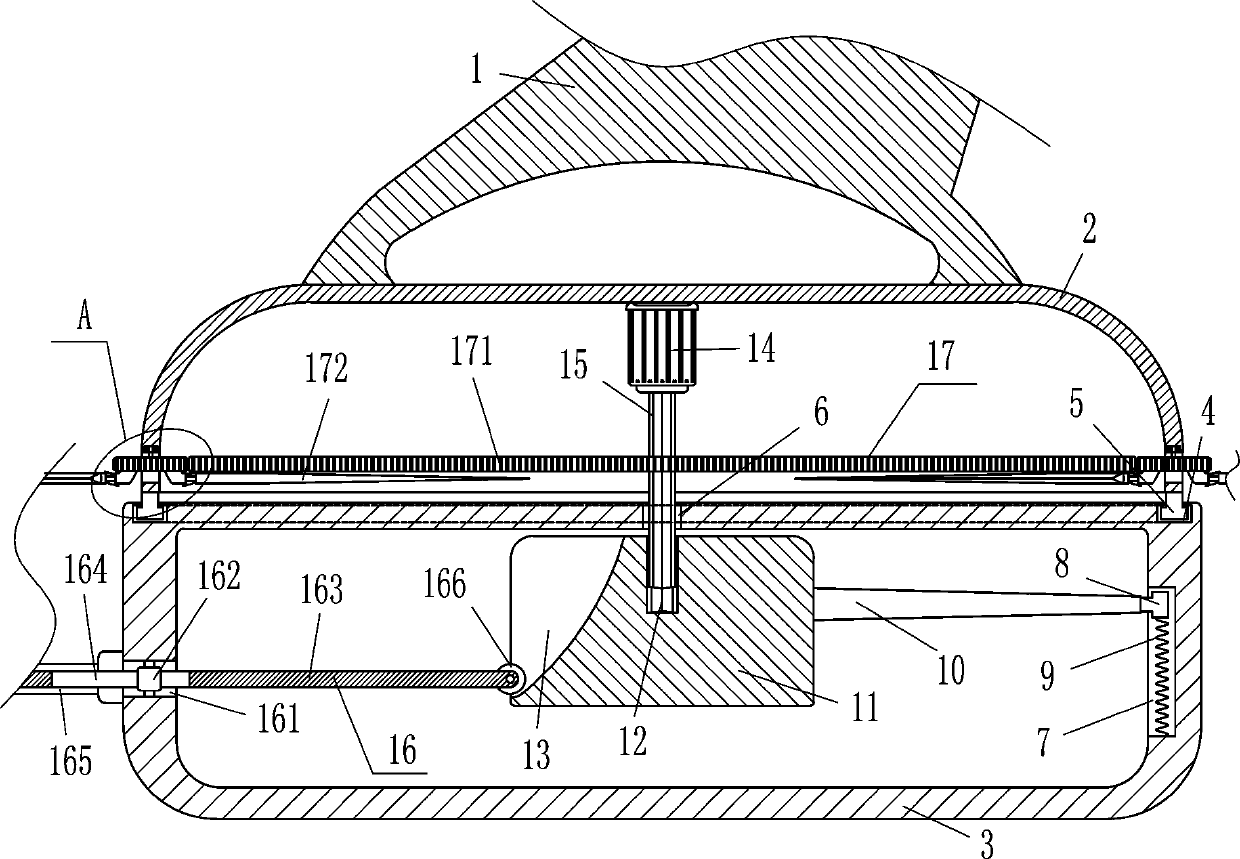

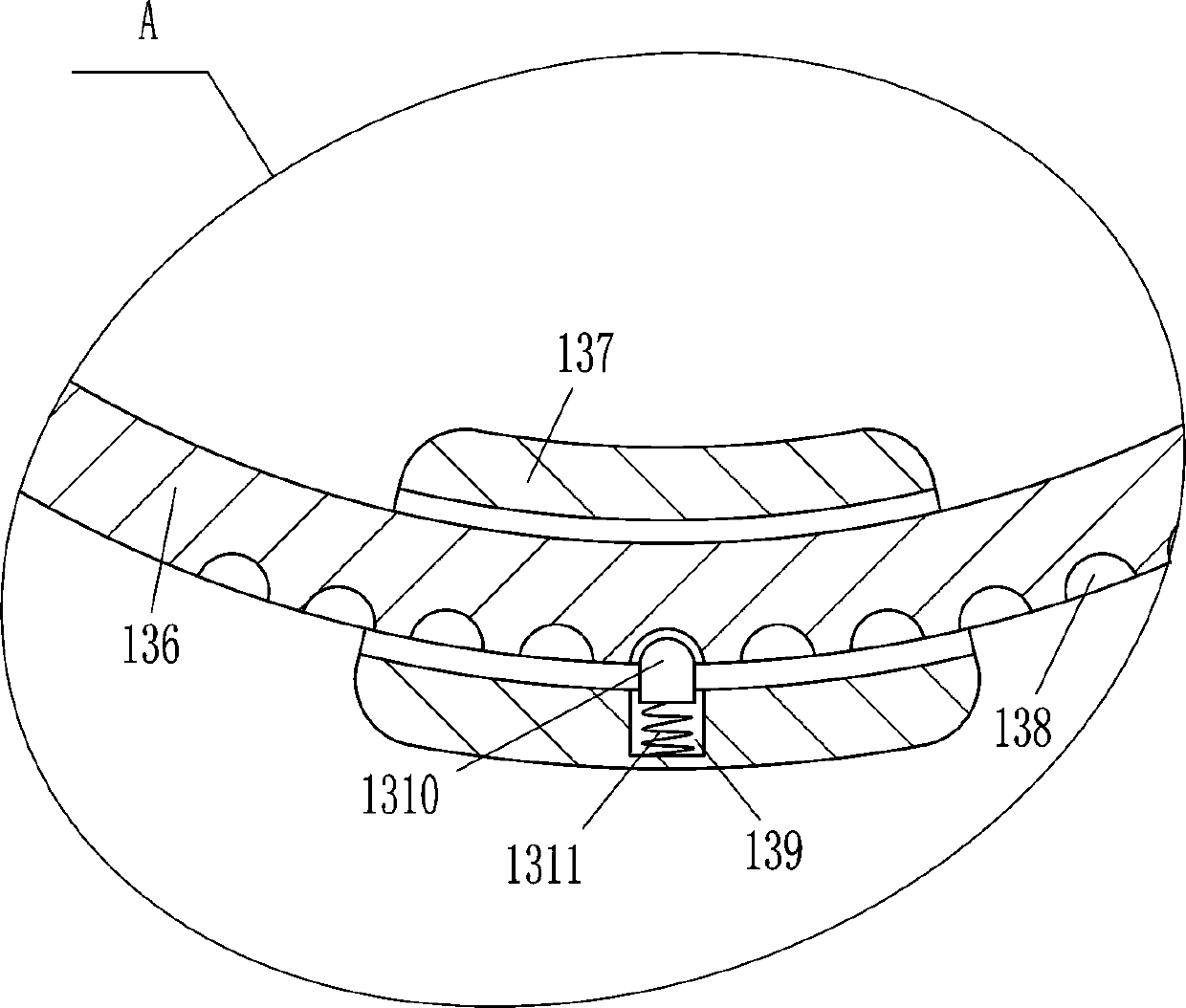

Lawn trimmer preventing cutter breaking

The invention relates to a trimmer, in particular to a lawn trimmer preventing cutter breaking. The technical problem is to provide lawn trimmer which can prevent the cutter from breaking and causingdamage to people, and can cut off residual grass and prevent the residual grass from being stuck to influence the working efficiency. According to the technical scheme: the lawn trimmer comprises a handle, a box cover, a hollow cylinder, an annular sliding block, a vertical sliding block, a first spring and the like; the outer top of the hollow cylinder is circumferentially provided with an annular chute for guiding, two annular sliding blocks matched with the annular chute are arranged in the annular chute, and the box cover is arranged between the tops of the annular sliding blocks at the left side and the right side. According to the invention, through the matching of six-diamond holes and six-diamond rods, when the cutter touches a stone, the annular blocks can move downwards to separate the six-diamond holes from the six-diamond rods, so that the cutter stops rotating forwards, and the cutter can be prevented from rotating continuously when touching the stone, which can cause damage to people.

