Bulk sand barrel loader

A barrel filling machine, sand filling technology, applied in conveyors, loading/unloading, transportation and packaging, etc., can solve problems such as affecting work, easy arm soreness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

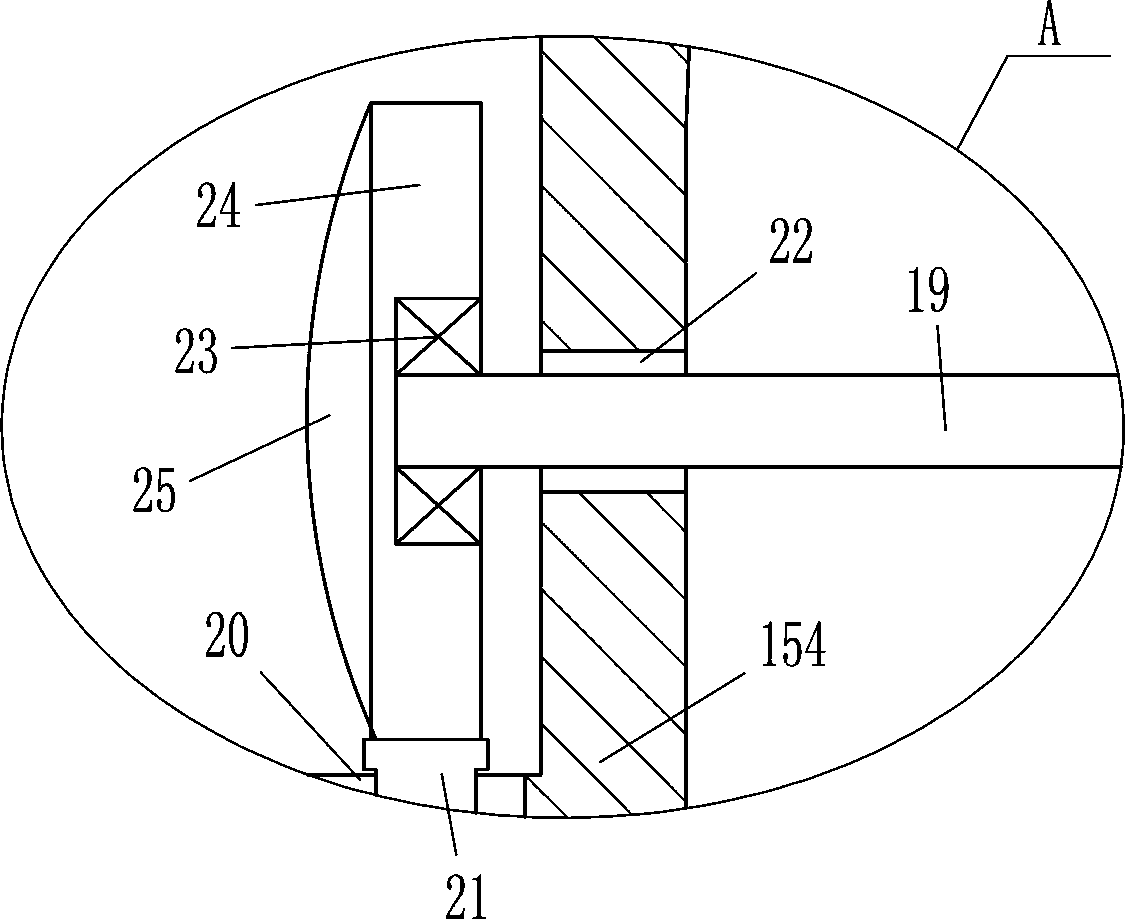

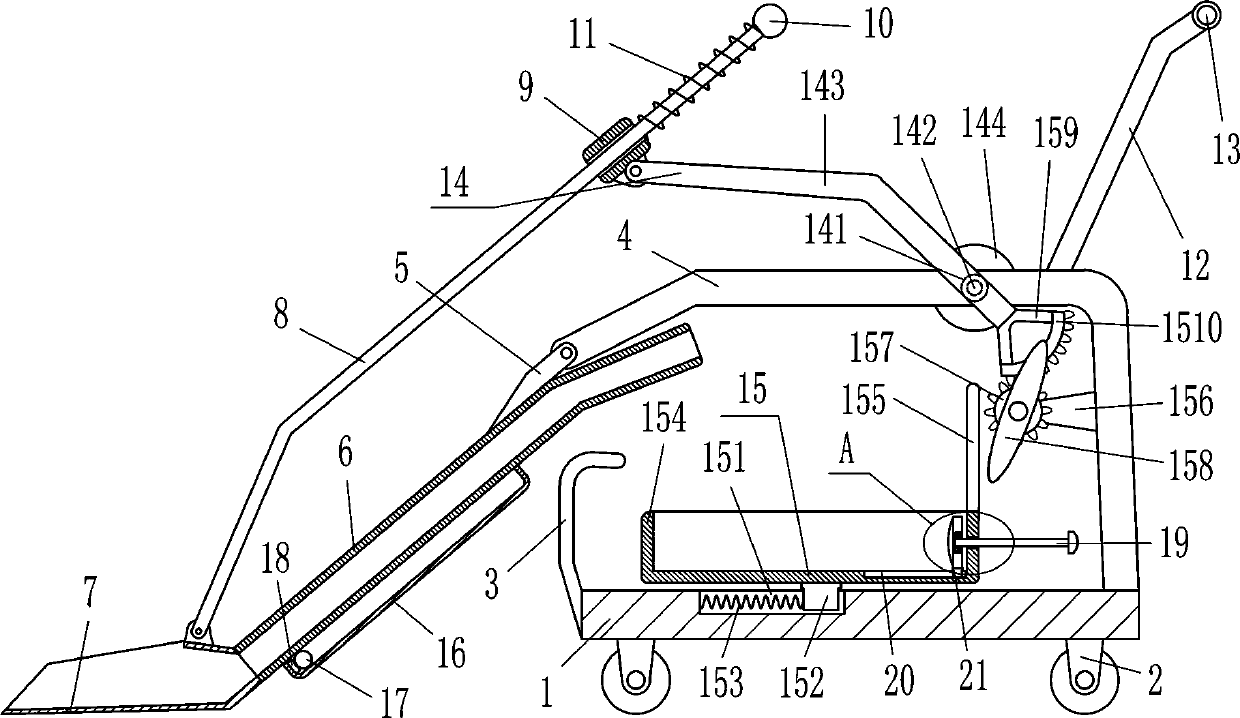

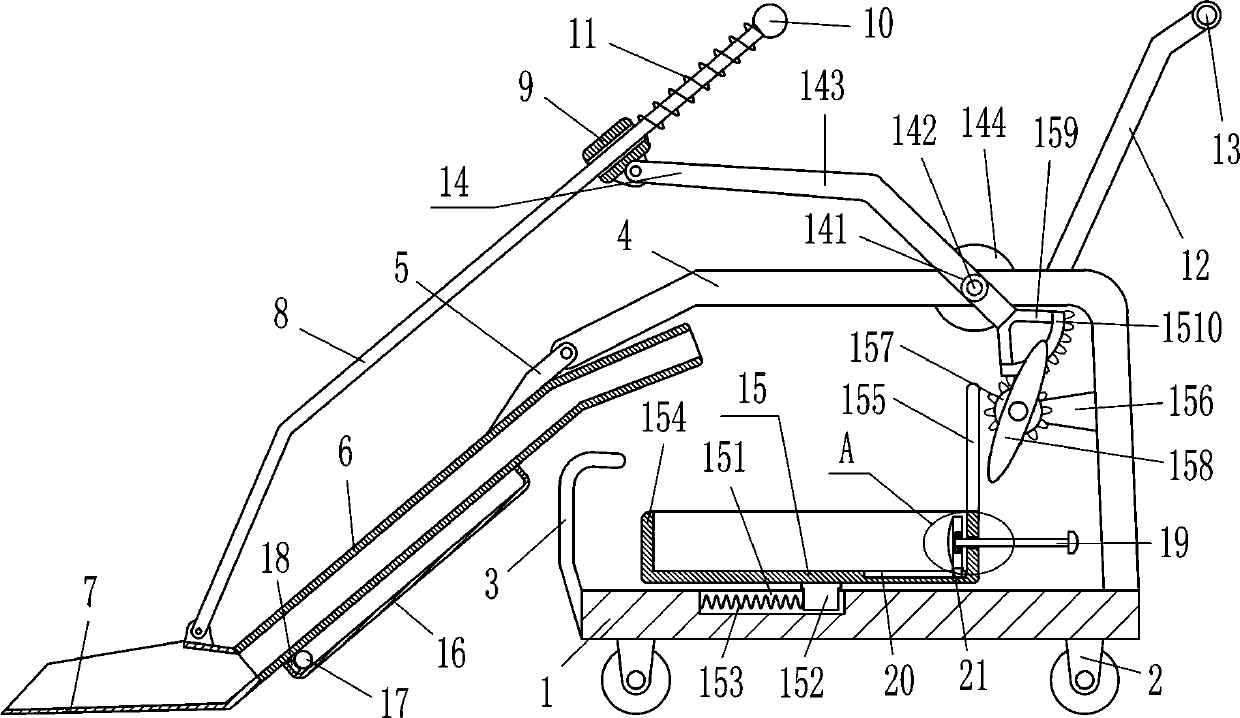

[0015] A kind of bulk sand barreling machine, such as figure 1 As shown, it includes bottom plate 1, wheel 2, 7-type baffle plate 3, 7-type frame 4, connecting rod 5, movable pipe 6, bucket 7, movable rod 8, sliding sleeve 9, limit ball 10, first spring 11. Support rod 12, grip rod 13 and driving device 14. Wheels 2 are installed symmetrically on the left and right sides of the bottom of the bottom plate 1. The bottom plate 1 is connected to the wheels 2 by bolts, which can prevent the sand bucket from falling. Type 7 The baffle plate 3 is installed on the left side of the base plate 1. The 7-type baffle plate 3 is connected to the base plate 1 through bolt connection. The top right side of the base plate 1 is fixed with the 7-type frame 4. 