Turnip shredder

A technology for shredding and radishes, which is applied in the field of radish shredders, can solve problems such as low work efficiency, affecting work, and easy soreness, and achieves the effect of high work efficiency and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

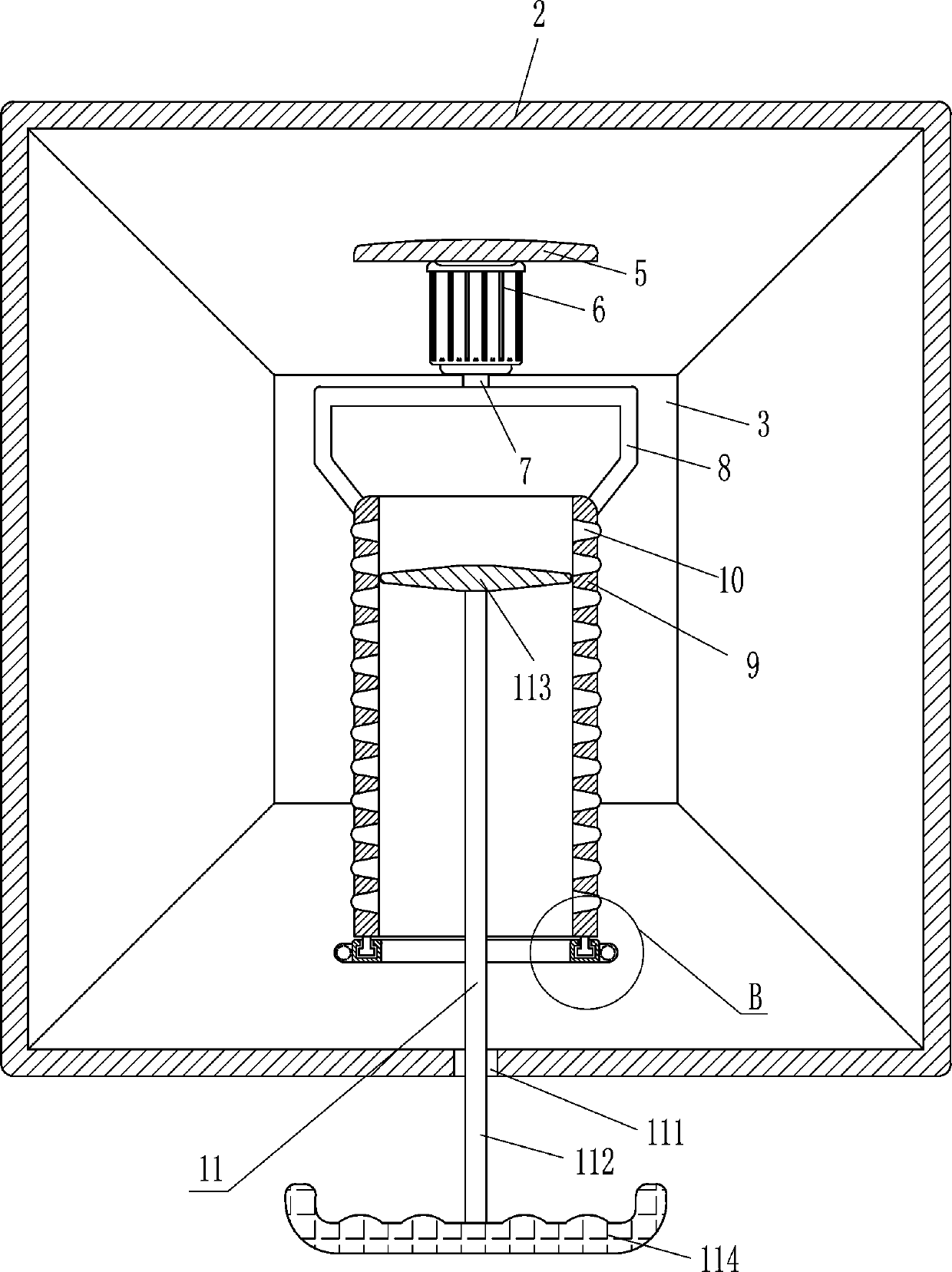

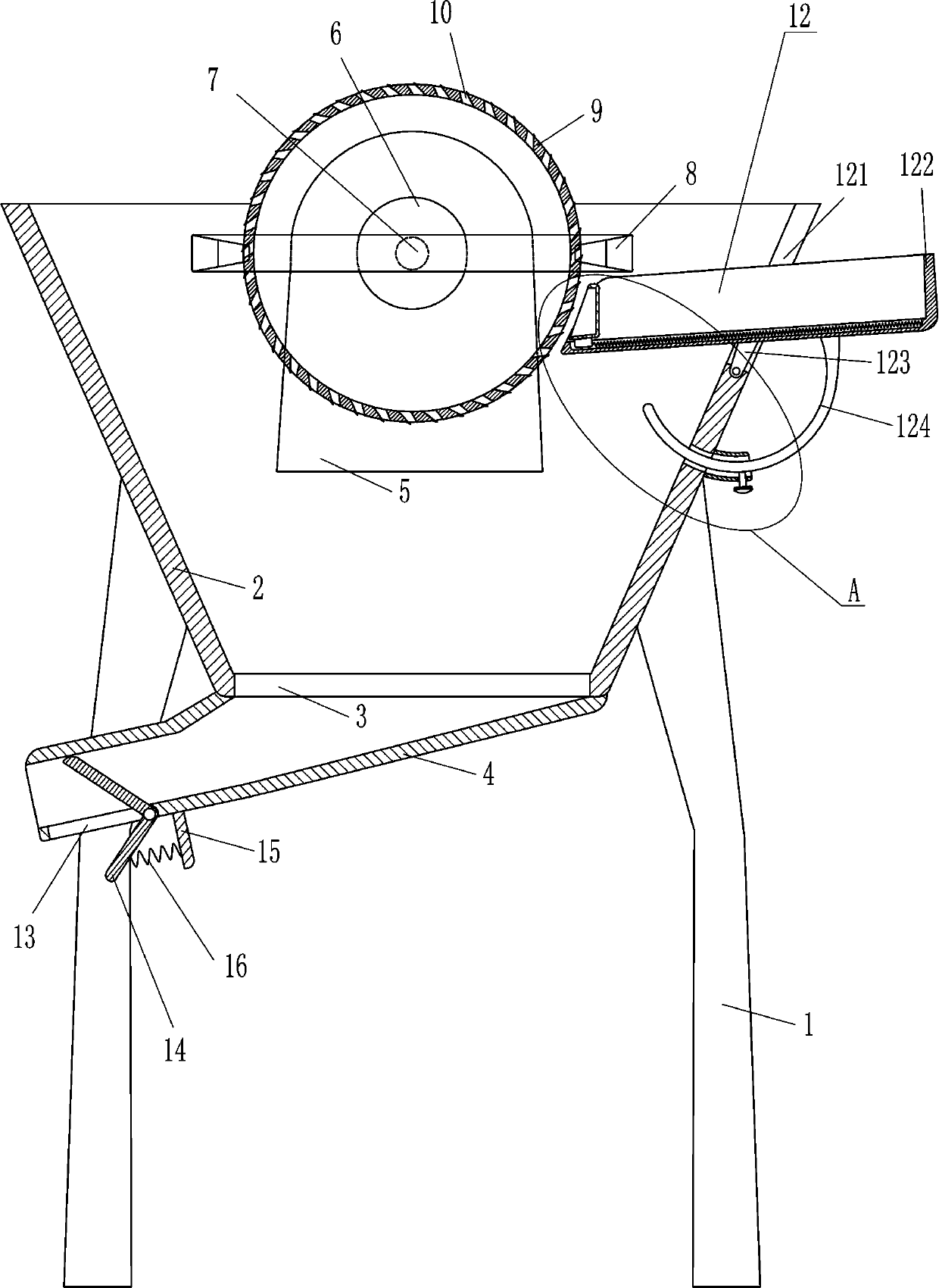

[0017] A radish grater such as Figure 1-2 As shown, it includes a leg 1, a charging frame 2, a discharge pipe 4, a mounting plate 5, a servo motor 6, a first rotating shaft 7, an n-shaped frame 8, a cylinder 9 and a pushing device 11, and the charging frame 2 Outriggers 1 are symmetrically arranged on the left and right sides of the outside, and the charging frame 2 is connected to the outriggers 1 through bolt connection. The bottom of the charging frame 2 has a discharge port 3, and the bottom of the charging frame 2 is connected to a discharge pipe 4 , the discharge pipe 4 communicates with the charging frame 2, and the rear side of the charging frame 2 is provided with a mounting plate 5, and the charging frame 2 is connected with the mounting plate 5 through bolt connection, and the front side of the mounting plate 5 is provided with a servo motor 6. The mounting plate 5 is connected to the servo motor 6 through bolt connection. The output shaft of the servo motor 6 is p...

Embodiment 2

[0019] A radish grater such as Figure 1-2 As shown, it includes a leg 1, a charging frame 2, a discharge pipe 4, a mounting plate 5, a servo motor 6, a first rotating shaft 7, an n-shaped frame 8, a cylinder 9 and a pushing device 11, and the charging frame 2 Outriggers 1 are symmetrically arranged on the left and right sides of the outside, and the bottom of the charging frame 2 is provided with a discharge port 3. The bottom of the charging frame 2 is connected with a discharge pipe 4. The rear side of the frame 2 is provided with a mounting plate 5, the front side of the mounting plate 5 is provided with a servo motor 6, the output shaft of the servo motor 6 is provided with a first rotating shaft 7, and the front end of the first rotating shaft 7 is provided with an n-shaped frame 8, an n-shaped A cylinder 9 is arranged between the left and right ends of the front side of the frame 8, and a plurality of grater holes 10 are evenly spaced on the cylinder 9, and a pushing de...