Owner:林云平

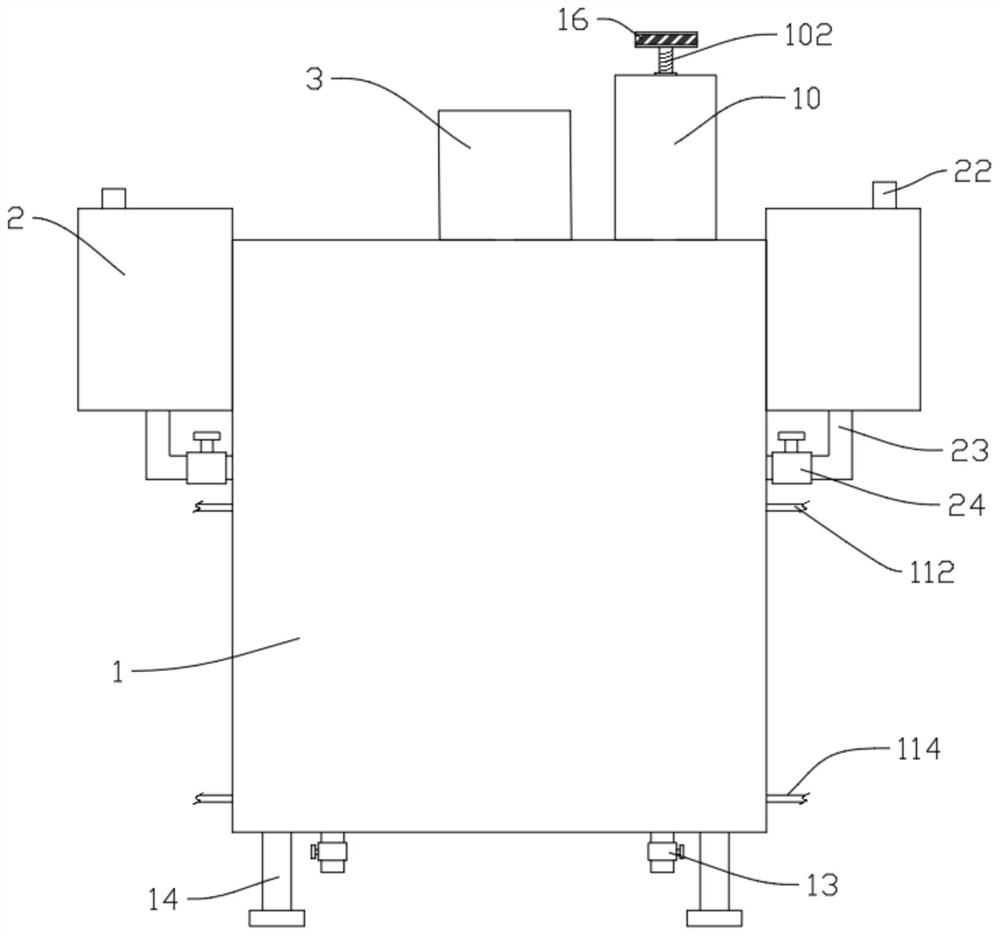

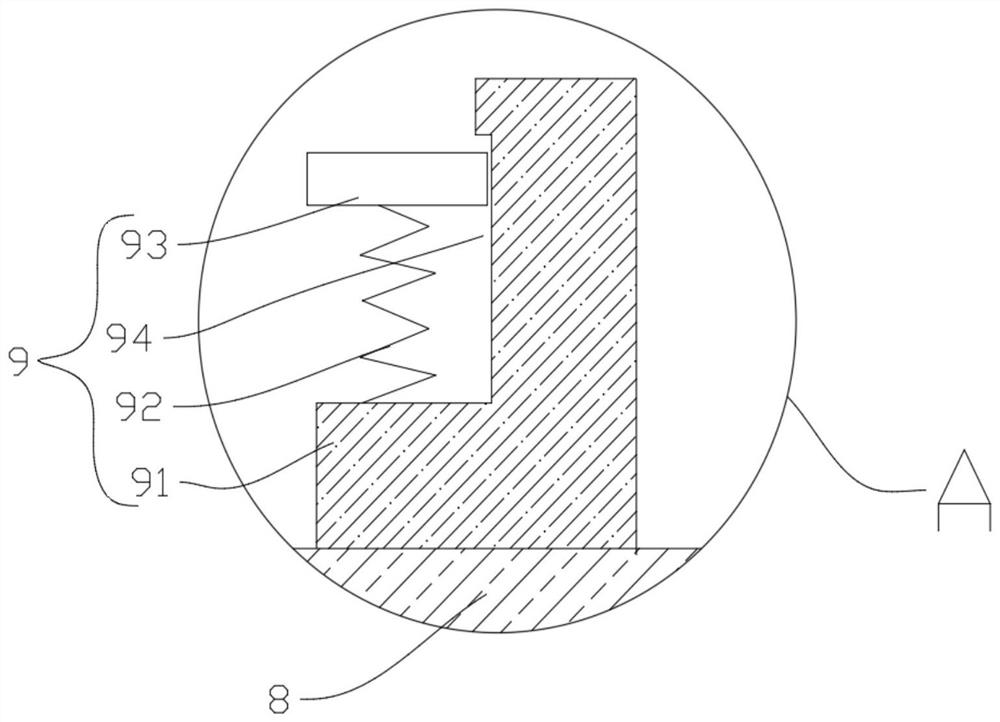

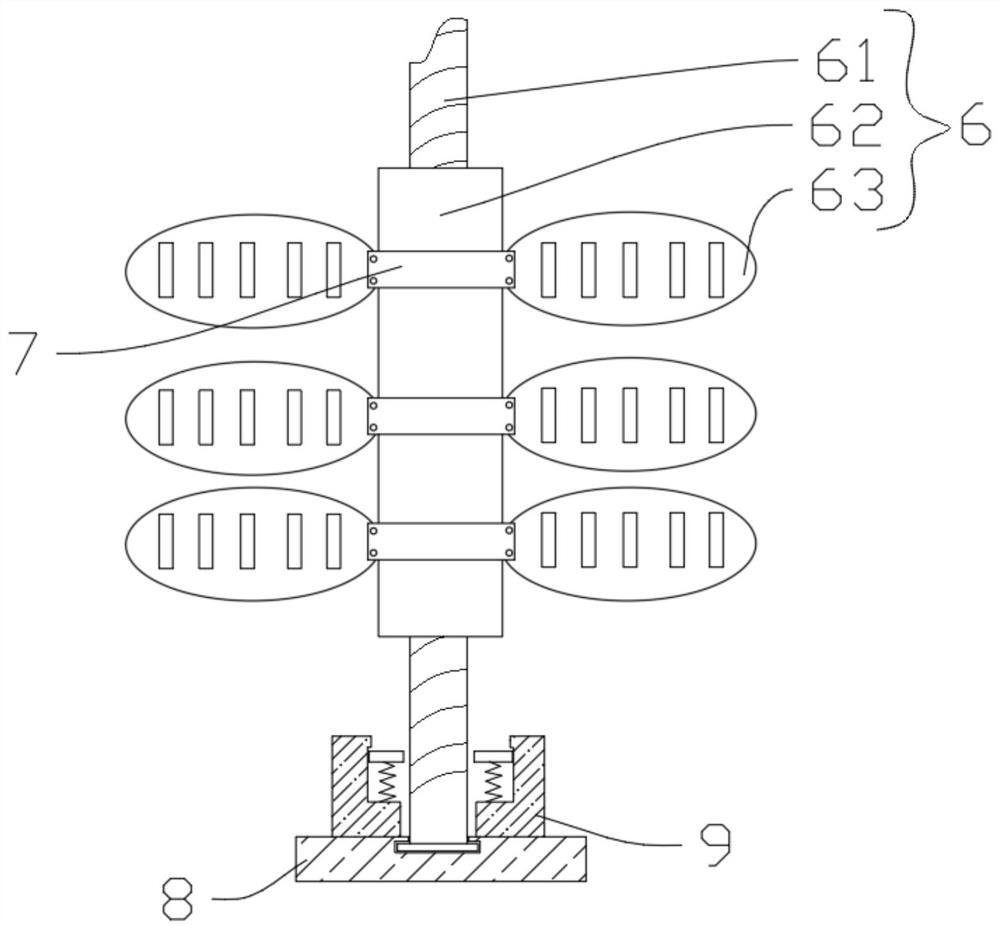

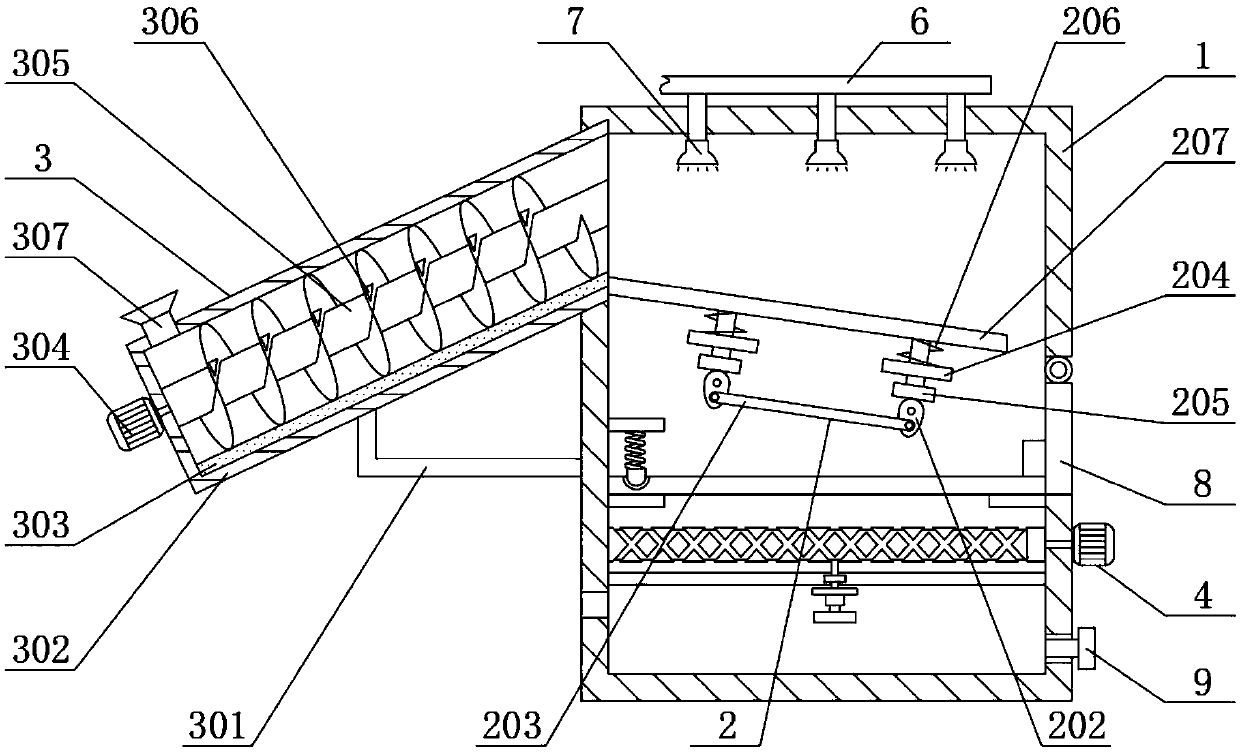

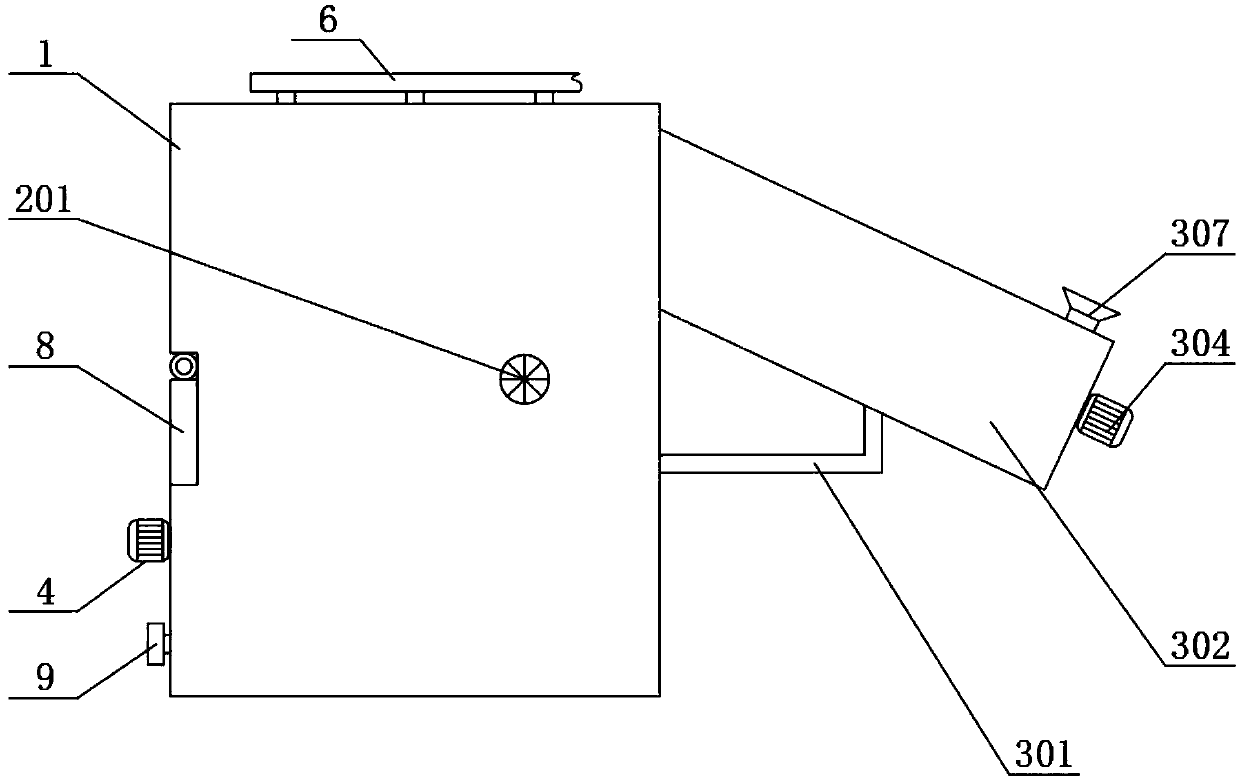

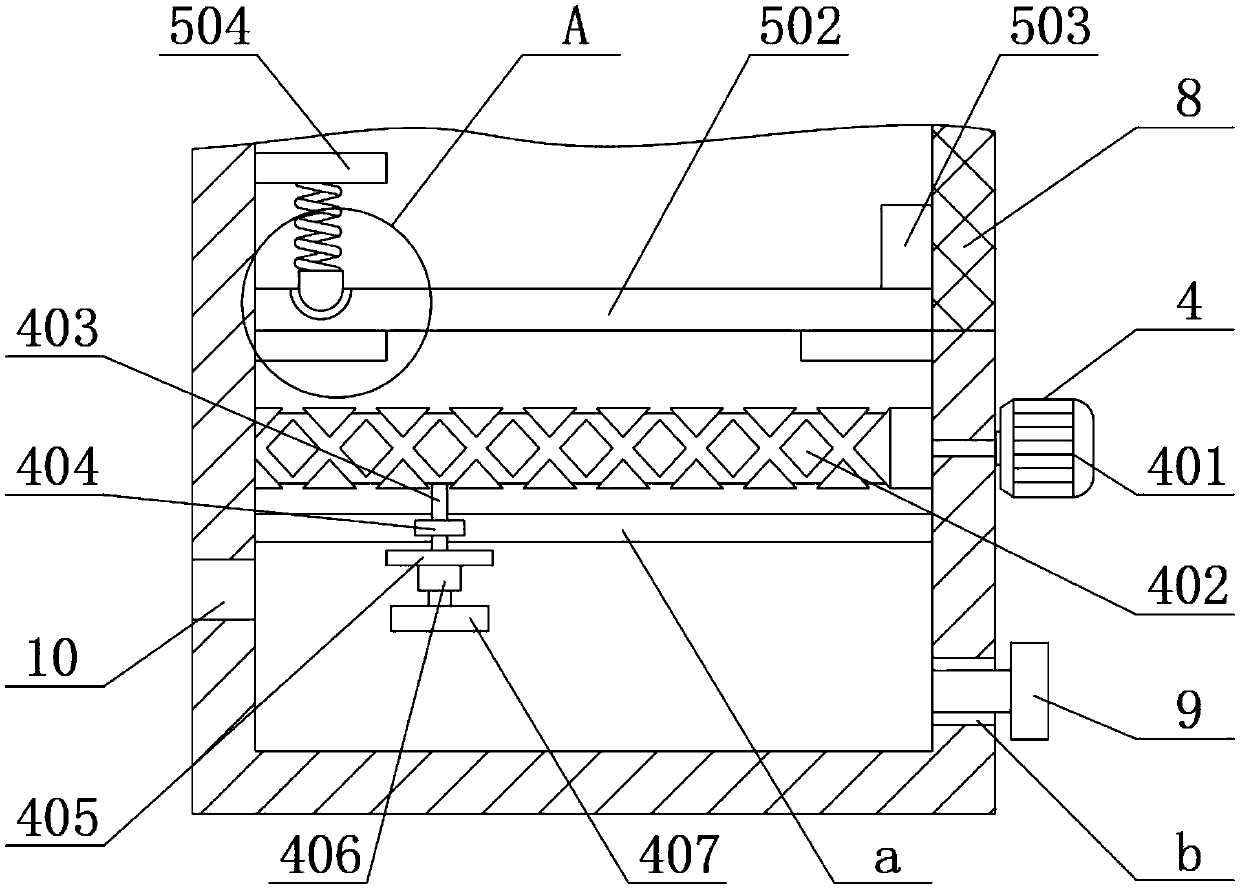

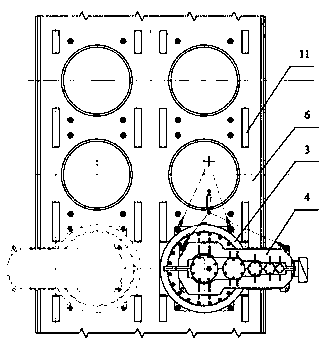

Production equipment for formaldehyde scavenger special for artificial board

InactiveCN112808200AStir wellSolve the problem of excessive production timeProcess control/regulationChemical/physical/physico-chemical stationary reactorsProcess engineeringIndustrial engineering

The invention discloses a production equipment for a formaldehyde scavenger special for artificial boards. The production equipment comprises a reaction box; a feeding mechanism is arranged on the side wall of the reaction box; a motor box is fixedly connected to the top end of the reaction box; a motor is arranged in the motor box; a fixing plate is fixedly connected to the interior of the reaction box; a stirring mechanism is arranged in the reaction box; the output end of the motor penetrates through the side wall of the reaction box to be connected with the stirring mechanism; a fixing base is fixedly connected to the bottom of the inner wall of the reaction box; the fixing plate and the fixing base are each provided with a speed reducing mechanism used in cooperation with the stirring mechanism; a heating mechanism is arranged in the side wall of the reaction box; a discharging pipe is arranged at the bottom of the reaction box; and a discharging valve matched with the discharging pipe is arranged on the discharging pipe. The stirring mechanism is arranged, and a stirring piece can rotate up and down on a reciprocating lead screw in a reciprocating manner, so that a stock solution at the upper part in the reaction box can be stirred, and the problem of overlong production time caused by insufficient stirring is solved.