4 connection, the left end of the 7-type frame 4 is hinged with a connecting rod 5, and the bottom end of the connecting rod 5 is fixedly connected with a movable pipe 6 that can make the sand flow. The movable pipe 6 is located above the 7...

Embodiment 2

[0017] A kind of bulk sand barreling machine, such as figure 1 As shown, it includes bottom plate 1, wheel 2, 7-type baffle plate 3, 7-type frame 4, connecting rod 5, movable pipe 6, bucket 7, movable rod 8, sliding sleeve 9, limit ball 10, first spring 11. Support rod 12, grip rod 13 and driving device 14. Wheels 2 are installed symmetrically on the left and right sides of the bottom of the bottom plate 1, and the 7-type baffle plate 3 that can prevent the sand bucket from falling is installed on the left side of the bottom plate 1. The bottom plate 1. The right side of the top is fixed with a 7-type frame 4, the left end of the 7-type frame 4 is hinged with a connecting rod 5, and the bottom of the connecting rod 5 is fixed with a movable tube 6 that allows sand to flow. The movable tube 6 is located above the 7-type baffle 3 , the bucket 7 is installed on the left end of the movable pipe 6, the left side of the outer top of the bucket 7 is hinged with a movable rod 8, and t...

Embodiment 3

[0020] A kind of bulk sand barreling machine, such as figure 1 As shown, it includes bottom plate 1, wheel 2, 7-type baffle plate 3, 7-type frame 4, connecting rod 5, movable pipe 6, bucket 7, movable rod 8, sliding sleeve 9, limit ball 10, first spring 11. Support rod 12, grip rod 13 and driving device 14. Wheels 2 are installed symmetrically on the left and right sides of the bottom of the bottom plate 1, and the 7-type baffle plate 3 that can prevent the sand bucket from falling is installed on the left side of the bottom plate 1. The bottom plate 1. The right side of the top is fixed with a 7-type frame 4, the left end of the 7-type frame 4 is hinged with a connecting rod 5, and the bottom of the connecting rod 5 is fixed with a movable tube 6 that allows sand to flow. The movable tube 6 is located above the 7-type baffle 3 , the bucket 7 is installed on the left end of the movable pipe 6, the left side of the outer top of the bucket 7 is hinged with a movable rod 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com