Embodiment 3

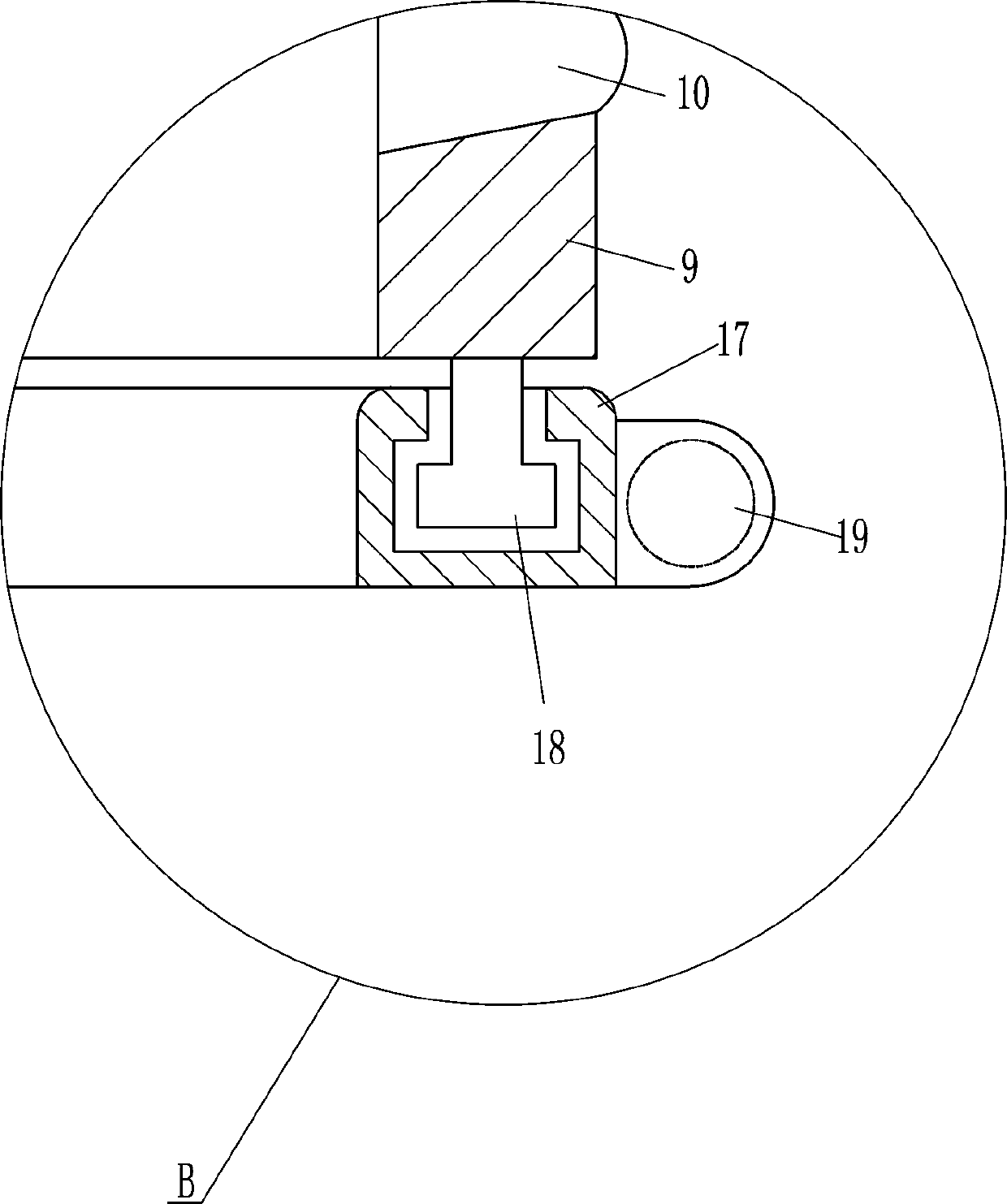

[0022] A radish grater such as Figure 1-3 As shown, it includes a leg 1, a charging frame 2, a discharge pipe 4, a mounting plate 5, a servo motor 6, a first rotating shaft 7, an n-shaped frame 8, a cylinder 9 and a pushing device 11, and the charging frame 2 Outriggers 1 are symmetrically arranged on the left and right sides of the outside, and the bottom of the charging frame 2 is provided with a discharge port 3. The bottom of the charging frame 2 is connected with a discharge pipe 4. The rear side of the frame 2 is provided with a mounting plate 5, the front side of the mounting plate 5 is provided with a servo motor 6, the output shaft of the servo motor 6 is provided with a first rotating shaft 7, and the front end of the first rotating shaft 7 is provided with an n-shaped frame 8, an n-shaped A cylinder 9 is arranged between the left and right ends of the front side of the frame 8, and a plurality of grater holes 10 are evenly spaced on the cylinder 9, and a pushing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com