Owner:CONRIDA FUZHOU ENVIRONMENTAL PROTECTION TECH

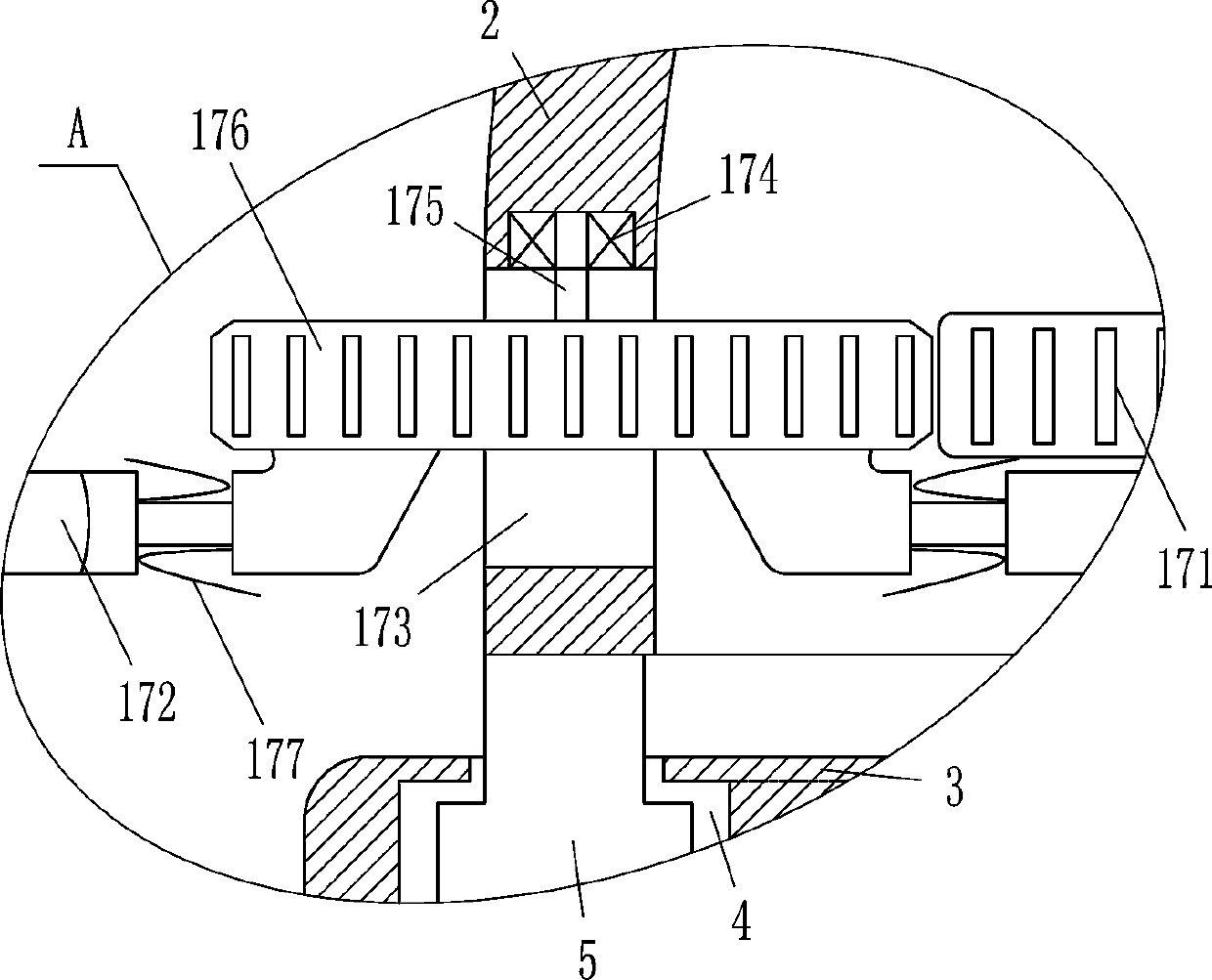

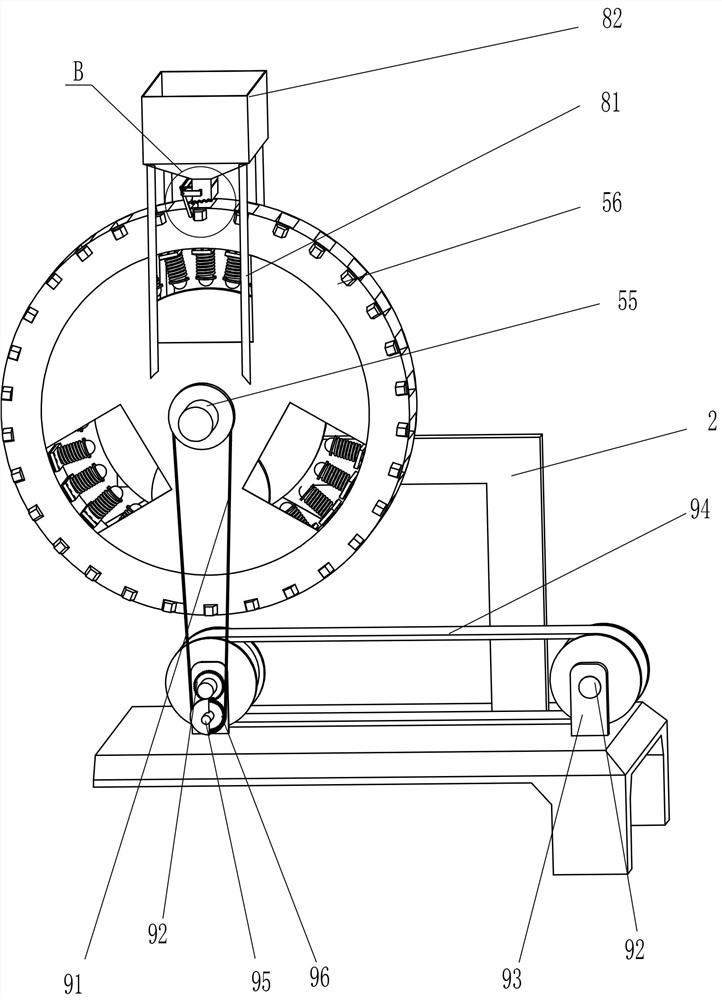

Table-tennis pickup machine

ActiveCN110051995AEasy to take outAvoid affecting follow-up workBall sportsRacket sportsMechanical engineeringWaist

The invention relates to a pickup machine, in particular to a table-tennis pickup machine. The technical aim that the table-tennis pickup machine is capable of replacing manual operation for picking up table tennis, avoiding waist aching pain to influence following work and picking up multiple pieces of table tennis one time and is high in working efficiency. The table-tennis pickup machine comprises a n-type frame, wheels, a movable rod, a frame, a first spring, a pushing handle, first guiding sleeves, guiding rods, second springs, a movable frame, an elastic belt and the like; the wheels arerotationally connected to the bottom ends of the left side and the right side of the n-type frame, and a first through hole with a guiding effect is formed in the left side of the top of the n-type frame. According to the table-tennis pickup machine, a pulling rod is pulled, the elastic belt can move downwards, multiple pieces of table tennis are squeezed into the movable frame, and fall into a collecting frame, persons do not need to continuously stoop to pick up table tennis with the hands, aching pains of the waist are avoided to influence follow-up work, and the working efficiency is alsohigh; through a shifting device, it can be avoided that table tennis in the movable frame is clamped and cannot fall into the collecting frame.

Owner:嘉兴市迅程信息技术有限公司

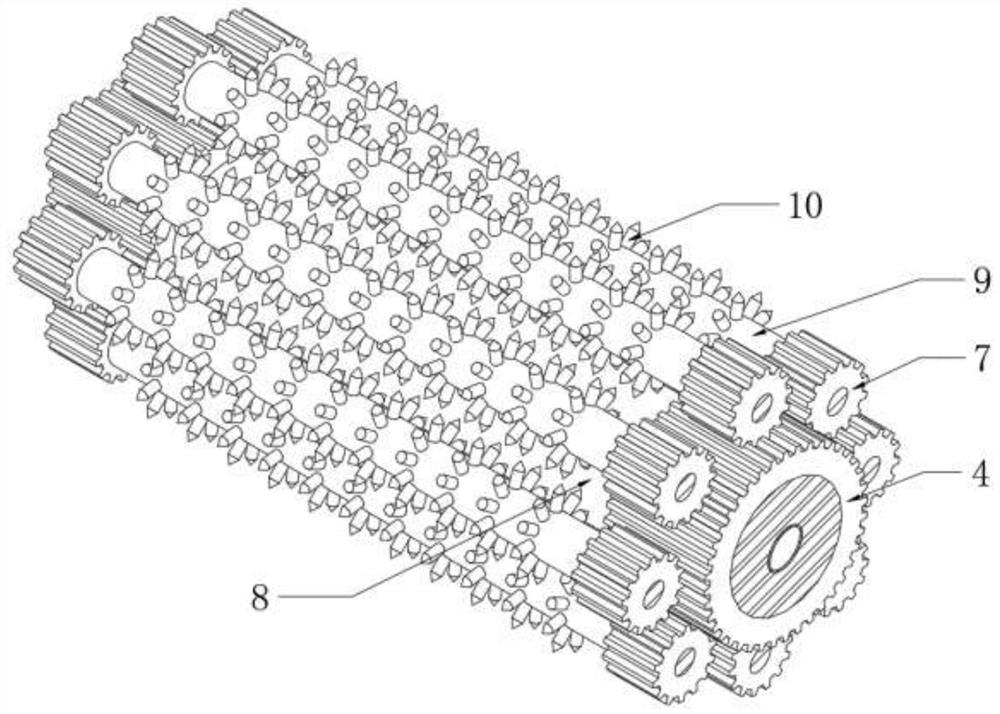

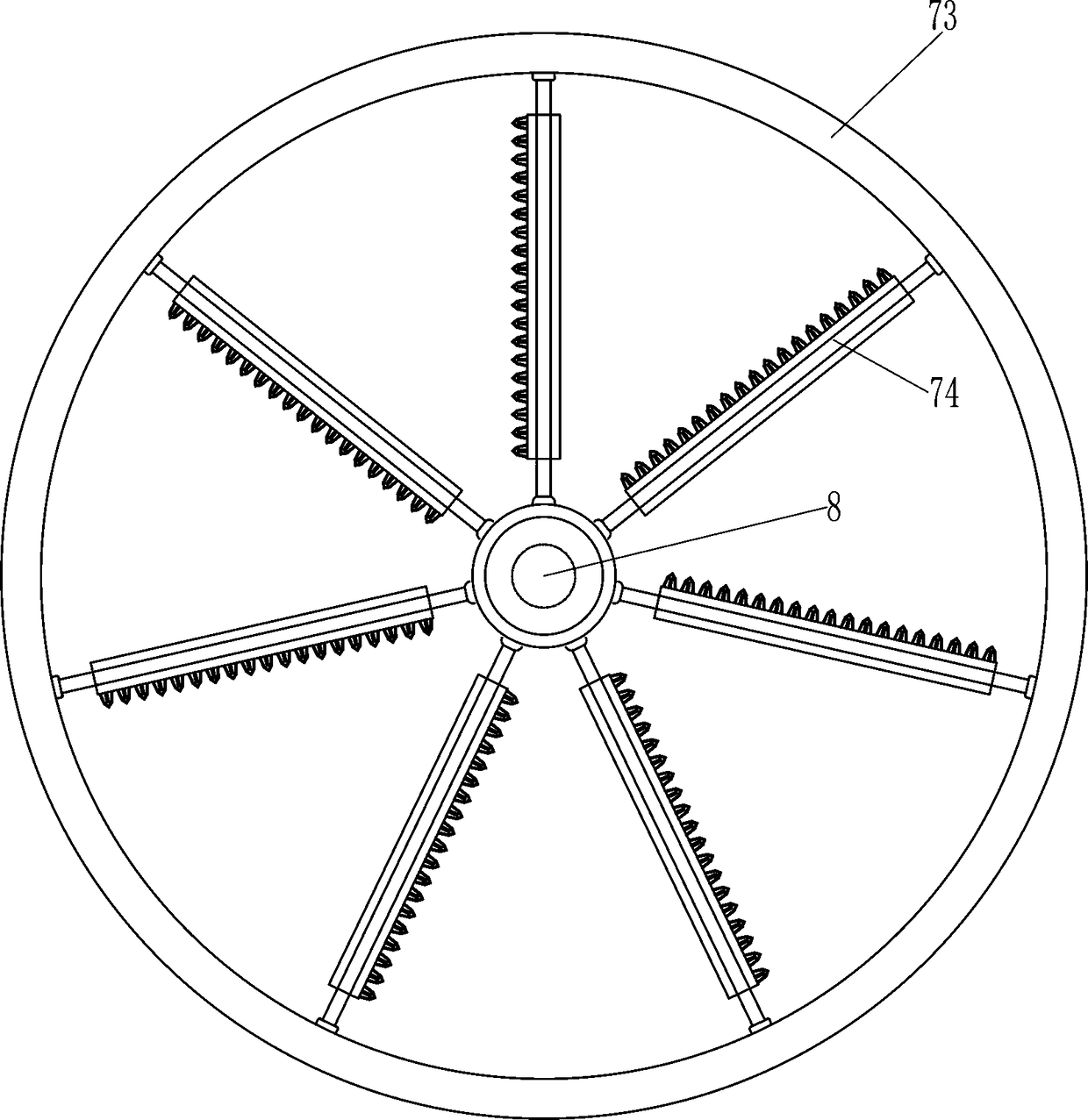

Asphalt pavement milling device

InactiveCN112726357AAvoid affecting follow-up workFull milling treatmentUsing liquid separation agentRoads maintainenceKnife bladesEnvironmental geology

The invention is applicable to the technical field of engineering machinery, and provides an asphalt pavement milling device which comprises a shell, sweeping plates and a collecting plate, a milling assembly is arranged in the shell, the milling assembly comprises a mandrel mechanism and a blade mechanism, a sweeping wheel is rotatably connected in the shell, the multiple sweeping plates are arranged on the periphery of a shaft body of the sweeping wheel at equal included angles, a collecting box is installed in the machine shell, the sweeping plates shovel up waste materials and throw the waste materials into the collecting box after the sweeping wheel rotates intermittently, and therefore milling waste materials are collected and treated, and the situation that the milled waste materials are stacked on the road surface, and follow-up work is affected is avoided, the blade mechanisms and the milling cutter blades enable the asphalt pavement to be fully milled, the milling cutter blades can be replaced after the threads are detached, and therefore the service life of the device is prolonged, the atomization nozzles spray clear water, dust settles after encountering water, and the problem of environmental pollution caused by flying of excessive dust is effectively avoided.

Owner:黄宇

Hardware machining copper and iron fragment separator

ActiveCN110124859AEasy to collect and processAvoid affecting follow-up workMagnetic separationCopperMaterials science

The invention relates to a separator and in particular to a hardware machining copper and iron fragment separator. The technical problem is to provide a hardware machining copper and iron fragment separator that can separate copper fragments from iron fragments instead of a worker, prevents the fatigue of the worker from affecting the subsequent work, and can conveniently collect iron fragments. The hardware machining copper and iron fragment separator comprises a box body, legs, a first bearing seat, a first rotating shaft, a u-shaped rod, an electromagnet and the like. The legs are fixedly connected to the lower parts of the left and the right sides of the box body; the box body has an open bottom; and the first bearing seat is embedded in the upper part of the right side of the box body. The copper and iron fragments are poured into a frame body and are dropped into a material tube to come into contact with a movable plate, and then by rocking a rocking rod, the movable plate can drop the copper and iron fragments into the box body to separate copper from iron by an electromagnet. The hardware machining copper and iron fragment separator avoids attracting the iron fragments witha magnet held by a hand, saves time and effort, and avoids fatigue of the workers from affecting the subsequent work.

Owner:泰州市津专知识产权服务有限公司

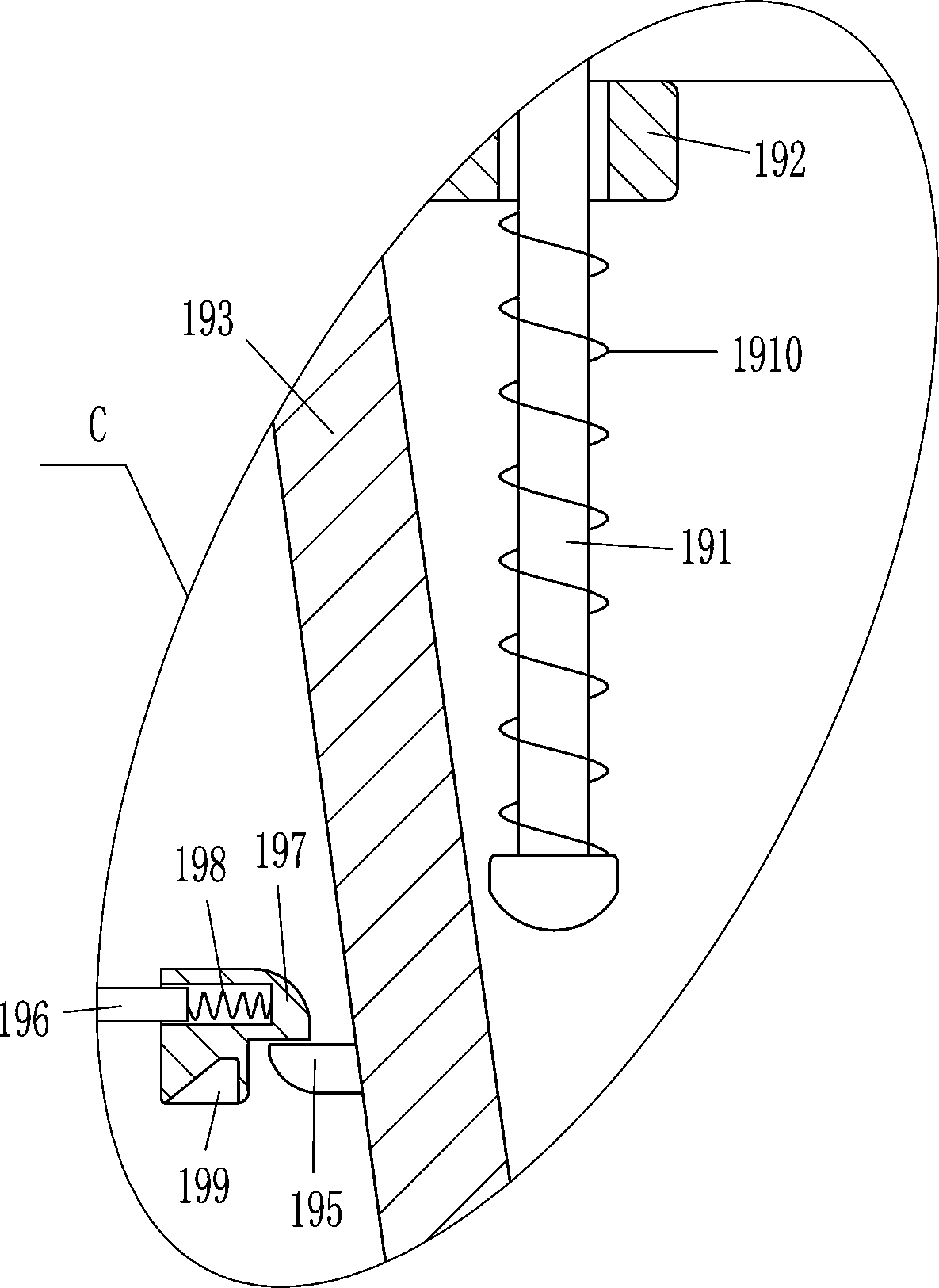

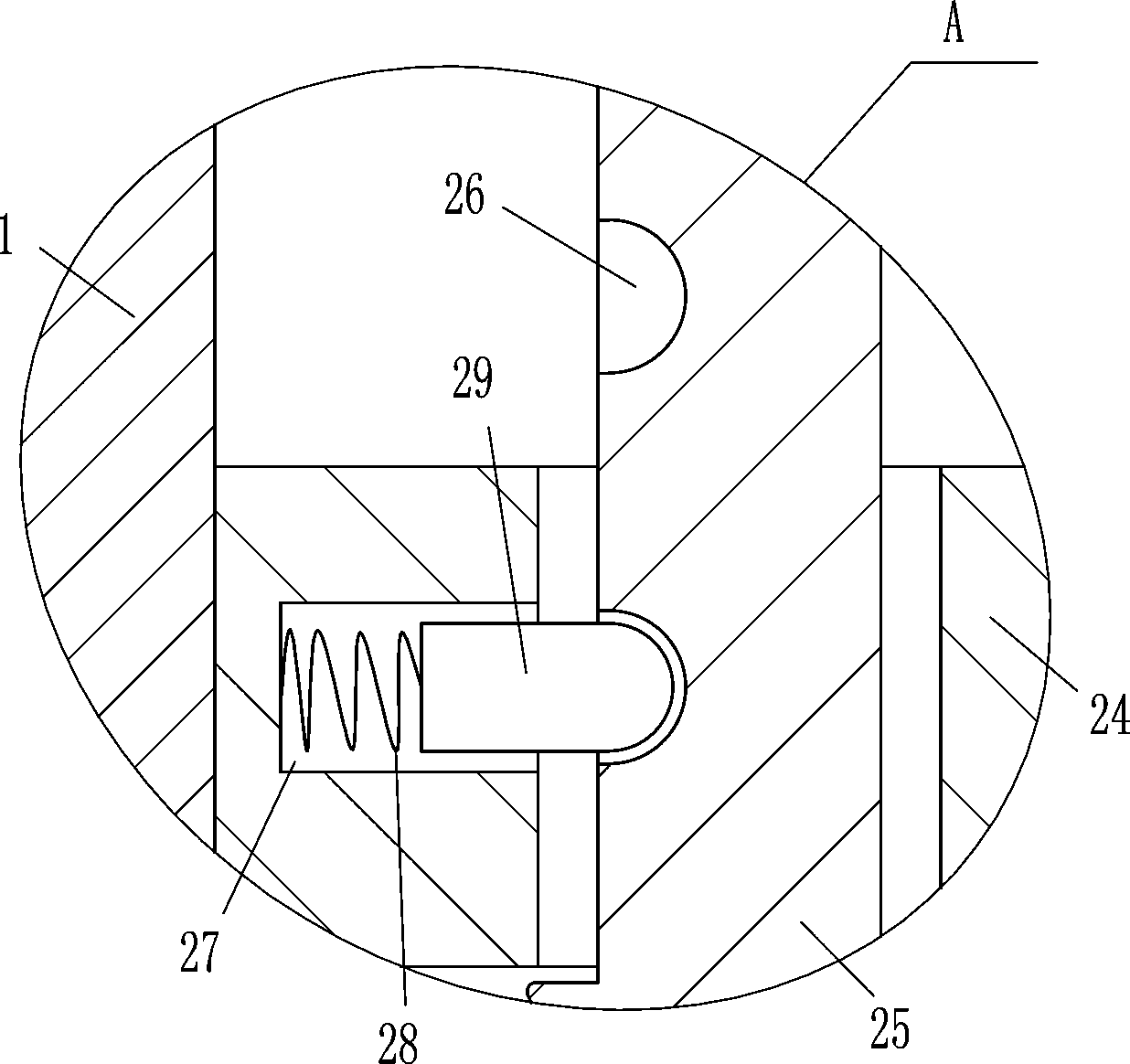

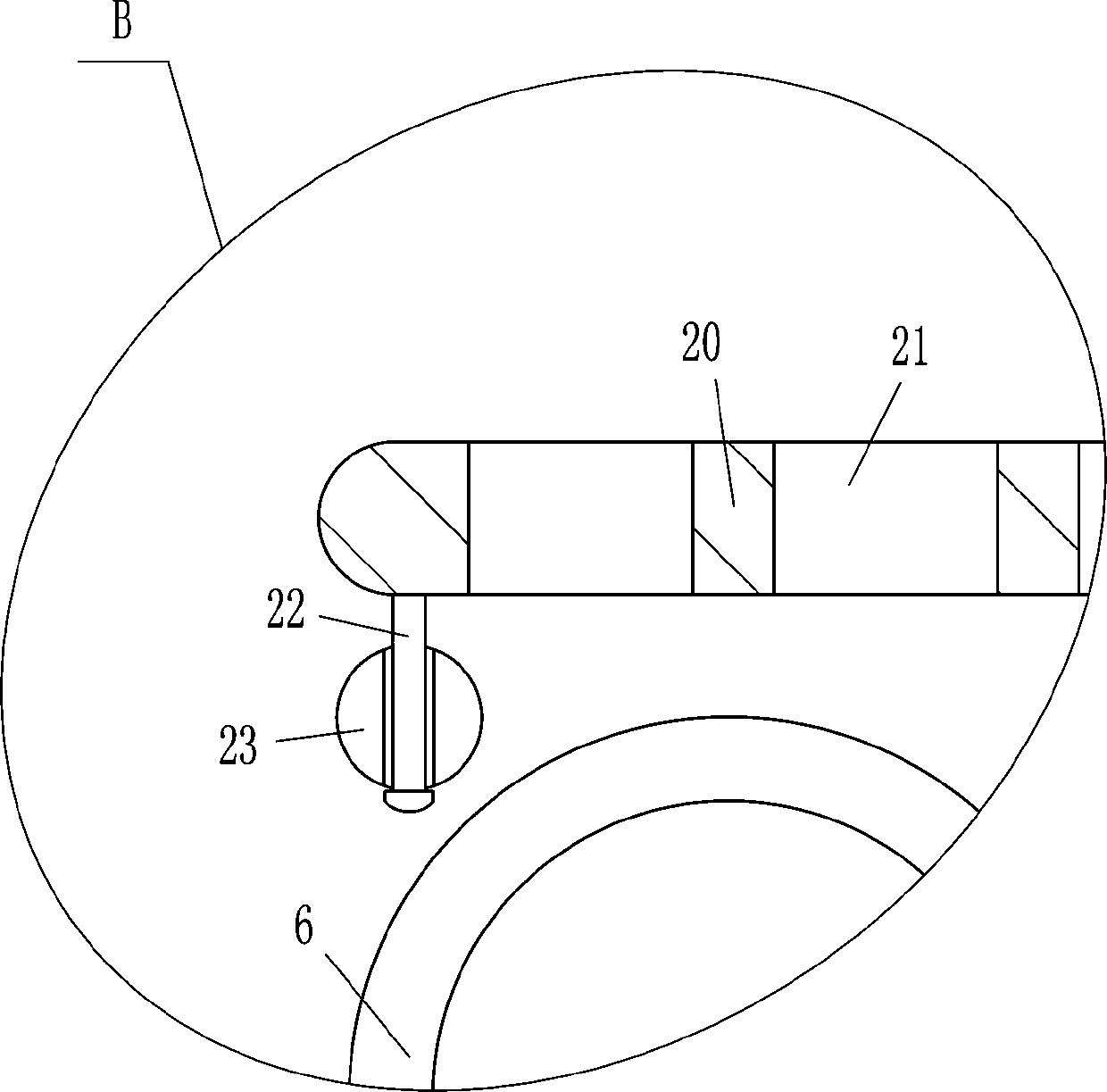

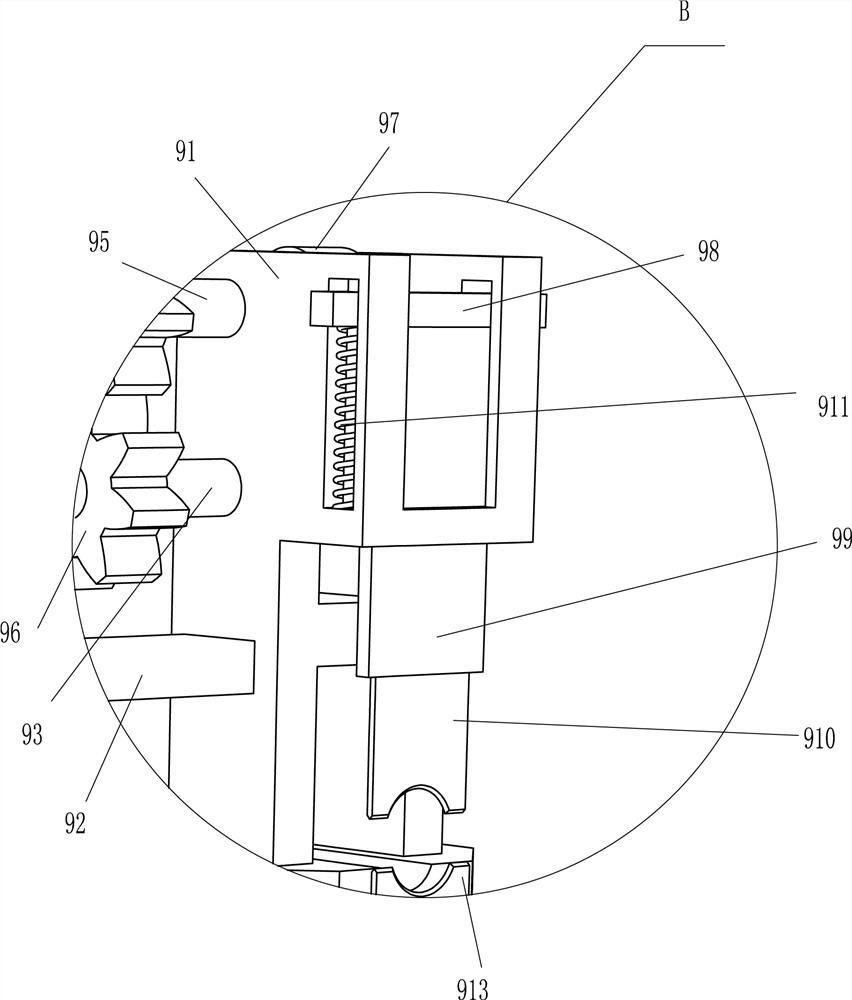

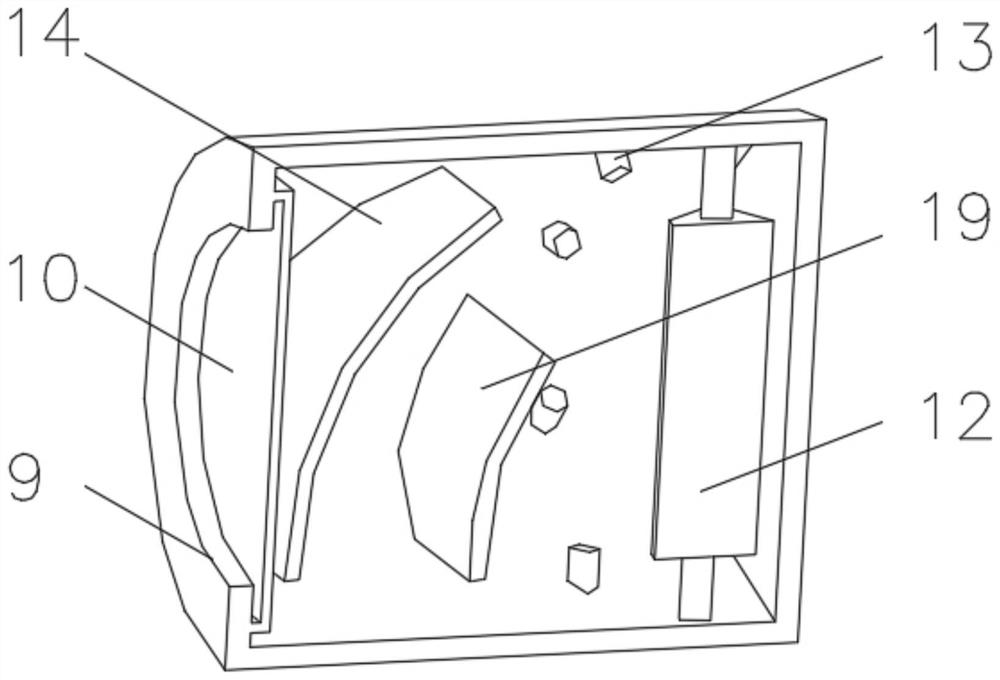

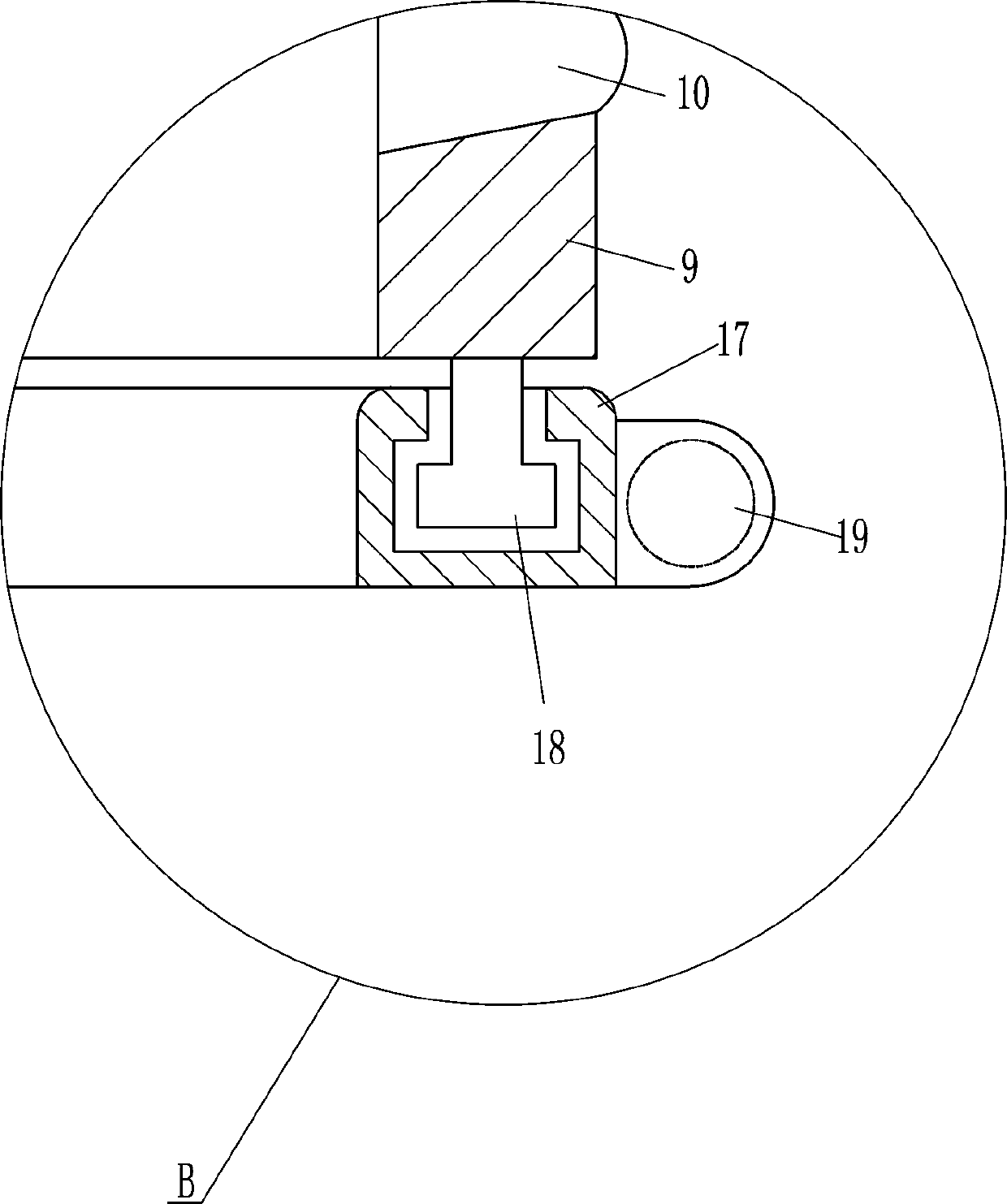

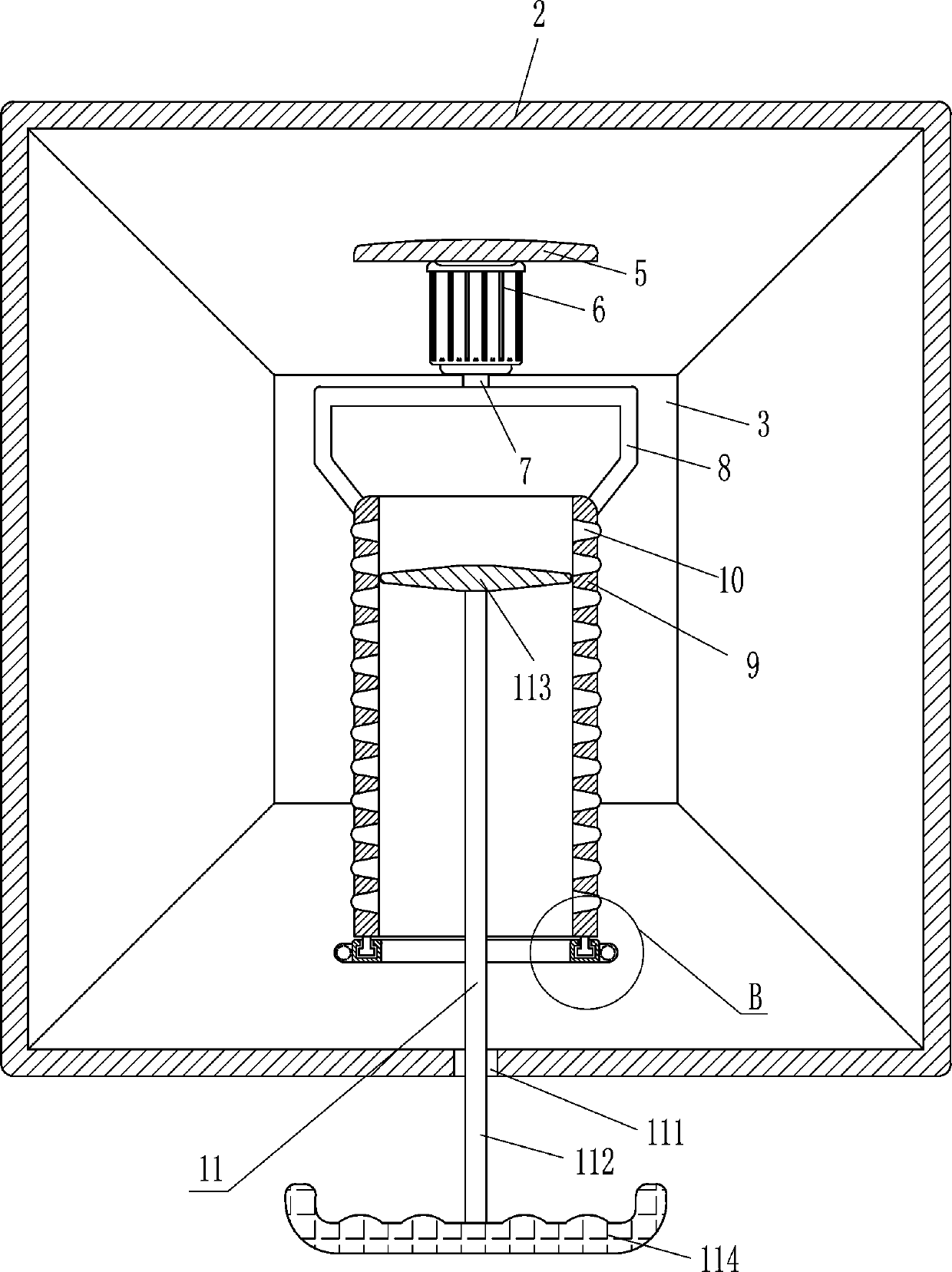

Special tool for salvaging downhole restriction choke by means of logging cable and operation method

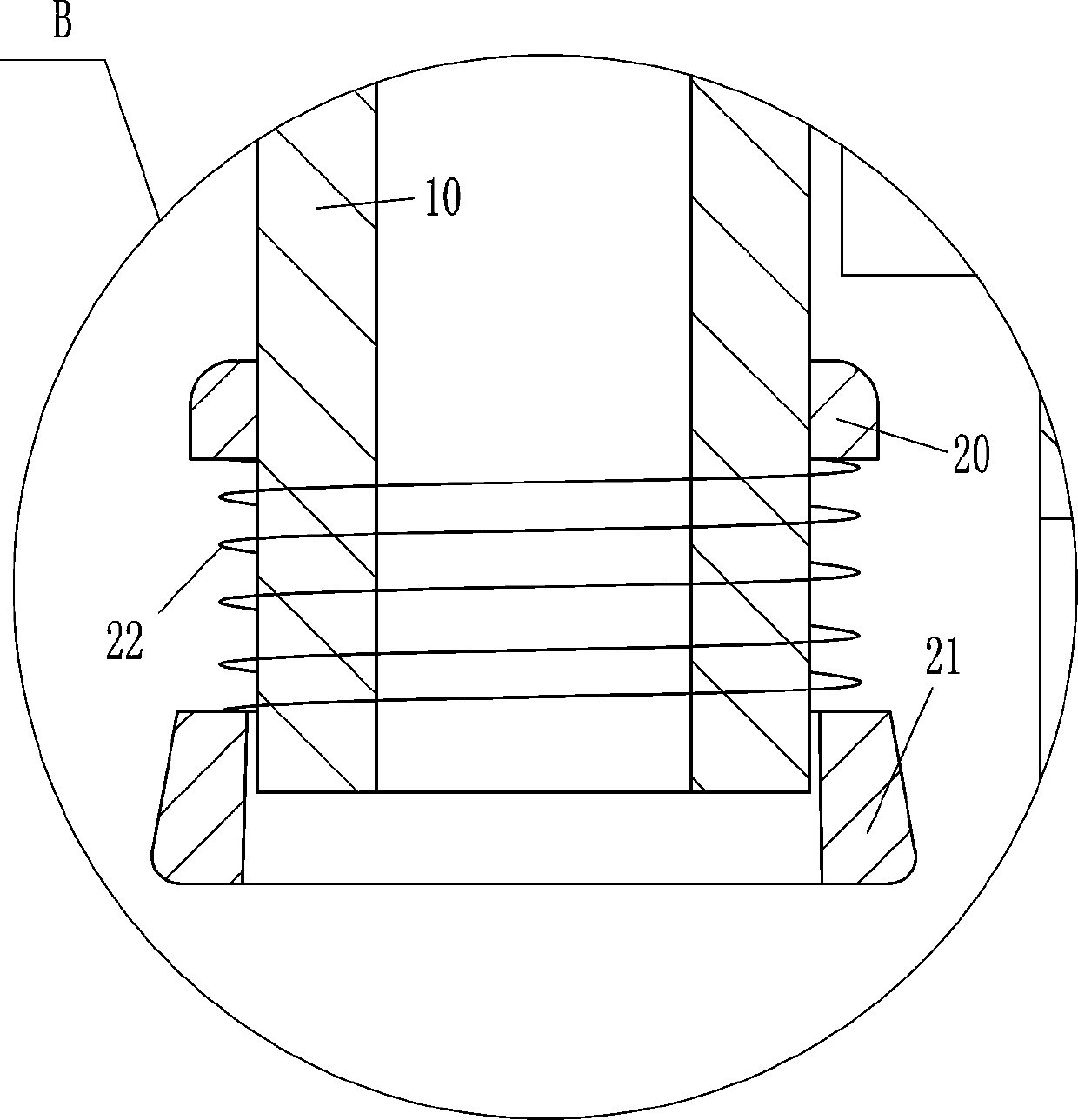

PendingCN107724986ASimple structureIncrease success rateBorehole/well accessoriesPneumatic pressureEngineering

The invention provides a special tool for salvaging a downhole restriction choke by means of a logging cable and an operation method. A salvaging mechanism and a pneumatic pressing mechanism are integrated; a separation ring is arranged between a mandrel and a supporting pipe, and a locking sleeve and the mandrel are fixed through a shear pin; a gap is reserved between the supporting pipe and a connection block; when a salvaging tool is lowered down, and when a clamping claw is in contact with a salvaging neck of the restriction choke, the clamping claw moves upwards under an upward thrust ofthe restriction choke; damage to the tool due to extremely high impact force can be avoided by buffering of a rectangular spring; the clamping claw and the connection block can move upwards together;when the connection block touches the separation ring, the movement is stopped; at the moment, the clamping claw clamps the salvaging neck of the restriction choke under the upward thrust to completeclamping operation; and the special tool is simple in structure and relatively high in success rate.

Owner:PETROCHINA CO LTD

Oil sunflower floral leaf wring-dropping apparatus

The invention relates to a wring-dropping apparatus, and especially relates to an oil sunflower floral leaf wring-dropping apparatus. The purpose of the invention is to provide the oil sunflower leafwring-dropping apparatus capable of mechanically wring-dropping floral leaves and avoiding sunflower seeds from being scraped off. The oil sunflower floral leaf wring-dropping apparatus comprises a base, a first supporting rod, a frame body, a limiting rod, a first telescopic rod, a push rod, a wring-dropping device, a rotating shaft, a rotating wheel, mounting blocks, connecting rods, scraping balls and the like; and the left part of the upper side of the base is connected with the first supporting rod, the upper part of the first supporting rod is rotatably connected with the frame body, theright part of the lower side of the frame body is connected with the limiting rod, the right part of the upper side of the base is connected with the first telescopic rod, and the front side of the upper part of the first telescopic rod is connected with the push rod. The rotating wheel is rotated to drive the wring-dropping device to rotate through the rotating shaft in order to wring-drop the floral leaves, so the apparatus is convenient for people to use; and the apparatus is provided with arc-shaped heating wires, the arc-shaped heating wires can generate heat to dry the closely-sticky floral leaves to a certain degree.

Owner:刘永康

Fast-assembled steel structure building main body

ActiveCN112177158AInsert deepInsertion installation depthElectric spark ignitersBuilding material handlingArchitectural engineeringPipe

The invention relates to a fast-assembled steel structure building main body which comprises a concrete base, a mounting piece, a steel structure building wallboard, fixed sleeves, a triggering deviceand a reinforcing device. The mounting piece extends in the front-back direction and is mounted on the upper surface of the concrete base. The steel structure building wallboard is vertically arranged and extends in the front-back direction, inserting rods extending downwards are arranged on the bottom end face of the steel structure building wallboard, and spiral grooves are formed in the peripheral walls of the inserting rods. The fixed sleeves comprise sleeve bodies, inserting rod grooves, impact channels and igniter grooves. The impact channels are arranged in the sleeve bodies and comprise reaction cavities, conveying pipes and acting cavities. The triggering device comprises igniters, a ground wire and reaction substance blocks. The reaction substance blocks are arranged in the reaction cavities. The igniters are connected with the reaction substance blocks through the ground wire. The reinforcing device comprises an impact sleeve, steel nails and an explosive. The steel nails can be inserted into the inserting rods through the reinforcing device, and reinforcing is achieved. The structure of the fast-assembled steel structure building main body is stable, and fast mountingcan be achieved on the steel structure building wallboard.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

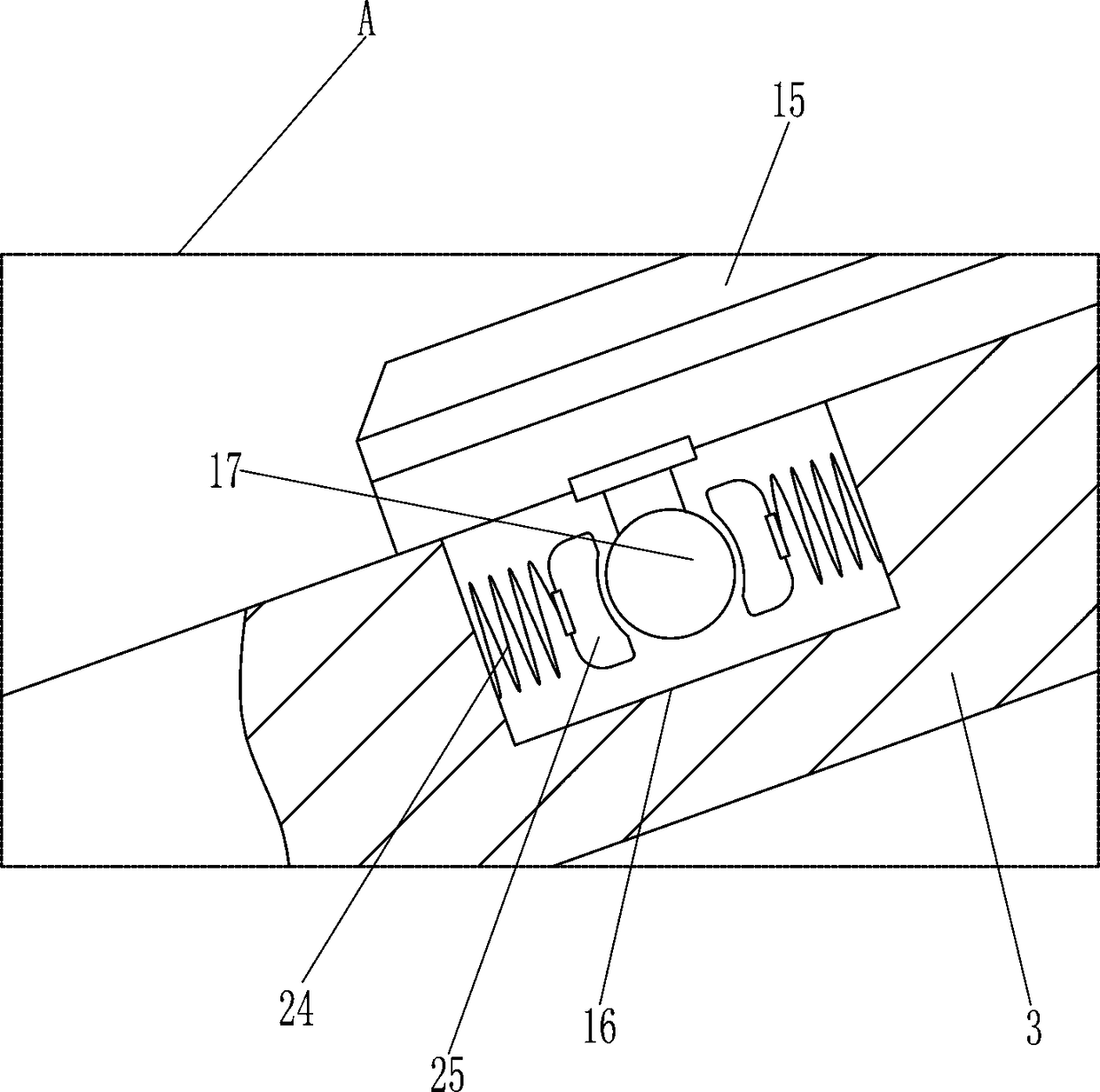

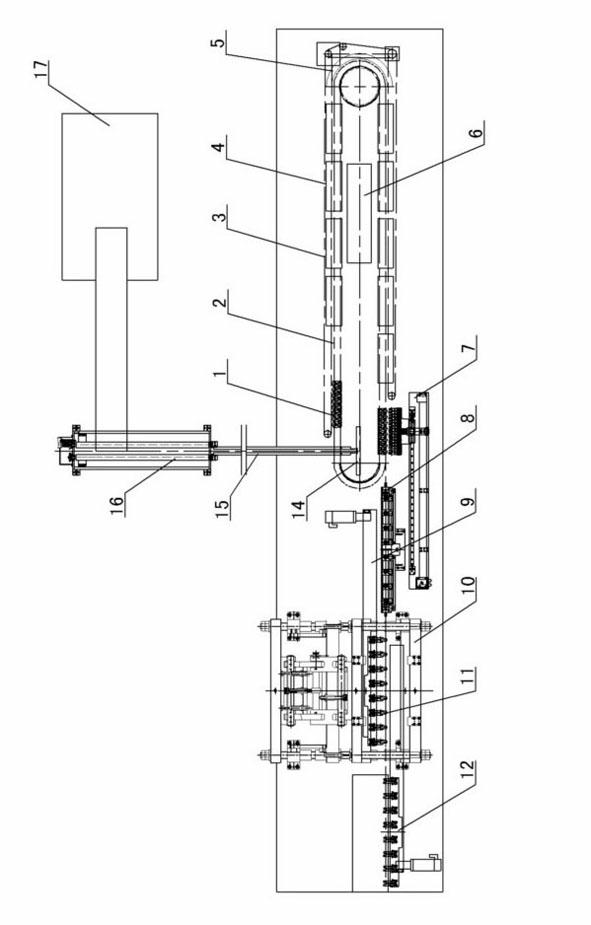

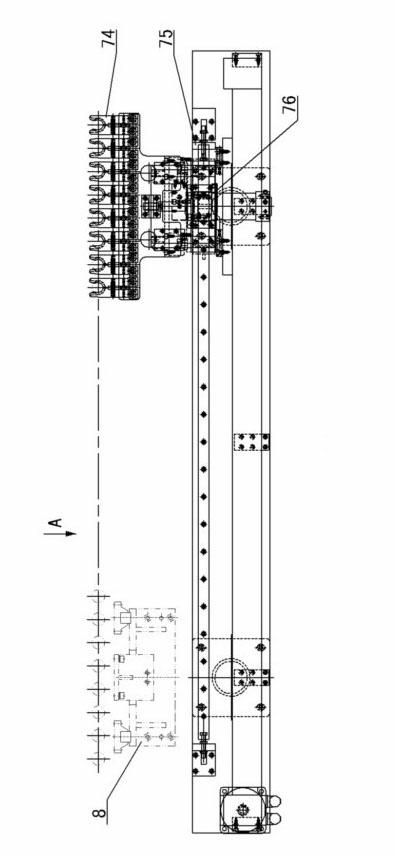

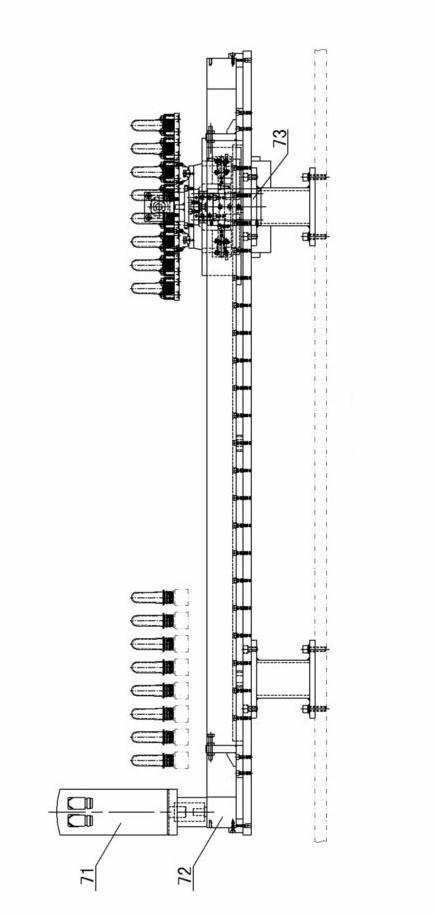

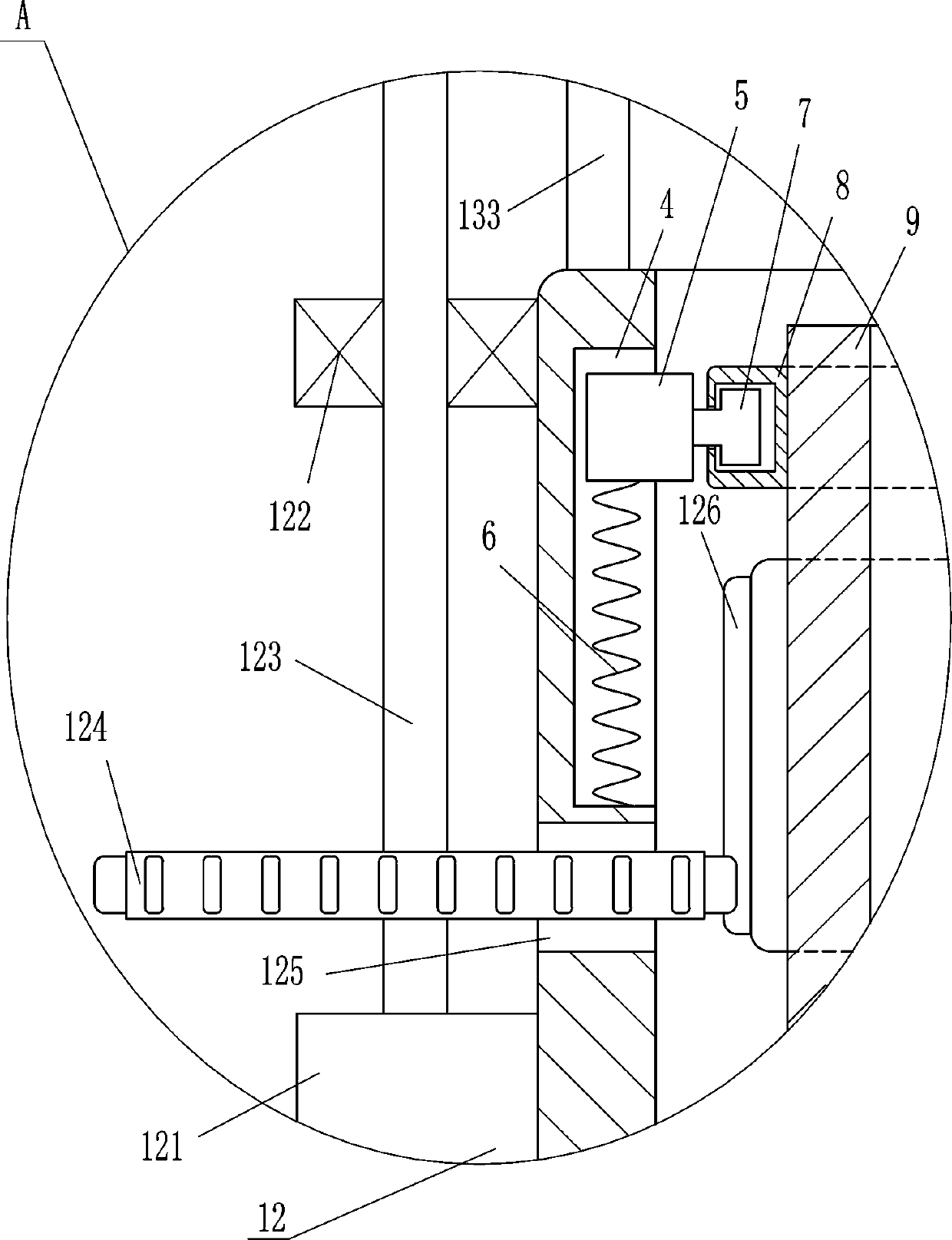

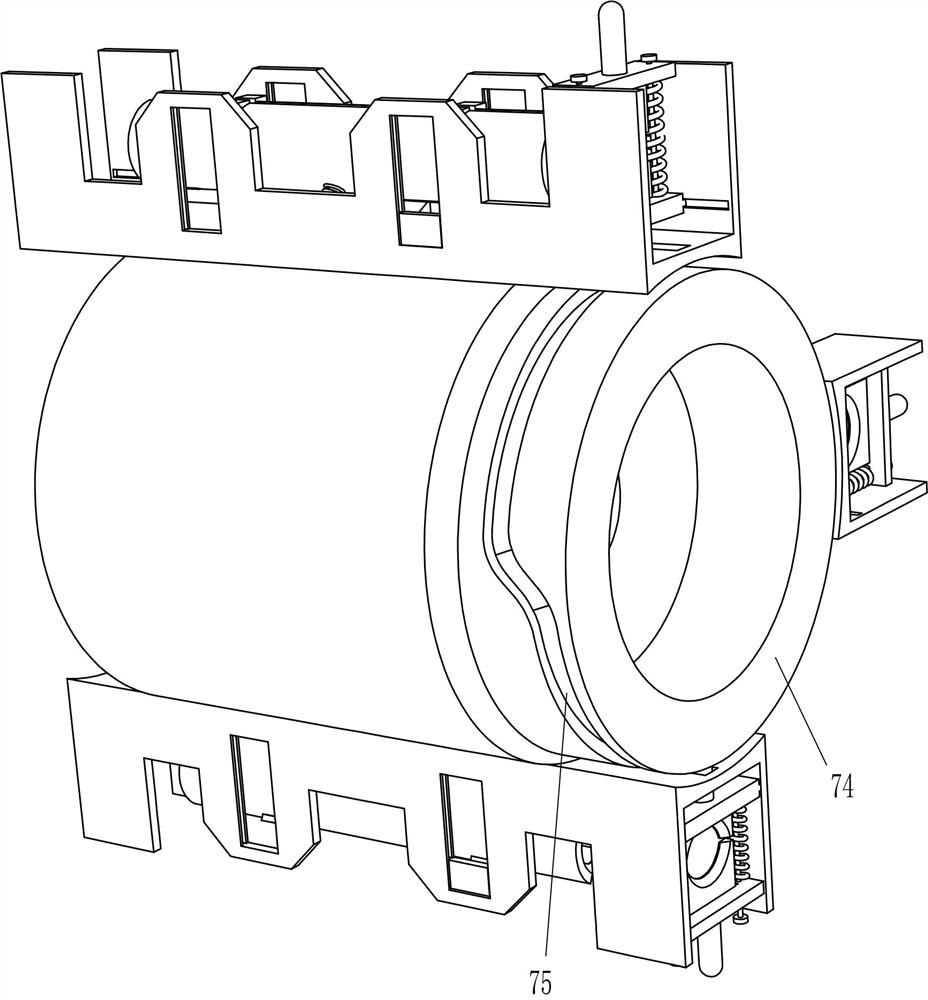

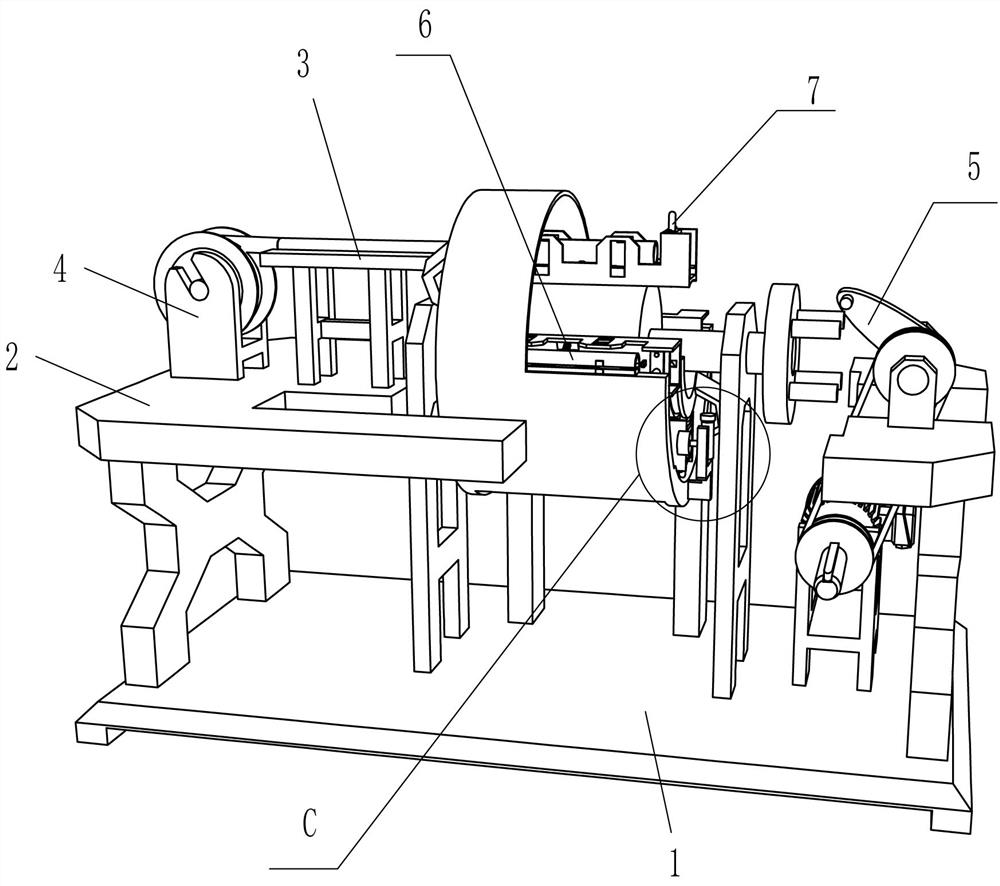

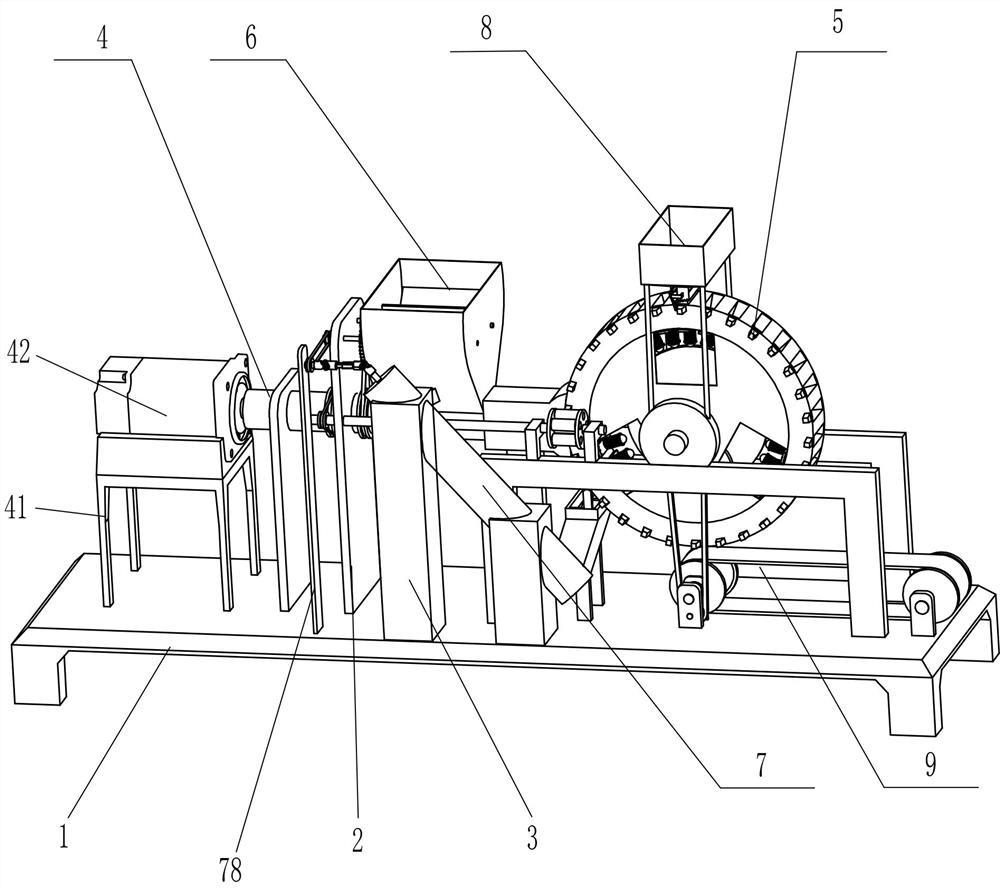

Rotary blank-feeding linear automatic bottle blowing machine

The invention discloses a rotary blank-feeding linear automatic bottle blowing machine, which comprises a heater and a pull blowing machine, wherein the heater is provided with a blank-feeding mechanism; the blank-feeding mechanism is provided with a blank introducing frame, a single slipway discharger and a conveyer; a blank taking mechanism, a relay station and a blank conveying mechanism are arranged between the heater and the pull blowing machine; the heater comprises a follower fixture, a revolution transmission, an autorotation transmission, a heating lamp box, a conveying guide rail and an air extracting device; and the pull blowing machine comprises a die closing mechanism, a seal stretcher and a bottle taking mechanism. The bottle blowing machine is characterized in that: the blank taking mechanism comprises a servo motor, a blank taking electric cylinder, a lifting cylinder, a blank taking manipulator, a blank taking linear guide rail and an advancing and retreating cylinder; the relay station comprises a strut head, a chain, a switching cylinder, an upgrade cylinder and a relay station linear guide rail; and the seal stretcher comprises a seal support seat, a sliding seat, a pedestal, a synchronous belt, a stretching rod, sliding angle iron, a synchronous belt pulley, a seal motor, a seal lifting cylinder and a seal linear guide rail.

Owner:王自强

Sesame screening device

ActiveCN110142150AAvoid falling outAvoid affecting follow-up workRotary centrifugesSesamum orientaleEngineering

The invention relates to a screening device, in particular to a sesame screening device. According to the technical aims to be achieved, the sesame screening device can replace manpower to screen sesame, and the situation that subsequent work is influenced by hand aches, the sesame is prone to being burst out, and waste is caused is avoided. According to the following technical scheme, the sesamescreening device comprises a base, a box, a discharging pipe, first sliding blocks and the like; and the box is arranged at the top of the base, the discharging pipe is arranged on the lower portion of the left side of the box and communicates with the interior of the box, and upper sliding grooves are formed in the upper portions of the left side and the right side in the box. A screening frame moves up and down while rotating by starting a drive motor, then the screening frame can screen the sesame, people can put a collection frame at the position below the left portion of the discharging pipe to collect the screened-out sesame, the operation that people constantly shake a screen to screen the sesame is not needed, and more labor is saved; and the situation that subsequent work is influenced by hand aches is avoided, and the situation that the sesame is prone to being burst out to cause waste can be avoided by the height of the screening frame.

Owner:临沂恩科开发建设有限公司

Wire sheath removing device for two ends of wire

ActiveCN112531577AEasy to operateAvoid affecting follow-up workApparatus for removing/armouring cablesEngineeringWorkbench

The invention relates to a wire skin removing device and particularly relates to a wire skin removing device for two ends of a wire. The wire skin removing device for the two ends of the electric wirecan remove wire skins at the two ends of the electric wire at a time, and is high in working efficiency, convenient to operate and labor-saving. The wire skin removing device for the two ends of theelectric wire comprises a base, a feeding table and a material frame, wherein a workbench is installed on one side of the base; the feeding table is mounted on the workbench; and the material frame ismounted on the workbench. According to the device, the wire is sleeved on the material rack, a head end of the wire is pulled to move to a proper position in the material clamping device to be limited, the wire is cut off at the proper position by the scissors, the rotating device is started to drive the material clamping device to operate, the material clamping device operates to drive the wirestripping device to operate, and the wire stripping device operates to strip the two ends of the wire; and manual wire skin removal on two ends of the wire is not needed, so operation is convenient and labor-saving.

Owner:湖南诚合鑫科技有限公司

Duck meat cleaning apparatus

ActiveCN109527053APrevent slippingReduce manual feedingPoultry cleaning/disinfectionWater filterEngineering

The invention relates to the technical field of duck meat cleaning, and especially relates to a duck meat cleaning apparatus. The apparatus comprises a box body, a cleaning device is arranged inside the box body, the cleaning device comprises a first motor, the rear end of the box body is fixedly connected with a first motor, eccentric wheels are arranged at the end of the main shaft of the firstmoor and the inner side of the rear end surface of the box body, the front ends of the eccentric wheels are rotatably connected with a connecting rod, the inner side of the rear end surface of the boxbody is fixedly connected fixed plates, the inner side of every fixed plate is slidably connected with a movable rod, one end of every movable rod is fixedly connected with a water filter plate, anda first spring sleeves the outside of every movable rod. The apparatus is provided with the eccentric wheels, the first springs and the water filter plates, the eccentric wheels drive the movable rodsto slide up and down, and block-shaped duck meat is lifted up by the water filter plates under the elastic action of the first springs, so the sticky duck meat is easily separated, and the influenceson the cleaning effect is avoided, thereby the apparatus has a good cleaning effect and a high duck block cleaning efficiency.

Owner:湖南芷江和翔鸭业有限公司

Cement grinding and screening device

InactiveCN112916086AEasily exploitedImprove practicalitySievingScreeningEngineeringStructural engineering

The invention discloses a cement grinding and screening device. The cement grinding and screening device comprises a treatment frame, wherein supporting frames are symmetrically installed at the bottom of the treatment frame, a base is installed at the ends, away from the treatment frame, of the supporting frames, one side of the treatment frame is communicated with a material pushing pipe, and a dustproof cover is installed at the end, away from the treatment frame, of the material pushing pipe; a feeding port is formed in the side, away from the supporting frame, of the treatment frame, a sliding cover is connected to the position, close to the feeding port, of the inner wall of the treatment frame, a handle is installed at one side of the sliding cover, a discharging port is communicated with the side, away from the material pushing pipe, of the treatment frame, and a screen is fixedly connected to the position, close to the discharging port, of the inner wall of the treatment frame; and a hole cleaning device is mounted at the position, close to the treatment frame, of the inner wall of the treatment frame. According to the cement grinding and screening device, the purpose of effectively crushing large particles of cement raw materials is achieved, and it is guaranteed that the sizes of the particles of the cement raw materials are small, so that the particles are easier to use.

Owner:李秀群

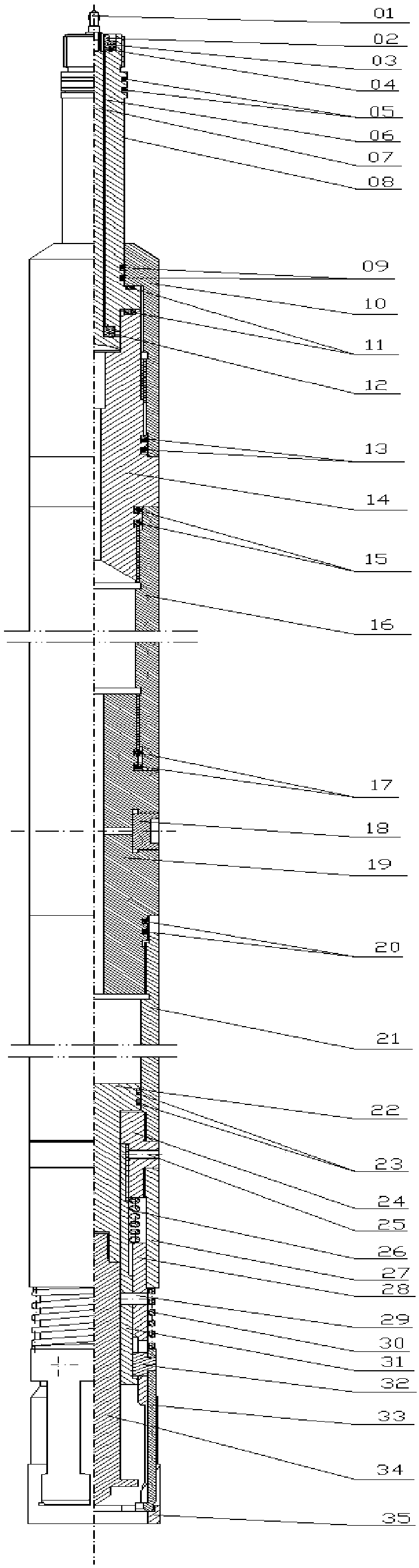

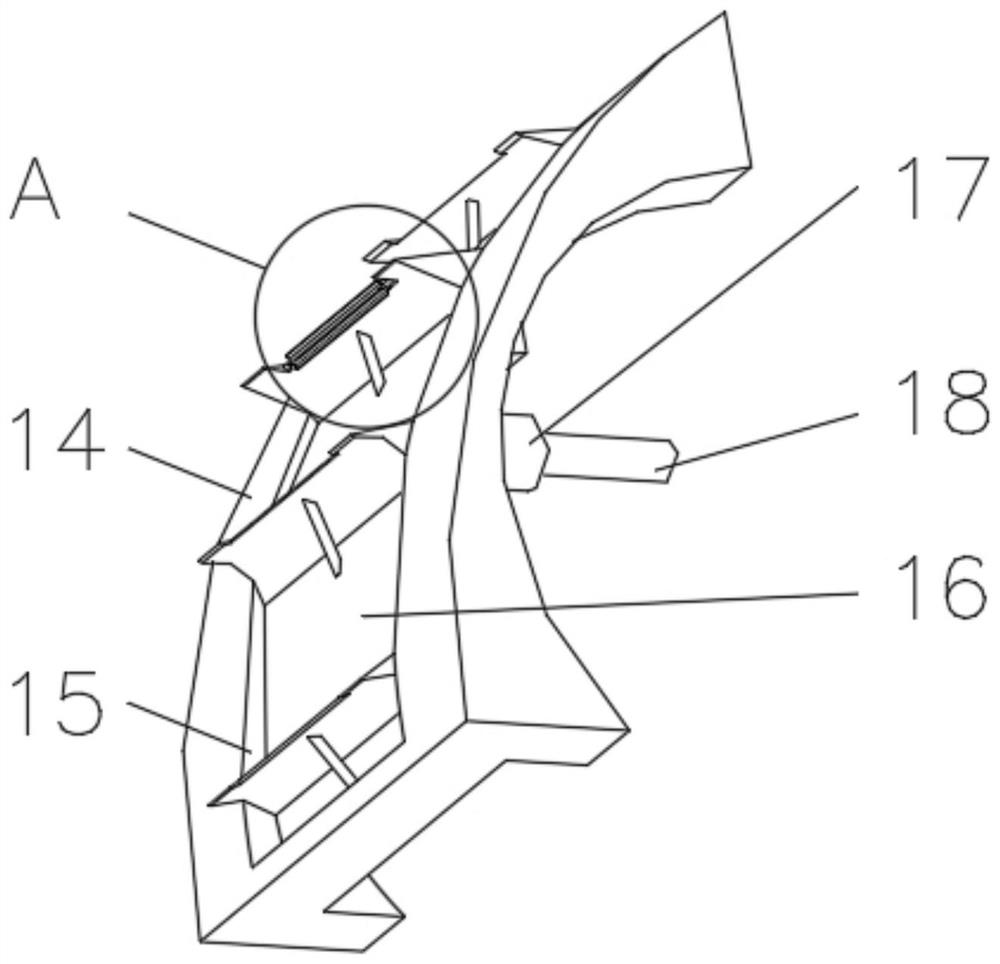

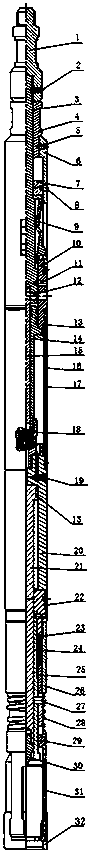

Underground throttle fishing tool and operation method thereof

PendingCN107676054ASimple structureEasy to operateBorehole/well accessoriesDischarge pressureFuel tank

The invention provides an underground throttle fishing tool and an operation method thereof. The underground throttle fishing tool comprises a pressure control mechanism and a fishing mechanism in vertical connection, wherein the pressure control mechanism mainly comprises a jar stem, a guide pipe, a shear pin, a small oil cylinder, a piston rod, a protection tube, an oil bag, a control valve, a large oil cylinder, an oil return assembly and an ejecting rod; after a fishing part grips the fishing neck of an underground throttle, and a jolting tool upwards jolts, the shear pin is sheared off; an elastic sheet type one-way claw is released; in the repeated lifting and placing pressurization deblocking process, the underground throttle downwards moves to a next oil pipe coupling gap; the elastic sheet type one-way claw pops up and hangs the fishing tool; and the lifting and placing pressurization is continuously performed until a center rod of the throttle is thoroughly unblocked. The underground throttle fishing tool and the operation method have the advantages that the structure is simple; the operation method can be easily implemented; a clamping jaw and a rubber sleeve of the throttle can be thoroughly unblocked by compressing the center rod of the throttle; the problem of low fishing success rate of the existing underground throttle is solved; and the technical and economic requirements of safety, reliability and low cost in the fishing process of the underground throttle can be met.

Owner:PETROCHINA CO LTD

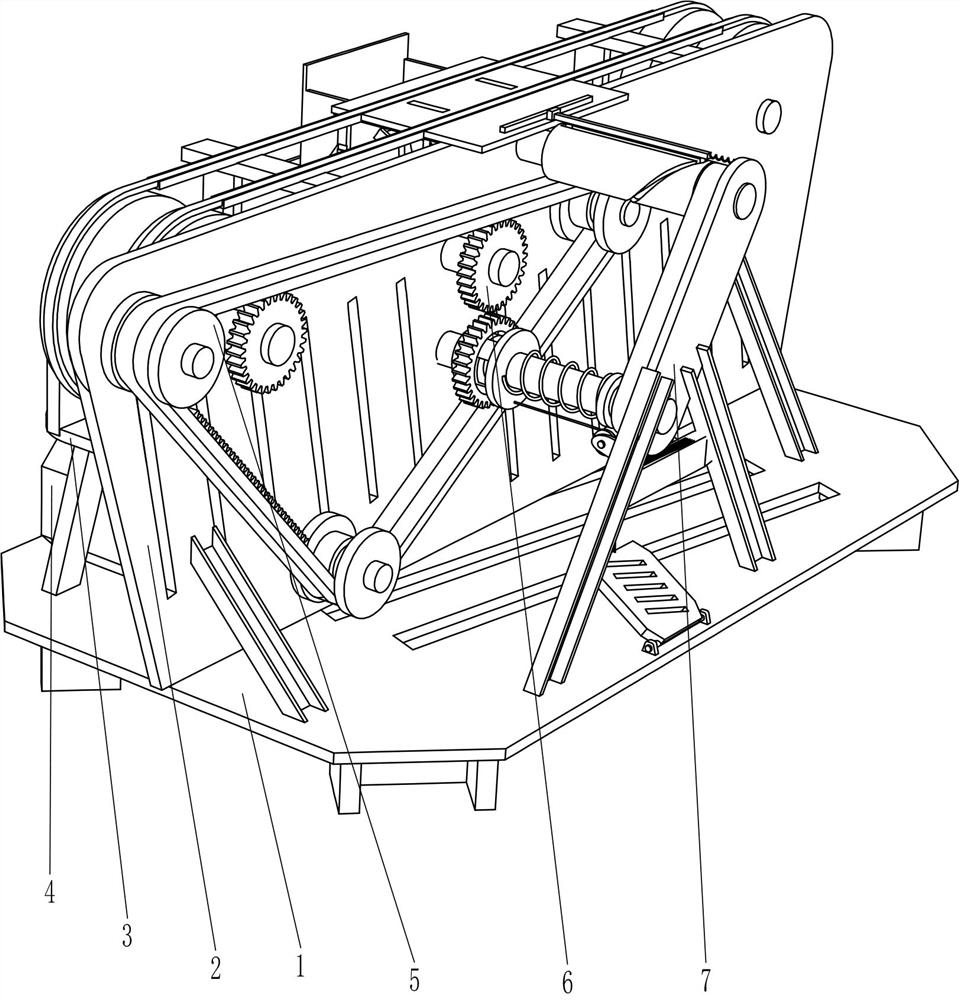

Cleaning and screening device for processing chestnuts

PendingCN110102481AReduce work intensityAvoid affecting follow-up workFood treatmentGradingOff designEngineering

The invention discloses a cleaning and screening device for processing chestnuts. The cleaning and screening device for processing chestnuts comprises a box, wherein a conveyor belt group I and a conveyor belt group II are fixedly arranged at the bottom of the inner wall of the box; the ends of the conveyor belt group I and the conveyor belt group II are in transition connection by a transition plate which is slantwise arranged; a spraying pipe is arranged on the top of the box and is located on the conveyor belt group I; a plurality of spraying heads are equidistantly arranged on the sprayingpipe; a draining box is also arranged at the bottom of the inner wall of the box and is located below the conveyor belt group I; the conveyor belt group II comprises a conveyor belt a and a conveyorbelt b which are spaced and arranged in a non-parallel manner; the included angle between the conveyor belt a and the conveyor belt b is gradually increased in the horizontal direction; the chestnutsare advanced on gaps of the conveyor belt a and the conveyor belt b; and four collecting boxes for collecting the chestnuts are arranged under the conveyor belt group II along the advancing directionof the conveyor belt group II. The cleaning and screening device can integrate the cleaning and screening of the chestnuts, saves space and improves the screening precision; and the input cost of thedevice is increased by utilizing the conveyor belt off-design.

Owner:ANHUI HE YI FOOD CO LTD

Pressing type clay brick manufacturing device

PendingCN112606191AAvoid affecting follow-up workEasy to collectFeeding arrangmentsAuxillary shaping apparatusAgricultural engineeringStructural engineering

The invention relates to a manufacturing device, in particular to a pressing type clay brick manufacturing device. According to the pressing type soil brick manufacturing device, people need to quickly manufacture soil into bricks, operation is convenient, the working efficiency is high, cracks are not prone to being generated, and the quality is good. The pressing type clay brick manufacturing device comprises a base, two supporting columns and a feeding mechanism, wherein two supporting plates are installed on one side of the base; the two supporting columns are installed on the base; and the feeding mechanism is installed between the base and the supporting plates and used for conveying soil. A proper amount of soil is poured into the feeding mechanism, the feeding mechanism is started to operate, and the feeding mechanism operates to drive the soil to move rightwards into a brick manufacturing mechanism to be extruded into bricks; and meanwhile, the feeding mechanism operates to drive the brick manufacturing mechanism to operate, the brick manufacturing mechanism operates to push out the bricks, so that people do not need to manually manufacture the soil into the bricks, operation is convenient, and the working efficiency is high.

Owner:杨正克

System and method for accurately controlling dosage of external carbon source

PendingCN114798111ASmall particle sizeAvoid affecting follow-up workSievingScreeningThermodynamicsAuger

The system comprises a smashing box and a smashing assembly arranged in the smashing box and used for smashing coal, a screening assembly used for screening the coal is arranged below the smashing assembly, and a discharging opening used for discharging is formed in the middle of the bottom of the smashing box. The lower end of the discharging port communicates with a horizontal pushing barrel used for conveying coal, a pushing auger used for horizontally conveying the coal is arranged in the horizontal pushing barrel, and the left end of the pushing auger is connected with a feeding motor used for driving the pushing auger to rotate. When coal is added, the coal is firstly crushed, the particle size of the coal is well controlled, the feeding consistency at the corresponding flow speed is guaranteed, the feeding precision is improved, cyclic crushing is further achieved, the situation that follow-up work is affected due to accumulation of materials at the screening position is avoided, and practicability is high.

Owner:YIKANG TECH CO LTD

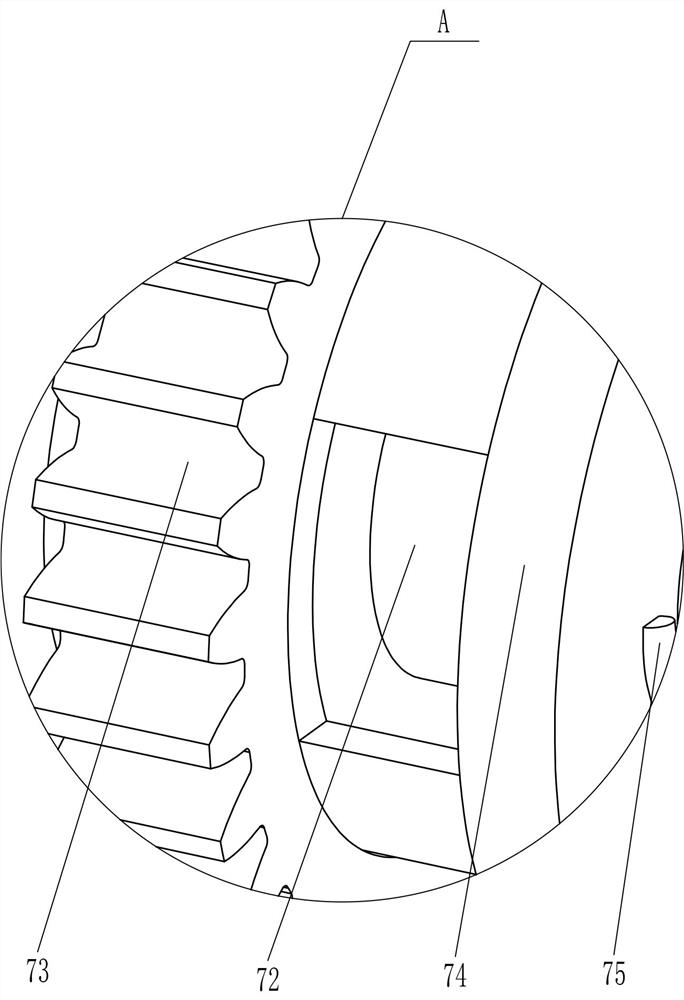

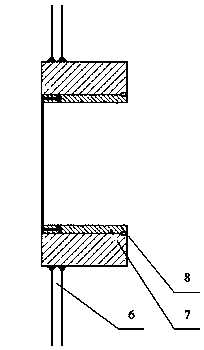

A mounting process of a lifting unit for a jack-up drilling platform

ActiveCN108894202APrevent deviationPrevent deviation from setting of pile fixing frameArtificial islandsUnderwater structuresFixed frameEngineering

The invention discloses a mounting process of a lifting unit for a jack-up drilling platform, the lifting unit comprises a motor and a gearbox arranged in front and back, one end of the motor is arranged flush with one end of the gearbox, A gearbox includes a gear shaft, a torque plate disposed transversely and horizontally of the gear shaft and disposed between the gear shaft and the transmissionmember, the torque plate is arranged perpendicular to the gear shaft, The outer sleeve of the gear shaft is provided with a climbing gear, which is characterized in that the climbing gear comprises asliding shaft sleeve, a cleaning lifting unit, a preliminary installation lifting unit, a pile fixing frame cleaning, a lifting unit traction device positioning, a lifting unit traction device removing, a lifting unit torque plate mounting, a bearing seat cover plate mounting, a lifting unit adjustment pad mounting, and a lubrication pipeline arranging. The invention has the advantages of simpleand orderly steps, improving working efficiency, and ensuring the firmness and stability of the connection between the lifting unit and the pile fixing frame.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

Turnip shredder

ActiveCN110236429AAvoid affecting follow-up workImprove work efficiencyKitchen equipmentElectrical and Electronics engineering

The invention relates to a shredder, in particular to a turnip shredder. The turnip shredder can shred turnips instead of manpower, the follow-up work can be prevented from being affected by hand ache, and turnip strips with different lengths can be obtained by shredding according to requirements. According to the technical scheme, the turnip shredder comprises supporting legs, a charging frame, a discharging pipe, a mounting plate and the like, wherein the supporting legs are symmetrically arranged on the left side and the right side of the outer side of the charging frame, the bottom of the charging frame is provided with a discharging opening, the bottom of the charging frame is connected with the discharging pipe, and the discharging pipe communicates with the interior of the charging frame. A servo motor is started to enable a cylinder to rotate, then turnips are in contact with the cylinder, the turnips are shredded into strips through shredding holes when the cylinder rotates, and a user does not need to take a shredder by hands to shred the turnips, so that the working efficiency is high, and the follow-up work is prevented from being affected by hand ache; and through a feeding device, the turnips do not need to be held by hands to be shredded, so that operation is more convenient, and the turnips can be shredded into turnip strips with different lengths.

Owner:山东万物生机械技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com